Octabin discharging:

Octabin discharging - Octoflow 03

-

Rate3

-

Automation3

Octabin discharging - Octoflow® 02

-

Rate3

-

Automation3

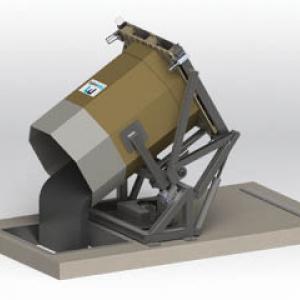

Octabin discharging - Octoflow® 01

-

Rate3

-

Automation3

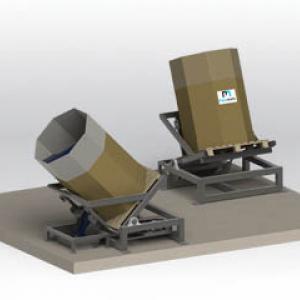

Palamatic Process has developed the OctoFlow® range for discharging your octabins.

The octabin emptying equipment is specifically designed to empty raw materials delivered in octabin or big bag. With a sturdy construction and a minimum floor space requirement, it is an easy-to-operate and safe to handle system. The control mechanism simplifies and optimizes the handling of the octabin dumping system with automatic regulation of the predefined settings, thus avoiding all readjustment operations during use.

This range features 3 models:

- Octabin dumper OctoFlow® 01: side discharge flap or suction pipe

- Octabin dumper OctoFlow® 02: pneumatic clamping with tilting by hydraulic unit

- Octabin dumper OctoFlow® 03: turnover of the octabin in the mobile base allowing a gravity discharge.

Octabins can be emptied manually or automatically.

Examples of treated powders: citric acid, urea, polyethylene, caramel, coffee, coconut, nylon, zinc, textile fibre, fructose, egg powder, barley, gluten...