Case studies - Batteries and componants

Nos applications chez nos clients

Automated Bulk Bag Unloading and Conveying System for Lithium

Powders handled: Lithium Carbonate (Li₂CO₃), Iron Oxide (Fe₃O₄), Lithium

Optimizing Automated Bulk Bag Unloading for Lithium Powders

Energy

Optimizing Sensitive Powder Processing with a Custom Solution

Powders Handled: Lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), requiring secure handling due to their toxicity, hygroscopic nature, and...

Chemical

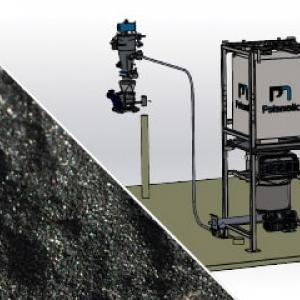

Automating bulk bag decompaction

Powders treated: hygroscopic powders such as metal sulphates

Optimizing the handling and unloading of super bags to improve safety and production

Energy

Complete line for breaking filter cake and bagging in super sacks

Processed powders: nickel hydroxide, nickel sulphate and sodium hydroxide

Recovery of nickel hydroxide cake for reconditioning in super sacks

Energy

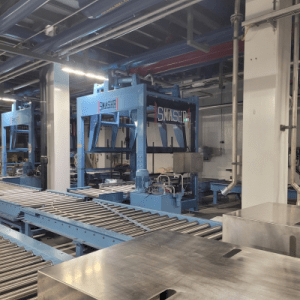

Complete automated lines for decompacting and emptying bulk bags

Processed powders: lithium, cadmium and oxides

Decompaction and emptying of bulk bags for battery manufacture

Energy

Sack filling system for the manufacture of batteries

Energy

Turnkey line for the manufacture of battery paste

Energy

Big bag emptying and dosing for the manufacture of copper collectors for electric batteries

Energy

Automated deconditioning of big bags to increase nickel hydroxide production

Energy

Disposal, dosing and pulping system

Energy

Automation of a super bag unloading system

Energy

Discharging station of big bags of cadmium in very high containment

Chemical

Handling big bags of toxic material for a battery manufacturer

Energy

Today the world of batteries is a rapidly evolving industry. For more than 20 years Palamatic Process has been providing this industry with material handling equipment for cadium and silicon, in the creation of winding film and manufacture of batteries. Our experience also lends itself in the knowledgeable design and implementation of screw feeders and dosing equipment for extruders. Furthermore, Palamatic Process is involved in the creation of premixes with the adjustment of product characteristics such as humidity, temperature and granulometry.

The Palamatic Process knowledge in powder management is further represented in the handling of "toxic" products often used in the manufacture of batteries, cells, supercapacitors, etc. Containment and dust removal in bag-in-bag-out are the technologies implemented for the realization of these battery projects.