Description

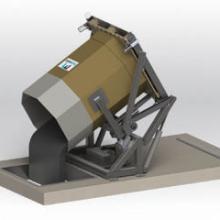

Octabin Unloading - Octabin tilting device - Octoflow 01

For octabins with side drain hatch.

This equipment for octabins has a side drain hatch or suction cane.

The FlowMatic Octabin model is ideal for semi-automatic deconditioning of octabins in gross weighing. It ensures the containment, the safety of use and the management of the commercial weighing.

The unloading station is a complete solution: dosing, packaging, conveying.

The presence of the capping tray allows the installation to be confined and dust removal (double casing filling head) to be optimized during the filling cycle. The styling tray is mounted on the station's apron and is therefore adjustable in height to fill different sizes of octabins.

-

Rate3

-

Automation3

Equipment advantages

- Deliverable in ATEX zone

- Customized version available

Media

View our equipment in photos

Octoflow 01

Octabin dumper OctoFlow® 01 for octabins with side discharge flap.

Octabin

Octabin for the storage of bulk materials and raw ingredients.

Octabins

Storage of bulk materials and raw ingredients in octabins.

Features

Technical specification

| Flow Rate | 10 to 30 octabins/h. |

|---|---|

| Rate | 1.5 tons/ octabin |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 1.5 kW |

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Power input | 0.2kW |

| Compressed air consumption | 0.7 kW |

| Operating pressure | 6 |

| TOR22 input | 2 |

| TOR ouput | 5 |

| Accuracy of the weighing chain | ± 500 grams |

| Dust removal rate | 300 m³/h. |

| Maximum size of octabins (Length x Width x Height) | 1,200 x 1,200 x 2,400 mm |

Integrated systems:

- Supply hopper (optional)

- Filling head

- Support structure

- Retractable access platform

- Densification vibrating table