Description

Weight or volume feeding for powders and granules - High precision

The screw feeders provide a steady flow, progressive and controlled your bulk powders retained in a hopper. The addition of load cells allows more accurate dosing and control of the production process.

Screw feeder range

4 standard models D10, D11, D12 and D13, with flow rates from 24 to 6,458 liters/h.

Palamatic Process powder feeders enable very high precision dosing of all bulk and raw materials with absolute safety.

| Models | D10 | D11 | D12 | D13 |

|---|---|---|---|---|

| Max theorical rates in l./h. | 24 to 142 | 89 to 523 | 261 to 1,438 | 1,174 to 6,458 |

-

Dosage accuracy5

-

Hygiene4

Loss-in-weight dosing assembly

Micro-feeder

High precision dosing

The microfeeders are designed for continuous and accurate dosing applications of powders and granules that tend to agglomerate or have poor flow characteristics.

3 standard models: MD01, MD02 et MD03 with a flow rate from 1 to 780 dm³/h.

MD microfeeders are used in all weighted or volumetric dosing installations. The body is made of polymer and/or food grade polymer. The other components are manufactured with 304L stainless steel, including bolts.

| Models | MD01 | MD02 | MD03 |

|---|---|---|---|

| Flow in liters per hour | 9 | 88 | 782 |

The Palamatic Process screw feeder can be configured on the manual dosing unit for pre-weighed micro-ingredients.

Equipment advantages

- Regularity of flow

- Anti bridging system included

- Product compliance

- Suitable for many materials

- Easy and quick cleaning

- Easy and quick maintenance

Media

View our equipment in videos

Screw feeder

The screw feeders provide a steady flow, progressive and controlled your bulk powders retained in a hopper. The addition of load cells allows more accurate dosing and control of the production process.

Industrial screw feeder

The screw feeders provide a steady flow, progressive and controlled your bulk powders retained in a hopper. The addition of load cells allows more accurate dosing and control of the production process.

Industrial feeding

The screw feeders provide a steady flow, progressive and controlled your bulk powders retained in a hopper. The addition of load cells allows more accurate dosing and control of the production process.

Screw feeder Palamatic Process

View our equipment in photos

Easyclean screw feeder

Carousel for weight gain dosing.

Range of screw feeders

D range of Palamatic Process screw feeders for the dosing of bulk materials of all kinds.

Weight screw feeder

The weight screw feeder provides controlled bulk material dosing.

Hygienic design screw feeder

Designed to facilitate easy dissassembly of the powder dosing unit to facilitate quick cleaning and maintenance.

Weight feeder

The D10, D11, D12 and D13 dispensers are compatible with the installation of servo load cells.

Palamatic Process Screw feeder

Screw feeder with internal agitator to promote material flow. The unit is designed for precise dosing in continuous or batch processes, with accuracy of +/- 2 grams in some applications.

Pneumatic valve

To stop the flow of bulk powders for increased accuracy and prevent the ingression of humidity from downstream processes.

Volumetric feeder

Palamatic Process screw feeders are the ideal solution for volumetric or gravimetric filling of bulk materials or raw ingredients.

Weight feeder

Dosing spiral on industrial screw feeder.

Palamatic Process weight feeder

3 dosing systems:

- Loss-in-weight feeder

- Gain-in-weight feeder

- Continuous feeder

Screw feeder - Tank filling

Metered feed of ethyl cellulose from a bulk bag unloading station into a reactor. The load time cycle is approx. 30 minutes, i.e., feed rate of 31.1 kg/hr

Volumetric screw feeder

Batching of food spices (curry) for the preparation of pre-prepared dishes.

Volumetric dosing Palamatic Process

The Palamatic Process volumetric screw dispenser is used to perform a uniform, progressive and controlled flow of your bulk materials retained in the hopper.

Volumetric dosing bulk materials

The weight dosage is used to automatically introduce bulk materials by batch or continuously.

Weight feeder system

The industrial dosing unit is installed on a stable platform with a very precise weighing system. The system works by weight gain or loss and achieves an accuracy of 1%.

Sack discharging with screw feeder

Mobile dosing skid for seeds conveying.

D12 filler equipped with a flow meter

Screw filler on drum emptying skid.

Flow meter on screw feeder

Dosing device with extended dosing tube

Screw feeder bulk materials

Dosing system for sprinkling ethyl cellulose.

