Description

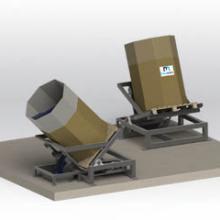

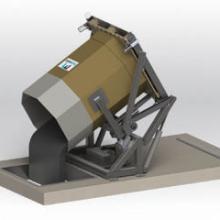

Octabins filling OC1 - Semi-automatic packaging

The FlowMatic® Octabin OC1 filling station enables high rate gross weighing to optimize the filling rate of your octabins. This model is ideal for semi-automatic packaging. It ensures the containment, the safety of use and the management of the commercial weighing. The filling station ensures high efficiency (rate: 10-30 octabins/h, capacity: 2 tons/octabins) and ergonomics of the station through a streamlining of operator interventions. The system therefore allows the packaging of large volumes ready for sale. The FlowMatic® Octabin OC1 filling station provides high speed gross weighing packaging to optimize the filling rate of your octabins.

The FlowMatic® Octabin OC1 Standard is the complete solution for automatic weighing for octabins (dosing/conditioning/conveying). It ensures the containment, the safety of use and the management of the commercial weighing.

Equipment advantages

- Vibrating table

- Handling conveyor

- Dosing and weighing

- Pallet unstacker

Features

Technical specification

| Rate | 10 to 30 octabins/h |

|---|---|

| Capacity | 2 tons/big bag |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 1.7 kW |

| Compressed air consumption | 0.7 Nm³/h |

| Dust removal rate | 300 m³/h |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 0.2 kW

Operating pressure: 6 bar

Input 4 - 20 mA: 1

Digital input: 2

Digital output: 5

Accuracy of the weighing chain: +/- 500 grams

Dimensions maximum octabins length * width * height: 1,200 * 1,200 * 2,400

Integrated systems:

- Vibrating densification table

- Retractable access platform

- Support structure

- Filling head

- Supply hopper (optional)