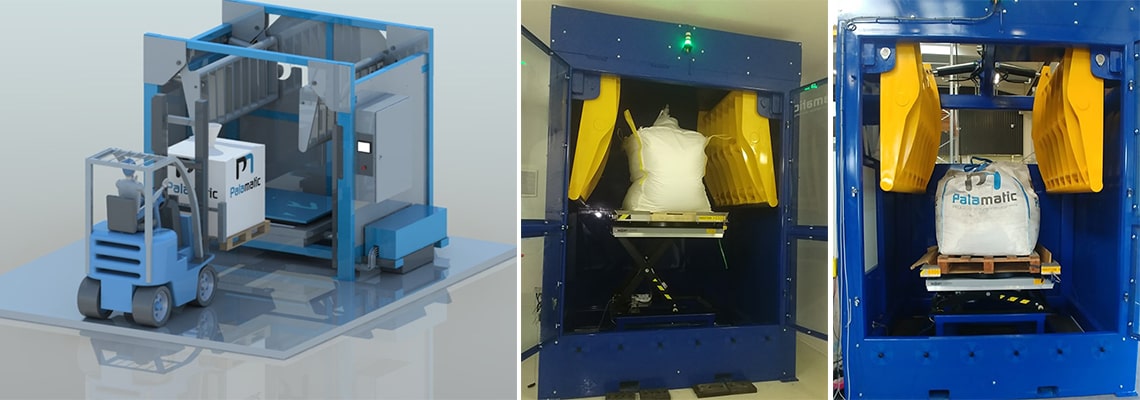

The Palamatic bulk bag conditioner is the ideal solution to ensure the discharging of all your bulk bags taken in mass. If your materials are agglomerated in bulk bag bags or if the flow is extremely difficult, the advantages of the hydraulic crusher bulk bag will convince you!

The increasing use of raw materials in bulk bags in factories obliges manufacturers to equip themselves with efficient solutions for discharging bulk bags.

Some products pose major problems during emptying because of their bulkiness. Sugar bulk bags, wax bulk bags, flake bulk bags or even wet product bulk bags generally have a high mass setting.

1. Safety at the dumping station

When you place a bulk bag on an emptying station and after opening the sleeve, the product does not flow, it is extremely difficult to correct this problem safely.

When this situation occurs, production operators have to take actions that are often perilous to trigger the flow. The operator, using a bar, tries to break the clods or, using the electric hoist, shakes the bulk bag... These operations can lead to incidents and, in some cases, serious accidents.

Emptying a caked bulk bag wastes time and may even lead to a supply failure. The operator in charge of the manoeuvre finds himself in a delicate situation since the open bulk bag is engaged on the emptying station. It is therefore difficult to remove it. Some Palamatic bulk bag discharging stations integrate pneumatic cylinders and vibrating plate solutions to help with the flow. When the product is heavily massed, the vibration or pneumatic massage options are not powerful enough to reliably unblock the situation. Upstream use of the hydraulic bulk bag crusher is the only solution for de-caking bulk bags.

Also, some forklift drivers may endanger their safety by breaking, hitting or massaging the bulk bag by shaking it, hitting it against a wall or post. This can cause the bulk bag to tip over, puncture the bulk bag or even damage the wall or post used as an anvil! The Palamatic solution of the bulk bag crusher is the right solution to these dangerous situations.

2. Multi-station use

The installation of a bulk bag crusher stand in the factory allows the mutualisation of the installation to all bulk bag emptying stations. Some bulk bag opening structures integrate autonomous bulk bag massaging solutions. When several emptying stations are required on the production site, the investment in an on-board massage system can quickly become expensive. Implementing a hydraulic bulk bag conditioner station makes it possible to integrate all types of bulk bag emptying stations without specific extraction aid options.

In addition, the performance of the bulk bag conditioner station is unmatched by on-board emptying station solutions.

The comparison in figures :

- A bulk bag crusher develops 60 tons against 3 tons for on-board massagers.

- The stroke of the massage arms of the hydraulic massage cage offers a 30% higher penetration stroke VS the pneumatic massagers of the dumping station.

If your require further assistance,

I am at your entire disposal.

Loïc, expert in bulk bag crusher

The massage of the bulk bags on the hydraulic crushing cage offers a dynamic massage which ensures a crushing of the bulk bag on all the height and on the 4 faces thanks to the use of the rotating lifting table. The bulk bag crumbling is controlled by an automatic cycle and programmed to break up the mass on all 4 sides of the bulk bag and over the entire height. The pneumatic bulk bag massagers installed directly on the emptying stations are fixed and therefore cannot massage the entire bulk bag.

Integrating a bulk bag crusher/hydraulic massage cage on your production site is the guarantee to extract all the products packed in bulk bags without risk for the operators.

3. Autonomous, movable and programmable big bag conditioner

The bulk bag crusher is a standard machine designed to be self contained and easily integrated into your production facility. The crushing pressure is 60 tons but Palamatic engineers have designed the system to have no dynamic force resultant on the structure's legs. Thus, this bulk bag conditioner can be installed directly on your floor or platform without any modification. Your massage cage only needs an electrical connection to ensure the crushing cycles of your bulk bags!

The bulk bag crushing station can be moved according to the option chosen in order to position it as close as possible to the bulk bag emptying stations.

Breaking up the bulk bags in a dedicated area or at a service provider's is now possible with Palamatic's hydraulic massage solution.

For your bulk bags taken in mass in an extreme way, a specific cycle is integrated offering a stronger penetration and intensity. Palamatic's extensive knowledge of powder handling has enabled us to design the most efficient crushing station for all your products in a wide range of industries.

To sum up, here are the advantages of the Palamatic bulk bags conditioners:

- Hydraulic massage on all 4 sides of the bulk bag

- Massage over the entire height of the bulk bag

- 60 tons of crushing pressure

- Standard automatic cycle

- Specific automatic cycle for extremely hard products

- Independent crumbling cage for your production process

- Suitable for all types of bulk bags

- ATEX version available

- Numerous options available: confinement of the massage cage, movable cage, loading by electric bulk bag hoist, autonomous loading by motorised roller conveyor, etc.

Contact one of our experts for a study on the implementation of a bulk bag conditioner in your production workshop or consult our dedicated article on the selection of your bulk bag filling system.