Description

Automation and control plc - PAL’TOUCH®

Dosing, micro-dosing, traceability, supervision, background

As a designer of complete production lines, Palamatic Process associates ergonomically and visually programmed PLCs with its production units.

Production monitoring is as important as the result. This is why Palamatic Process’s automation and computer engineers include fool-proofing in raw material inputs, lot traceability, operator identification and dosing reliability. The production line steering screens provide ergonomics and comfort with continuous dialogue during the project execution phase between your production team and our design office.

Palamatic Process has its own electricity design office to meet all your needs. The electricity department is involved in preliminary design to help define your needs and guide you in many technical choices. It performs the following actions:

- Realization of electrical diagrams with SeeElectrical

- Definition and material control

- Reading and analysis of customer specifications.

The electrical engineering department works in close collaboration with the wiring workshop and the automation department. The wiring workshop has the following missions:

- Wiring and connection of electrical cabinets

- Wiring and connection of industrial control and power equipment

- Testing of cabinets and detection of electrical failures

- Electrical tests of equipment during acceptance

The automation design office is the guarantor of the proper functioning of your industrial automatons. In conjunction with the design office, it carries out the following operations:

- PLC programming (Siemens under TIA PARTAL V15, Schneider under Unity and SoMachine, Rockwell under CCW and Logic designer)

- Creation of operator screens (Siemens, Schneider, Rockwell, Beijer)

- Creation of supervision notices

- Analysis of customer specifications

- Permanent search for technical solutions

- Permanent updates of our programming standard.

- Our automation staff will visit your plant to install your equipment.

The documentation provided includes all operating and maintenance procedures. It allows your teams to optimally manage your industrial production line.

Equipment advantages

- Stamping of raw material feeds

- Batch traceability

- Identification of operators

- Dosing reliability

Media

View our equipment in videos

Pal'Touch® - Industrial automation

Pal'Touch® - Industrial automation

View our equipment in photos

Pal'Touch® control cabinet Palamatic Process

Pal'Touch® control cabinet from Palamatic Process equipped with a touch screen for production traceability.

Pal'Touch® Palamatic

Pal'Touch® control cabinets for remote control of the production line.

Automated systems and instrumentalization

Industrial automation enables the operator to control the equipment via a control screen. The process is thus automated, avoiding any human intervention.

Pal'Touch® automaton

Control screen to control the various machines.

Automation control cabinet

Electrical cable for control systems.

Industrial automation and instrumentalization

PLC management screen (start-up, flow, commercial weighing, etc...).

Industrial automation Pal'Touch® raw ingredients handling

A turnkey solution for your comfort:

- Wiring and connection of electrical cabinets

- Wiring and connection of industrial control and power equipment

- Testing of cabinets and troubleshooting of electrical failures

- Electrical tests of equipment during acceptance

Production line control box

Our automation collaborators come to your factory to install your equipment.

Industrial production line automation

- Realization of electrical diagrams with SeeElectrical

- Definition and material control

- Reading and analysis of customer specifications.

Wiring tests on control cabinet

Performing input/output tests: checking the proper functioning of the sensors and all actuators (motors, cylinders, valves, etc.).

Electrical control cabinet powder processing

- Wiring and connection of electrical cabinets

- Wiring and connection of industrial control and power equipment

- Testing of cabinets and troubleshooting of electrical failures

- Electrical tests of equipment during acceptance

Pal'Touch® automation on sack discharging processing line

Automate, robotize, make your production process more reliable.

Bulk handling equipment automation

- Empty tests of the equipment (automatic tests without product)

- Tests with bulk materials

Industrial automation touch screen

We are involved in the automation of any industrial process and we are specialized in the implementation of automated solutions in the management of your process.

Pal'Touch®screen for process control

As a designer of complete lines, Palamatic Process combines its production units with ergonomically and visually programmed PLCs. These automated processes can operate without human intervention.

Pal'Touch® industrial automation

Industrial automation system for the control of big bag emptying stations.

Industrial mill control

Control PLC for a sugar grinding system.