Bag dump station with screw feeder

3 types of dosing screws:

- Pig tail

- Ribbon helix blade

- Helix with inner tube

Bag dump station with screw feeder

3 types of dosing screws:

- Pig tail

- Ribbon helix blade

- Helix with inner tube

Pneumatic conveying and dosing

Complete conditioning system (feeder, weighed filling station) mounted on a mobile frame, facilitating the cleaning of the unit.

The mobile frame is positioned at the outlet of the magnetic separator. The connection is done manually by BFM® flexible fitting.

Screw dosing system

The installation consists of discharging bags of Ethylcellulose into a bag dump station and dosing the Ethylcellulose powder from this dump station to a gravitarily fed dissolution reactor (agitated vessel).

Palamatic Process screw feeder

Assembly is integrated on load cells to inform the process controls of the quantity metered for the bulk material. In order to avoid interference with the load cells, the dosing unit is connected to the downstream process via a flexible fitting flexible fitting.

Screw feeder with bearing pressurization

Screw feeder under weighing hopper.

Micro-feeder

Microfeeders are mainly used for continuous dosing of bulk materials and granules that are not very fluid and tend to agglomerate.

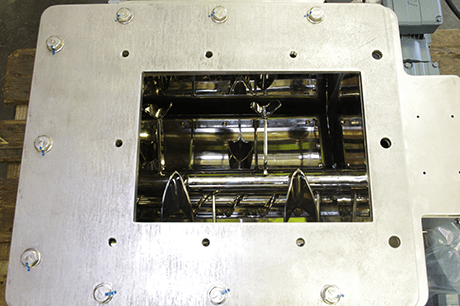

Internal view screw feeder

Internal view of the Palamatic Process powder feeder.

Weight screw feeder

For a controlled dosing of raw ingredients.

Loss-in-weight feeder

Dosing by weight is way of providing a precise feeding method by the weight of raw ingredients.

Screw feeder process

The hygienic design simplifies and shortens the cleaning process while optimizing its efficiency.

Screw feeder D11

The upstream dosing device fills the bag. The volumes are balanced via the double jacketed filling tube.

Screw feeder D11 Palamatic Process

Screw feeder for a mixing and packing line.

Pneumatic washing powder conveying

Discharge of big bags of bleaching agents for feeding a tank.

Peanuts screw feeder

Dosing of peanuts for continuous feeding of a grinding line.

Sack dumping with screw feeder

Deconditioning of milk powder for the production of dairy products.

D12 filler with air blowing at the bearing

Filling device equipped with a flow meter in the nuclear industry.

Sack dumping screw feeder Palamatic Process

Deconditioning of milk powder for the production of dairy products.

Micro dosing bulk materials

Preparation and dosing station for metal powders.

Pharmaceutical powder dosing

Preparation and dosing station for metal powders.

Features

Technical specification

Flow rates may be adjusted with the installed frequency regulator. In these applications, the motors integrate forced ventilation.

There are 4 models:

- D10: up to 142 l/h

- D11: up to 523 l/h.

- D12: up to 1,438 l/h.

- D13: up to 6,458 l/h.

| Models | Theorical flow | |||||

|---|---|---|---|---|---|---|

| Dosing tool | Hourly plage | Reducer ratio | Fixed speed throughput rate | Variable speed throughput rate (frequency variator) |

