Case studies - Compound and plastic materials

The main objectives in the compound and plastic industry are as follows:

- Discharge and conveying of powders and bulk materials

- Continuous feeding of the extrusion line

- Preparation of the different materials by dosing, heating, premixing

- Installation in an indoor explosive zone called ATEX category 0-20 of equipment involving the handling of powders and bulk materials under controlled atmosphere (nitrogen, nitrogen).

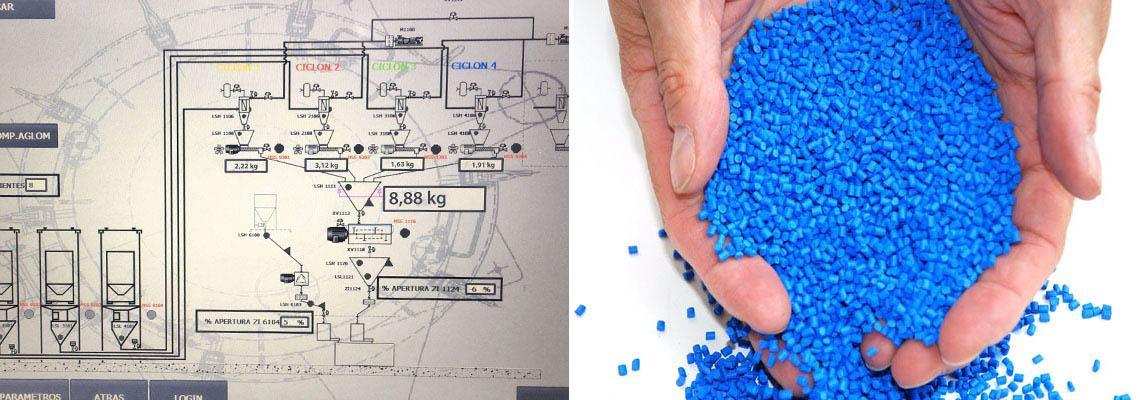

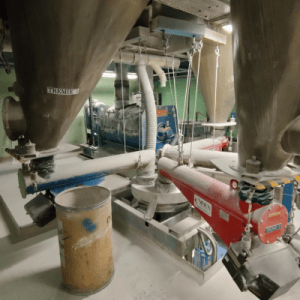

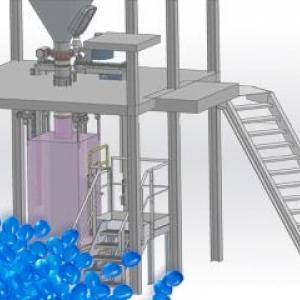

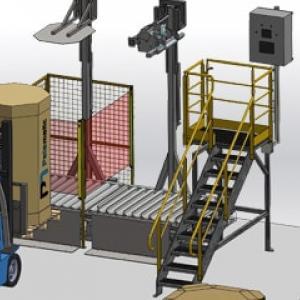

The storage of raw materials is generally carried out from stainless steel silos or from big bags with the integration of explosion protection (explosion vent, specific filters, hopper inerting). Weighed intermediate hoppers provide buffers for feeding the screw feeders. Weighted screw feeders ensure continuous and accurate feeding of the extruder. Pre-mixing lines (turbo-mixing) are installed upstream of the extrusion to ensure the handling and introduction of micro-ingredients. All the storage, deconditioning, conveying, weighing, dosing and control equipment is connected and controlled from the supervision room (PLC, control PC). In addition to the control function, the history (traceability) of the productions is archived.

Nos applications chez nos clients

Optimizing Sensitive Powder Processing with a Custom Solution

Powders Handled: Lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), requiring secure handling due to their toxicity, hygroscopic nature, and...