Control screen on dosing skid

Dosing skid with control screen.

Monitoring screen for seed application

Seed discharge from sacks for refilling with integrated dosing.

Skid with dosing monitoring

Seed discharge from sacks for refilling with integrated dosing.

Control screen on big bag discharging station

- Coding of raw material introductions

- Batch traceability

- Identification of operators

- Reliable dosing reliability

Control panel on big bag discharging station

Emptying of polypropylene bags for truck filling.

Big bag filling station monitoring

Big bag packing line with a capacity of 40 big bags per hour.

Automation and electricity department

- Optimization of the process and ergonomics of HMIs (Human-Machine Interactions)

- Operator training

- Complete and have signed the acceptance report.

Electrical wiring

The electrical wiring is done in our workshops. All our control cabinets are tested on your equipment before shipment.

industrial production lines involving raw ingredients traceability

Palamatic Process PLCs are used to manage the traceability of your production.

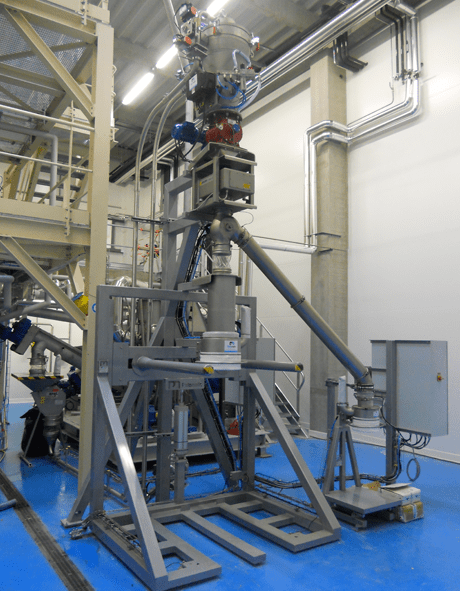

Automation on FlowMatic®03

Equipment integrated:

- FlowMatic® 03 - Big bag filling station

- Clamping ring

- PalSack® - Sack filling station

- Drop through rotary valve

- Magnetic detector

- Industrial automation

Mixer with industrial automation

Horizontal mixer (ploughshares/blades) with industrial automation and access platform.

Control screen for production line control

Control cabinet with touch screen for big bag filling station monitoring.

Bulk materials production line monitoring

Pal'Touch® technology: programmable controllers for precise raw ingredients production monitoring.

Control cabinet

Programmable industrial PLC.

Palamatic Process ATEX control cabinet

Palamatic electrical control cabinet specially designed to meet ATEX standards.

Pal'Touch® PLC

The Pal'Touch® PLC will allow you to optimally control your production tool on the production line.

Pal'Touch® - Industrial automation solution

Simple and intuitive control screen on the Pal'Touch® PLC equipped with a stylus.

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Loading of kneaders

Processed powders: salt, flour, milk powder, sugar, ascorbic acid - Loading of kneaders - Worldwide company specialized in industrial bakery.Food and Animal Feed

Pharmaceutical loading

Processed powder: Sorbitol - Pharmaceutical loading - Manufacturing of basic pharmaceutical products, medicinesFine chemical

Instant chocolate powder

Powder processed: chocolate powder - Instant chocolate powder - This company in the agri-food sector produces chocolates, sweets, condiments, seasonings, sugars...Food and Animal Feed

Premix manufacturing

Processed powders: silica, wheat, carbonate - Premix manufacturing - The installation consists of a new mixing line for the production of natural additives for animal nutrition.Food and Animal Feed

Loading of activated carbon

Processed powders: activated carbon - Loading of activated carbon - Installation for the world's leading supplier of coal for energy purposes.Chemical

Truck and wagon loading

Processed powder: adipic acid - Truck and wagon loading - The installation is especially designed to meet all the customer's constraints, in particular operation of the installation at a flow rate of...Chemical

Bulk truck loading

Processed powder: polypropylene - Bulk truck loading - This powder handling line is designed to feed granules into trucks at a high rate of 25 t/h. The production requirement is to create neither...Chemical