||

| Type | dm³/h. | 1/... | dm³/h. | dm³/h min. | dm³/h max. | |

| D11 | 1 - 4 - D | 0.7 | 10 15 (std) 28 40 |

98 65 35 24 |

14 9 7 3.5 |

70 48 25 17 |

| 3 | 0.6 | 10 15 (std) 28 40 |

82 56 29 20 |

12 8 4.3 2.6 |

60 40 21 15 |

|

| 5 | 0.64 | 10 15 (std) 28 40 |

90 60 32 22 |

13 8 4.5 3 |

64 43 23 16 |

|

| 7 | 0.95 | 10 15 (std) 28 40 |

133 88 47 33 |

18 12 6.5 4.7 |

95 64 34 23 |

|

| D12 | 1 - 2 - B | 0.7 | 10 15 (std) 28 40 |

798 530 399 285 199 |

108 74 57 40 28 |

570 382 285 205 143 |

| 3 | 0.6 |

10 |

616 410 308 220 154 |

84 57 44 31 21 |

440 295 220 158 111 |

|

| 4 - 5 - D - E | 0.64 | 10 15 (std) 28 40 |

1,036 688 518 370 259 |

140 96 74 51 37 |

740 496 370 266 185 |

|

| D13 | 1 - 2 - B | 5.7 | 10 15 (std) 28 40 |

3,640 2,418 1,820 1,300 910 |

494 338 260 181 130 |

2,600 1,742 1,300 936 650 |

| 3 | 4.4 | 10 15 (std) 28 40 |

1,904 1,265 952 680 476 |

258 177 136 95 68 |

1,360 911 680 489 340 |

|

| 4 - 5 - D - E | 8.4 | 10 15 (std) 28 40 |

4,158 2,762 2,079 1,485 1,039 |

564 386 297 208 149 |

2,970 1,990 1,485 1,070 742 |

|

Composition of the feeder:

1. Body

2. Homogenization tool ensuring perfect powder down flow

3. Output tube

4. Dosing screw

5. Sealing rings included, exchangeable

6. Support plates for gear motor attachment

7. Buffer hopper

Examples of installations:

Vacuum pneumatic conveying, manual sack dumping unit and bucket filling.

Technical characteristics of the micro-feeders MD

Our microfeeders are available in 3 versions:

- MD01: up to9 dm³/h.

- MD02: up to 88 dm³/h.

- MD03: up to 780 dm³/h.

| MD | NOMINAL THROUGHPUT RATE | |||||

|---|---|---|---|---|---|---|

| Feeder | Dosing tool | Hourly throughput rate | Reducer ratio | Fixed speed throughput rate |

Variable speed throughput rate (frequency variator) |

|

| Type | dm³/h | dm³/h | dm³/h min. | dm³/h max. | ||

| MD01 | 5 | 0.1 |

15 |

9 3 |

-- | -- |

| MD02 | 1 - 4 | 0.7 | 15 40 (std) |

65 24 |

9 4 |

48 18 |

| 3 | 0.6 | 15 40 (std) |

56 20 |

8 3 |

40 14 |

|

| 5 | 0.64 | 15 40 (std) |

59 22 |

8 3 |

42 16 |

|

| 7 | 0.95 | 15 40 (std) |

88 33 |

12 5 |

62 24 |

|

| MD03 | 1 - 2 | 5.7 | 15 40 (std) |

530 199 |

74 28 |

382 143 |

| 3 | 4.4 | 15 40 (std) |

410 154 |

57 21 |

295 111 |

|

| 4- 5 | 8.4 | 15 40 (std) |

782 294 |

120 41 |

615 212 |

|

Dimensions:

| MD | A | B | C | D | E | F | G | H | ØT | ØU | ØV | ØW | X | Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | 155 | 134 | 150 | / | 211 | 32.5 | / | 54 | 80 | 15 | / | / | 77.0 | 8 |

| 02 | 302 | 250 | 215 | 642 | 312 | 62.5 | 327.5 | 100 | 160 | 42 | 70 | 60 | 107.5 | 19 |

| 03 | 470 | 415 | 390 | 920 | 390 | 144.5 | 465.5 | 135 | 300 | 76 | 130 | 120 | 201.0 | 85 |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Manufacture of coated peanuts

Processed bulk solids: roasted/caramelized peanuts - Manufacture of coated peanuts - This factory develops and markets chocolate based products.Food and Animal Feed

Spice dosing

Processed powder: spice mixture with an apparent density of 500 kg/m³ - Spice dosing - The customer was looking to replace his manual dosing system, in the small-size packaging room, with a weight...Food and Animal Feed

Skid for metallic powder

Processed powders: metallic powder (bulk density 5) - Skid for metallic powder - The powder is vacuumed from its initial packaging and stored in a drying tank.Chemical

Hair cream manufacturing

Processed powders: potassium persulphate and sodium persulphate - Hair cream manufacturing - A major French industrial group manufacturing cosmetics products wanted to install a new production line in...Fine chemical

Natural food flavours

Processed powders: apetence factors, natural food flavours - Natural food flavour - The company, which is specialized in the manufacture of flavours for domestic animal feed, was looking to install a...Food and Animal Feed

Aromatic herbs conditioning

Processed powder: dried grass seeds - Seeds conditioning - Installation of a double discharge station: big bag emptying and container emptying for mixer feeding as well as a double filling station...Food and Animal Feed

Discharge, Feed and Grinding Line

Processed bulk material: Lysine - Grinding Line - Facility for one of the world's leading animal nutrition companies.Food and Animal Feed

