Palamatic Process has developed a complete range of robotic equipment for the automation of production processes, in order to meet the industrial requirements of our customers. Our solutions integrate cutting-edge technologies to guarantee efficiency, while respecting the most rigorous safety and quality standards. Our robots and cobots will assist you with your depalletizing or handling processes for drums, bags, barrels and boxes.

Our robotic equipment is distinguished by its modular design, allowing simplified maintenance thanks to quick disassembly systems and intuitive maintenance procedures. These devices can also be equipped with Cleaning-In-Place (CIP) solutions for automatic sanitation without interrupting production.

Our robotics range underlines Palamatic Process's commitment to offering tailor-made, high-performance solutions for the powder and granule handling industry. Through our expertise, we guarantee you increased results and productivity.

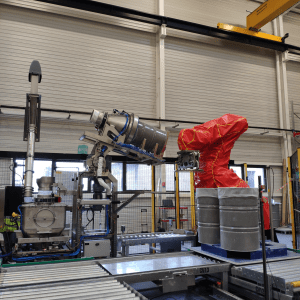

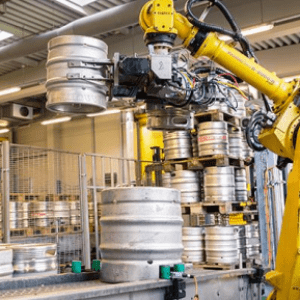

Palamatic Process robots and cobots are designed to handle a wide range of containers, such as cartons, bags, octabins and drums. They allow these loads to be handled with precision, ensuring safe and efficient handling. These solutions are particularly suitable for palletizing and depalletizing applications in various industrial sectors.

Robots and cobots automate the palletizing of containers, such as boxes, buckets or drums, at the end of the production line. This equipment optimizes the positioning of loads on the pallet, increases the production rate and reduces the physical efforts of operators. In the food industry, they also guarantee compliance with hygiene standards by minimizing human handling.

Palamatic Process's robotic solutions meet the needs of multiple sectors, such as the food industry, chemicals and pharmaceuticals. They are ideal for tasks such as palletizing buckets or boxes at the end of the line, secure transfer of drums or bags and handling octabins. These solutions offer flexibility adapted to varied requirements, including environments requiring a high level of cleanliness or precision.

Each solution offered by Palamatic Process is fully customizable to meet the unique specifications of your industrial process. Our teams of experts support you at every stage, from the analysis of your needs to the complete integration of the system, taking into account your specifications and your performance objectives.

In addition, these solutions offer great flexibility to adapt to varied applications, whether palletizing at the end of the line, the handling of specific containers such as cartons, bags, drums or octabins, or even the implementation of processes requiring rigorous containment. With Palamatic Process, you benefit from technical expertise and innovative technology, designed to optimize your industrial performance.