Animal flour loading

Powders processed: feather flour, animal flour - Animal flour loading - Palamatic Process has set up a bulk bag packaging station with vibration and automatic releaseof the bulk bag.Food and Animal Feed

Sugar packing

Processed powder: white sugar - Sugar packing - The FlowMatic© 04 bulk bag filling station allows dust-tight packaging of all types of powders, limits dust emissions and automates the removal of the...Food and Animal Feed

Aromatic herbs conditioning

Processed powder: dried grass seeds - Seeds conditioning - Installation of a double discharge station: big bag emptying and container emptying for mixer feeding as well as a double filling station...Food and Animal Feed

Preparation of dried fruit recipes

Processed products: dried fruit - Preparation of dried fruit recipes - This installation involves the feeding of dried fruit to a mixer. The various dried fruits are stored in bags, boxes and big bags...Food and Animal Feed

Reactors loading

Processed bulk material: lithium fluoride - Reactor loading - High performance pneumatic vacuum conveying with dosing container for incorporation into pressurized reactors. Our customer, a Chinese...Chemical

Lime and mineral packing

Processed powders: lime + additives - Lime and minerals packing - The installation involves a FlowMatic® 05 big bag filling station with suspended weighing.Minerals and building

Handling of veterinary bulk solids

Processed bulk solids: veterinary powders - Loading of veterinary powders - Company specialized in animal nutrition and health: workshop for the preparation and mixing of bulk materialFood and Animal Feed

Disperser feeding

Processed bulk materials: pyrogenic silica, calcium carbonates, expanded graphite, aerosil, imersil - Disperser feeding - The facility consists of a bag dump station fitted with a dedusting device and...Chemical

Automated drum dumper

Powder processed: wet ground powder - Automated drum dumper - Dumping and discharging of drums of wet ground powder at a rate of 40 drums/hour.Chemical

Blower for feeding containers

Processed materials: crushed egg shells - Blower for feeding containers - The purpose of the equipment is to collect crushed egg shells from a centrifuge / crusher placed downstream of automatic...Food and Animal Feed

Discharge, Feed and Grinding Line

Processed bulk material: Lysine - Grinding Line - Facility for one of the world's leading animal nutrition companies.Food and Animal Feed

Frozen fruit process

Processed bulk solids: blackcurrent, cherries, bananas, raspberries, peaches - Frozen fruit process - IQF (Individually Quick Frozen) big bag and cardboard box discharger.Food and Animal Feed

Mixing and packing of spices

Processed powders: spice mixtures (curry...), tea and herbal tea blends, fine salt - Spice blending and bagging - Bagging station for packaging spice and powder blends in bags from 1 to 25kg.Food and Animal Feed

Deconditioning of food powders

Processed powders: wheat starch, potato starch, salt, egg white and sugar - Deconditioning of food powders - The customer is a Breton cannery specialized in the manufacture of surimi.Food and Animal Feed

Raw material dosing

Processed powders: milk powder, salt, sugar and additives - Raw material dosing - This project concerns the deconditioning of raw materials in big bags for the feeding of 2 Viennese pastry production...Food and Animal Feed

Powder incorporator feeding system (powder/liquid mixer)

Processed powder: Mallow powder with a bulk density of 0.5 kg/m³. - Powder incorporator feeding system (powder/liquid mixer) - The purpose of the installation is the vacuuming of mallow powder for...Fine chemical

Perlite conveying

Processed powder: perlite - Perlite unloading, dosing and conveying - This mineral handling facility consists of an EasyFlow® 125 big bag deconditioning station.Minerals and building

Manufacturing of engine additives

Treated powder: diatomaceous earth - Manufacture of engine additives - Safe incorporation of powders with nitrogen inerting sluice in a sensitive environment, ATEX gas zone, zero retention.Chemical

Barrel filling with chemical agents

Processed materials: hydrazine hydrate derivative - Drum filling with chemical agents - The customer is the world leader in chemistry for the manufacture of building materials.Chemical

