Description

CONTAINED MANUAL BAG DUMP - SACKTIP SE OEB - SUITABLE FOR TOXIC OR DANGEROUS PRODUCTS

Optional integrated dedusting

Made of steel or stainless steel

Sacktip® SE is a dump station suitable for handling toxic or dangerous bulk materials. The sealed door with glove box allows the total containment of the powder and the protection of the operators during the bags opening operations.

Contained manual sack discharging range

Drain for dangerous or toxic products:

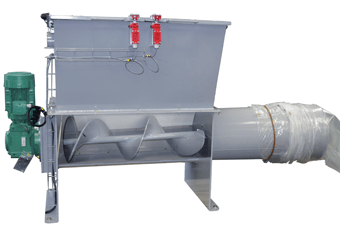

The SACKTIP SE OEB bag dump stations ensure the manual deconditioning of bulk materials that are delivered in bags at the production sites.

These bag dump stations, manufactured in steel or stainless steel and with an ergonomic design, allow the bulk materials to be stored and transferred to the production line without air contamination by dust emissions during the bag opening and discharge process. All cabins are equipped with dust extraction nozzles or integrated filters. Gloves, positioned on the glass door, allow to safely handle bags that contain dangerous or toxic materials.

The range of manual bag dump stations is ergonomically designed to provide a perfect solution for your manual unloading needs. Palamatic Process bag emptying stations are designed to significantly reduce the risk of air pollution by dust emissions during the manual bag opening and discharge process.

All bag dump stations are equipped with dust extraction nozzles or integrated filters

Operation procedure:

The operator places his bag on a laterally arranged roller conveyor and introduces it into the machine body on the screen provided for this purpose. Sliding bars facilitate the introduction of the bag into the heart of the machine. He can then open the bag and empty it. Once it is completed, the operator evacuates the empty bag to the compactor on the side opposite the roller train.

This machine is designed for the manual opening of all types of bags, limiting dust emissions by adding a dust removal unit and an empty bag compactor. Its ergonomic design ensures that the operator has an efficient and reliable workstation.

A dust extraction nozzle is provided on the top of the machine.

For parts in direct contact with the product and other parts that are not in direct contact with the product (door), the manufacturing materials to be defined are as follows: painted steel, stainless steel 304, stainless steel 316L, plexiglass, safety glass.

-

Rate2

-

Automation1

Equipment advantages

- Glove box for handling the product in a dust-tight container

- Holder for bag opening tool which is secured by its attachment cable

- Mirror polished finishing touches to improve product flow and ensure total hygiene

- Side bag evacuation chute to avoid cluttering the work area and store empty bags in a "confined dirty" area

- Perfect ergonomics

- Healthy working atmosphere

Media

View our equipment in photos

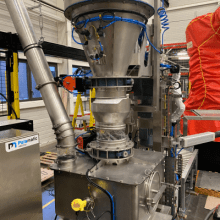

Sacktip® SE Palamatic Process

Discharging of bags with integrated glove box for handling the product in a vacuum: glass and gloves.

Gamme Sacktip SE

- Vidange de produits toxiques ou dangereux

- Parfaite ergonomie

- Atmosphère de travail saine

- Confinement poussé

- Protection des opérateurs

Sack manual discharging - Glove box

Glove box for handling bulk material in a closed container: glass and gloves.

Containment - sack discharging

Dust-tight door with glove box.

Contained manual sack discharging

Roller infeed conveyor - bulk material handling equipment.

Contained manual bag dump station

Mirror polished finish to improve bulk solids and raw materials flow and hygiene.

Powder processing bag dump station

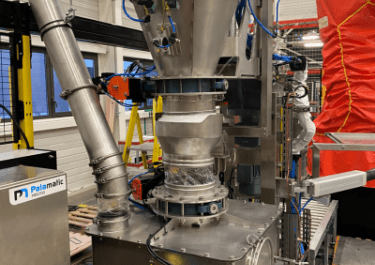

The bags can be introduced by a dust tight airlock valve system (other alternatives: belt conveyor, roller conveyor...)

Bag dump station

Ergonomics and containment for toxic bulk materials.

Sack discharging system

Airtight SAS for bag insertion.

Contained sack discharging

Secure opening tool with a holding cable.

Tracking of bags

For batch management and process safety.

sack manipulator

For effortless lifting and handling of the bag.

Contained manual bag discharging

The mirror polished finish is particularly suitable for the pharmaceutical sector.

Double bag emptying station - Glove box

The gloves are mounted on the door and are mounted on PVC glove rings.