Deconditioning of food powders

Processed powders: wheat starch, potato starch, salt, egg white and sugar - Deconditioning of food powders - The customer is a Breton cannery specialized in the manufacture of surimi.Food and Animal Feed

Incorporation of detergent products

Processed bulk materials: Benzotriazole and Tolytriazole - Incorporation of detergent products - The client is the Europe's leading supplier of household cleaning products and private brand toiletry...Chemical

Disinfectant packaging

Processed powders: sodium carbonate, acid... - Disinfectant packaging - Production line of cleaning products for the maintenance of livestock buildings.Chemical

Injection of sodium bicarbonate

Bulk material processed: sodium bicarbonate - Injection of sodium bicarbonate - The Palamatic Process pin mill plays an important role since the grain size has a direct impact on the efficiency of the...Water and smoke

Foundation production line

Processed powders: silica and iron oxide - Foundation manufacturing line - The aim of the installation is the mixing and homogenization of the different ingredients.Fine chemical

Recycling of milk powder by micronization

Processed powder: dairy product flakes, density 400 to 500 µm - Recycling of milk powder by micronization - The installation consists of the dosing, transfer, grinding and reconditioning of the milled...Food and Animal Feed

Dried tomato powder process

Processed product: dried tomato powder - Industrial process for tomato products - The application requested by the customer is the filling of big bags and cartons at the outlet of the atomization...Food and Animal Feed

Preparation of spice mixtures

Processed products: spices - Preparation of spice mixtures - The objective is a spice blending line with cleanability of the equipment and recipe flexibility.Food and Animal Feed

Dosages of Dry Mix products

Processed powders: whey, sugar, flavorings - Dry products dosing for dry mixing - Preparation line for the manufacture of ice cream with unitary dosage of different ingredients according to the recipe...Food and Animal Feed

Powdered sugar bagging

Processes powder: powdered sugar - Powdered sugar bagging - Our client is a company specializing in sugar manufacturing with a need to increase production capacity to meet the rising demand by global...Food and Animal Feed

Weighing, conveying, dosing and transfer

Products processed: snack cakes (starch, rice flour, oats) - Weighing, conveying, dosing and transfer - Extraction from big bags and sacks to feed a kneading tank.Food and Animal Feed

Production of polyethylene flakes

Processed powder: polyethylene - Production of low-density polyethylene - Company in the petrochemical industry: Installation of 2 big bag packaging lines.Chemical

Process for feeding mixers

Processed powders: potato flakes, semolina, salt, breadcrumbs - New workshop for the production of fillings - Unloading, transfer, storage, dosing.Food and Animal Feed

Black mass treatment process

Treated powder: black mass - Black mass treatment process - Process to unload the black mass from big bags, precisely dose and repulp it with water, without clogging reactions or dust emissions from...Energy

Drum unloading enclosure

Processed product: Triuranium octoxide (U3O8) – Drum tipping station - The installation concerns the installation of a production system that empties, transfers and doses drums of a toxic product...Energy

Process for mixing dry ingredients

Processed Materials: Granulated Sugar, Rebaudioside M, Cocoa Powder and various minor ingredients - Process for mixing dry ingredients - The new facility expansion project required the capabilities of...Food and Animal Feed

Turnkey solution for the screening, dosing and filling sacks with toxic materials

Treated powder: Lithium nickel manganese cobalt oxide - Turnkey solution for sieving, dosing and filling 22 kg bags of toxic powder. Improvement of ergonomics and operator safety.Energy

Optimization of copper foil processes

Processed powders: carbon black, diatomaceous earth - The aim is to ensure perfect incorporation of these powders into the copper foil manufacturing process.Energy

Spice blending process

Products processed: spices - Spice mixing process - Improvement in dosing precision, ingredient traceability and overall productivity of the production process.Food and Animal Feed

Feeding a multi-ingredient mixing line

Products processed: accelerators, antioxidants, anti-ozone, vulcanization agents, pigments, plasticizers, reinforcing agents and resins - Supply of a multi-ingredient mixing line - The objective of...Chemical

Automation of the feeding process

Products processed: gluten flour, ascorbic acid, emulsifiers, enzymes, seeds and yeasts - Automation of the feeding process - Improvement of the preparation of premixes, quality and production...Food and Animal Feed

Animal feed mixing process

Processed powders: minerals, vitamins, trace elements - Animal feed mixing process - Optimization of the preparation of product mixes on a manufacturing line using the DosingMatic® Master.Food and Animal Feed