Palamatic Process has developed bag filling and packaging systems. The range of PalSack® bagging machines, ideal for packaging your powders and bulk products, has been specially designed to meet the requirements of manufacturers in various sectors of activity.

Our filling systems are suitable for all types of bags: burlap, paper, plastic, open mouth bag / open mouth bag, bag with liner, single layer, double layer, microperforated...

Bagging systems for open-mouth bags from the Palsack® range are specially designed for the food, chemical and pharmaceutical industries to fill powdery products, such as milk powders, whey or lactose into open-mouth bags.

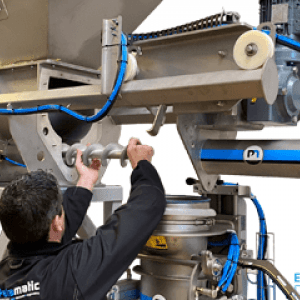

Palamatic Process offers different types of manual, semi-automatic or automatic bag filling stations for bags. Bag fillers can be used for repackaging material into big bags or as a mobile station at the end of the production line. They offer numerous functions: sewing the top of the bag, removing the internal bag, placing crepe paper, sealing the bag with a manual or automatic sealer, etc.

The manual bagger, the semi-automatic or automatic bagger allows you to fill all types of bags ranging from 5 to 50kg. The rate of this type of bagging unit is between 50 and 100 bags/hour. The bag filling station is optimized for processing your powders and bulk products.

Available in steel, 304 L or 316 L stainless steel, the semi-automatic bag bagging machine is an economical and efficient way to fill and handle product bags or bulk bags. This solution is developed for products such as: grains, powders, aggregates, granular products. The system optimizes and facilitates bag change time, significantly increasing the filling rate. The station allows the operator to position the bags easily and quickly, since the four handles are hooked to the front of the system. This bagging unit offers great precision in the dosing of materials, ergonomics of the station, a high rate as well as total confinement.

Several features are possible on the semi-automatic bagging machine:

Palamatic Process has 4 models of bag filling machines depending on the nature of your products and your process requirements:

A Manis® bag handler allowing effortless lifting and handling can be installed on your packaging line to offer the operator maximum working ergonomics. In the same way, a robot ensuring the palletizing of bags at the end of the line can be considered to automate your process.

A wide variety of powders can be processed on this type of bag filling and packaging systems: granules, milk powder, chemicals, food products, lactose, flour, spices, pigments, coffee, animal feed…

In addition to a bag packaging system, Palamatic Process offers pneumatic transport, dosing, mixing, grinding and even powder storage equipment.

Our engineering office has also designed turnkey bag or big bag filling and packaging systems. For example, the TruckFlow® 06 big bag bagging line allows production initially loaded into a bulk truck or tanker to be packaged in a big bag. This packaging line offers a small footprint, a high production rate and is available in an ATEX 20 version.

Palamatic Process bagging stations are compatible with a wide range of bags, including:

Our tailor-made solutions allow the equipment to be adapted to your specifications, guaranteeing optimal efficiency for powdered, granular or powdery products.

Palamatic Process filling stations incorporate advanced technologies to ensure precise and clean filling:

These features reduce dust emissions, ensure compliance with environmental standards, and improve the quality of the working environment.

Yes, Palamatic Process bagging stations are available in versions that comply with NFPA standards for use in explosive areas. These equipment include:

These solutions guarantee safe and reliable bagging for at-risk powders and materials.

Our powder experts offer personalized solutions for your manual or automatic bag filling installations depending on your installation constraints and your flow rates. Together, we define the tailor-made and appropriate solution after visiting your site and following your technical needs. Contact us to come and test your powders in our dedicated testing station.