Incorporation of detergent products

Processed bulk materials: Benzotriazole and Tolytriazole - Incorporation of detergent products - The client is the Europe's leading supplier of household cleaning products and private brand toiletry...Chemical

Recycling of milk powder by micronization

Processed powder: dairy product flakes, density 400 to 500 µm - Recycling of milk powder by micronization - The installation consists of the dosing, transfer, grinding and reconditioning of the milled...Food and Animal Feed

Polyamide production line

Processed material: polyamide, nylon - Polyamide production line - This installation relates to an international group specialising in the manufacture of polyamides which wishes to set up an octabin...Chemical

Calcium carbonate loading

Processed Materials: calcium carbonate, aluminum oxide, titanium dioxide, silica - Calcium carbonate loading into storage tank - For this project our client company is a specialist in the manufacture...Chemical

Process for food supplements

Processed products: Vitamin A, Vitamin E, Metasmart dry - Process for food supplements - Big Bag filling station with integrated weighing and vibrating densification table.Food and Animal Feed

Pharmaceutical powder discharging process

Processed material: sodium bicarbonate - Powder processes in pharmaceutical laboratories - Deconditioning of raw materials (sodium bicarbonate for pharmaceutical application) from big bags.Fine chemical

Contained feeding of pharmaceutical ingredients

Processed material: titanium dioxide - Contained feeding of pharmaceutical ingredients - Big bag discharge by vacuum pipe for the contained feeding of pharmaceutical ingredients.Fine chemical

Manufacture of glass wool

Material handled: sodium nitrate beads - Manufacture of glass wool - The client, a world leader in insulation solutions, required installation of a pneumatic conveying system for the transfer of...Chemical

Oil filter recycling

Handled products: oil filters - Oil filter recycling - Recycling installation for a company involved in waste managementChemical

Tank feeding

Processed powders: Cobalt Carbonate, Cobalt Hydroxide & Cobalt Oxalate - Tank feeding - The purpose of the installation is to feed a preparation tank with the product packaged in big bags.Energy

Milk powder mixing line

Processed powder: infant milk powder - Milk powder mixing line - The mixing line is totally cleanable with the complete dismantling of the equipment with our Palamatic-EasyClean range of equipment.Food and Animal Feed

Dissolution of urea

Processed materials: liquid urea - Dissolution of urea - The 500m² facility consists of the production unit, polypropylene and HDPE storage tanks and storage of solid urea big bags.Water and smoke

Laundry powder packaging

Processed powders: detergents and washing powders - Laundry powder packing - Packaging of powdered finished products in 20, 25 and 30 kg bags.Chemical

Multi-format tipper

Product treated: drained automotive filters - Our client specializes in the collection and treatment of industrial wastes.Chemical

Transfer and bagging of plastic parts

Products treated: caps for medical use - Transfer and bagging of plastic parts - The customer is a manufacturer of needle caps for the pharmaceutical industry.Fine chemical

Sugar grinding unit

Processed powders: icing sugar from white granulated sugar and starch - Sugar milling unit - The installation consists of feeding the mill with granulated sugar and then packaging the resulting icing...Food and Animal Feed

Double confined EasyFlow® EF200 big bag emptying station

Products processed: solid coal rods - Double confined EasyFlow® EF200 big bag emptying station - The installation concerns two big bag unloading stations for high-speed, semi-automatic deconditioning...Minerals and building

Filling of truck with cement

Processed product: cement - Filling of truck with cement - Two EasyFlow® EF100 big bag unloading stations for high-speed semi-automatic unpacking.Minerals and building

Grinding and packaging of finished products

Processed products: dried insects - Grinding and packaging of finished products - Workshop for processing and packaging products for the animal nutrition sector.Food and Animal Feed

Manufacturing line for petfood industry

Processed Powders: Soy Flour, Brewer Yeast, Corn Starch, Dried Whey... - Manufacturing line for petfood industry - Manufacturering of dry and liquid flavor enhancers for the pet food industryFood and Animal Feed

