Case studies - Detergent and laundry powder

Main process steps:

Storage, pneumatic conveying, mechanical conveying, dosing, mixing, packing.

Laundry detergents contain several "agents" that perform a specific function. Industrial production lines ensure the storage, conveying, dosing and incorporation of the different components into the mixing line.

Agents integrating recipes for laundry and detergent products:

- Alkaline compounds (increase the effectiveness of surfactants, borates, carbonates)

- Sequestrant agents (increase the effectiveness of detergents: citrates, metaphosphates, polyphosphates, zeolites, EDTA, NTA, phosphonates)

- Complexing agents (anti-redeposition agents) preventing dirt trapped by surfactants from redepositing on the laundry

- Enzymes degrading organic molecules

- Bleaching agents (perborates, percarbonates, peroxides, sodium perborate, sodium percarbonate, hydrogen peroxide). Their objective is the oxidation of colored molecules.

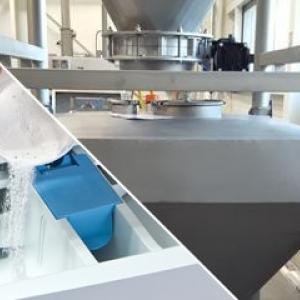

Powder & bulk materials handling solutions:

All these components (powdery and/or liquid) are stored in storage silos or big bags. The formulation and incorporation line includes transfers (generally pneumatic and/or mechanical conveying) allowing loading into the mixer. Intermediate hoppers ensure weighing by weight gain or weight loss. The load cells perform the precise dosing to ensure that the formulation is respected. A line of micro-ingredients completes the detergent production line. After introducing all the bulk materials into the mixer, a spray (incorporation) of perfume in liquid form is performed. For powdered detergents, the industrial mixer is discharged while guaranteeing the granulometric respect of the bulk materials and without segregation.

Nos applications chez nos clients

Optimizing Sensitive Powder Processing with a Custom Solution

Powders Handled: Lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), requiring secure handling due to their toxicity, hygroscopic nature, and...