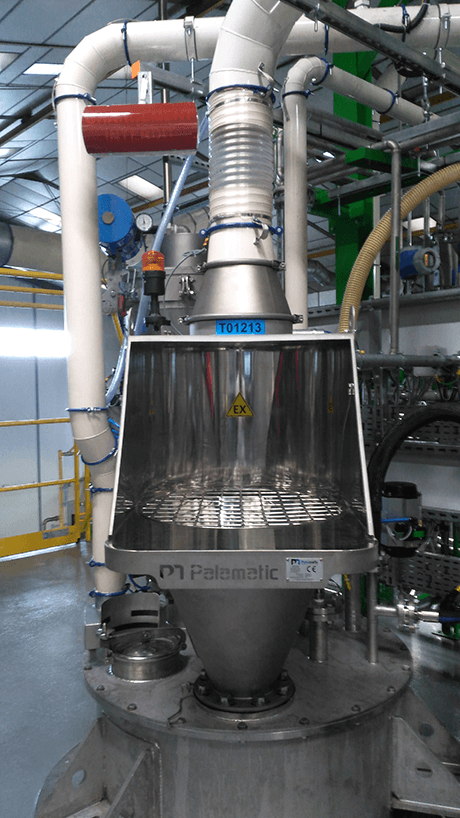

Bag dump station with dust collection

Dust extraction fan to maintain a healthy atmosphere.

Custom manual bag emptying

All equipment can be configured according to your requirements. The Palamatic Process design office is able to offer you very specific solutions.

Contained sack discharging

Dust tight manual bag dump station with a tight door with glove box.

Contained sack discharging - Food powder

Possibility of unpacking drums as an option.

Features

Technical specification

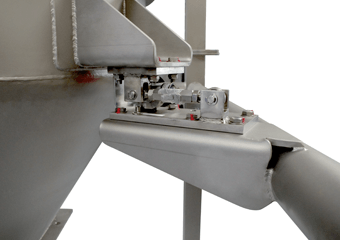

The door remains hinged by a gas cyliner and the compression of the door seal is carried out by clamps securing the closing. Thus, the closure is sealed.

A removable mesh screen at 50 x 50 mm with 2 mm diameter wire is placed above the powder chute. Sliding bars placed on the screen allow the operator to move his bag with a minimum of effort.

| Flow rate | 2 to 6 sacks/min. |

|---|---|

| Access door | Painted steel, 304L stainless steel, 316L stainless steel, plexiglass, anti-static lesan, tempered laminated glass |

| Manufacturing materials | Painted steel, 304L stainless steel, 316L stainless steel |

| Convoyor | Custom RAL, bead-blasting, electropolishing |

Gloves: latex, natural rubber, polyurethane, Hypalon, Butyl

Tightness: EPDM, NBR, natural rubber, silicone

Standard models of the range:

| Model | Length of the bags to be handled (in mm) | Flow rate for dust extraction nozzle (m³/h) |

Hopper water volume (Liters) |

Outlet diameter (DN) |

Height from ground to outlet flange (mm) |

|---|---|---|---|---|---|

| SE 800 | 650 | 400 | 180 | 250 | 285 |

| SE 1000 | 850 | 500 | 265 | 250 | 285 |

| SE 1200 | 1,050 | 600 | 265 | 250 | 285 |

| SE 1400 | 1,250 | 700 | 300 | 250 | 285 |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Loading tank

Processed powder: very dusty and toxic bulk material - Loading tank - The objective of the installation is to contain the powder to avoid any dispersion during the different stages of conveying.Chemical

Bag and drum handling

Processed powder: Potassium Bi-Fluoride - Drum and bag handling in the nuclear sector: 25kg kraft paper bags with an inner liner and 90kg drums with an inner liner.Energy

Natural food additives

Processed powders: sodium bicarbonate, strain (bacteria) - Natural food additives - This industrial production line consists of the installation of bag dump station Sacktip® SE 800.Food and Animal Feed

Contained feeding of pharmaceutical ingredients

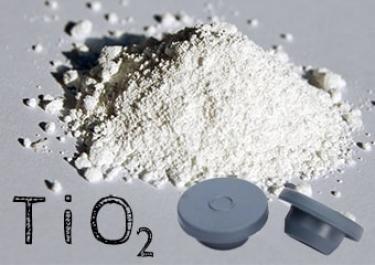

Processed material: titanium dioxide - Contained feeding of pharmaceutical ingredients - Big bag discharge by vacuum pipe for the contained feeding of pharmaceutical ingredients.Fine chemical

Unloading and conveying of cement

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton big bags with pneumatic transfer of material to silo storageMinerals and building

Secure and Optimize the Handling of Sensitive Powders in Industry

Powders handled: lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), which require secure handling due to their toxicity, hygroscopic nature, and...Chemical

Safe preparation of pyrotechnic powders: automated dosing and mixing line

Treated powders: ammonium perchlorate Safe preparation of pyrotechnic powders: automated dosing and mixing lineDefense