Weighing, conveying, dosing and transfer

Products processed: snack cakes (starch, rice flour, oats) - Weighing, conveying, dosing and transfer - Extraction from big bags and sacks to feed a kneading tank.Food and Animal Feed

Unloading and conveying of cement

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton big bags with pneumatic transfer of material to silo storageMinerals and building

Automated big bag filling system

Treated powder: spodumene - Big bag filling for lithium battery production - Automated solution with minimal operator intervention.Minerals and building

Repackaging in drums and small big bags

Processed powder: Dextrose Anhydride - Repackaging in drums and small big bags - The installation is a complete turnkey line allowing the repackaging of dextrose from big bags into plastic drums or...Fine chemical

Production of polyethylene flakes

Processed powder: polyethylene - Production of low-density polyethylene - Company in the petrochemical industry: Installation of 2 big bag packaging lines.Chemical

Confined deconditioning, dosing and transfer of powders

Processed powders: Minerals and additives (such as titanium dioxide) for the manufacture of paints - Emptying of big bags into mobile IBCs with dosing and transfer of the product to a mixer downstream...Chemical

Autonomous manufacturing of a AdBlue by modular container process

Processed product: Solid Urea - AdBlue manufacturing by containerized process - Powerbarge / factory ship in New Caledonia.Water and smoke

Mixing and packing line for dried fruits

The dried fruit recipe preparation line allows you to: - load a paddle mixer with ingredients packaged in boxes - mix the different raw materials according to the recipe - transfer the dried fruit...Food and Animal Feed

Loading of big bags of fly ash

Processed powder: fly ash - Filling of big bags for building materials via gravity discharge from a silo.Minerals and building

Automation of the feeding of zinc powder to the process

Processed powders: zinc powder and additives. The aim is to improve the manual loading of the powders and to implement a complete automated system for accurate dosing of the ingredients into the...Energy

Loading big bags of soda ash

Treated powder : Natural soda ash - Automatic big bag filling line with buffer hoppers. Remote control system ensuring traceability and safety of the process.Chemical

Manufacturing process for sealants

Processed powder : Sodium hypophosphite - Manufacture and installation of a new turnkey process line for the production of coatings and sealants in an ATEX hazardous location.Chemical

Process for the production of chocolate

Process materials: granulated Sugar, whey, skim milk powder, and various other minor additives - Process for the production of chocolate - Objectives: unloading, transfer, storage and dosing of...Food and Animal Feed

High-rate big bag unloading system for the plastics and polymer industry

Processed powders: PET resin granules and PET flakes - Fully automated big bag discharging line - Big bag compaction at the end of the lineInsect breeding

Railcar unloading

Processed powders: tapioca starch, potato starch, corn starch - Unloading of railcars - Line for powder repackagingFood and Animal Feed

Cement deconditioning

Processed product: cement - Cement deconditioning - Autonomous bulk bag unloading system for the cement industryMinerals and building

Optimization of copper foil processes

Processed powders: carbon black, diatomaceous earth - The aim is to ensure perfect incorporation of these powders into the copper foil manufacturing process.Energy

Spice blending process

Products processed: spices - Spice mixing process - Improvement in dosing precision, ingredient traceability and overall productivity of the production process.Food and Animal Feed

Animal feed mixing process

Processed powders: minerals, vitamins, trace elements - Animal feed mixing process - Optimization of the preparation of product mixes on a manufacturing line using the DosingMatic® Master.Food and Animal Feed

Optimizing Bulk Bag Discharge with BFM® Fitting Connections

Powders handled: Pharmaceutical excipients and food ingredients - Optimizing Bulk Bag Discharge with BFM® Fitting Connections - Bulk Bag Discharge Solution with BFM® Fitting ConnectionsFood and Animal Feed

FlexMix® is a safe and flexible mixing solution for animal nutrition

Processed powders:sugar, sorbitol, locust bean gum, yeast derivatives, sodium chlorines Enhancing the safety and quality of feed supplements for livestock farmsFood and Animal Feed