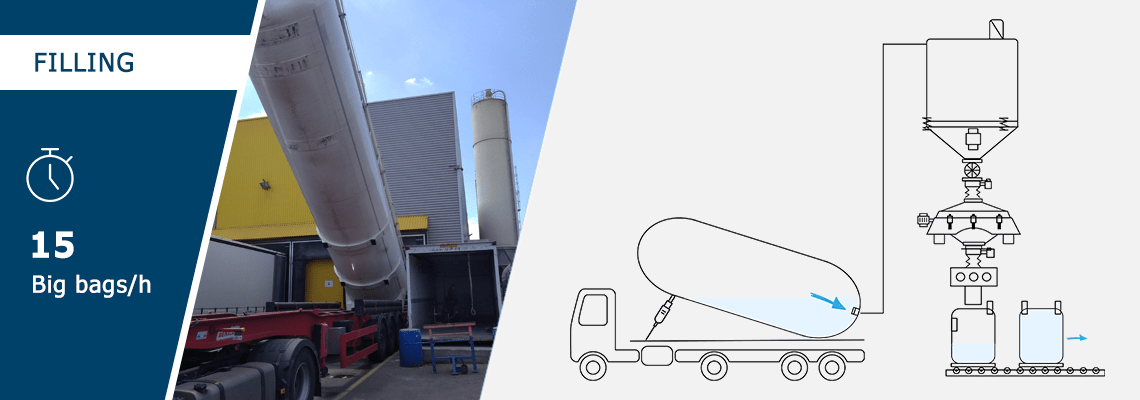

Bulk bag loading line from tanker truck

The TruckFlow® 06 bagging line allows manufacturers' logistics providers to package products initially loaded in bulk trucks and tankers directly into bulk bags.

The simple connection of the truck to the reconditioning line provides the bulk bagging from the tank in 2 hours.

The TruckFlow® 06 reconditioning line is compatible with all types of bulk truck, bulk semi-trailer, pressurized tipper, multi-cell semi-bulk.

- Fully integrated solution for the use of tank trucks

- Small footprint

- High flow rate

- ATEX 20 option available

- Possiblity of an independent compressor to supply the bulk truck tank

Quality Hygiene product

The bulk bag repackaging line is specially dedicated to carriers wishing to offer a repackaging service to their food and/or chemical customers. The reconditioning of the bulk tank is carried out in a metered bulk bag with a certified weight control. The weighing chain integrated into the bulk bag packaging line provides commercial repackaging of the bulk bags.

| TruckFlow® 06 | |

|---|---|

| Rate | 15 bb/h. and emptying a truck in 2h |

| Materials of Construction | Steel, 304L stainless steel, 316L stainless steel |

| Power installed | 68 Kw (with pressurization of the truck tank included / dedicated booster) |

| Compressed air consumption | 3 m³/h @ 6 bars |

| Dedusting flow | 2 500 m³/h |

For silo loading, the driver connects the tank to the loading pipe in order to empty the product into the bulk bag line. A cyclo-filter ensures the reception of the material for continuous supply.

The TruckFlow® 06 line, developed by Palamatic Process, incorporates food safety and quality elements such as a vibrating screener and metal detector in order to provide hygienic repackaging of the bulk material. Due to the integration of this safety device, the bulk packaging line is used to reclassify materials, ensure recycling or provide food packaging services in bulk bags.

When handling explosive products (chemical or food), the ATEX version is selected for use in zone 20-22. Class/Div rated equipment is available for the U.S. market.

Productivity

The operation of the line requires only a line operator and a forklift operator to provide the storage of big bag pallets. Any type of bulk bag can be used on the TruckFlow® 06 line from Palamatic Process.

Choosing a Palamatic TruckFlow® 06 type packaging line guarantees having a single point of contact for the design, manufacture, assembly and delivery of your production equipment. The experience of the Palamatic Process team offers reliability for the final performance of your powder packaging line.

Options for bulk bags

Depending on the industry and the material being processed, a hooding or wrapping machine is installed at the end of the packaging line for preparation of the bulk bags readiness for sale. Loading of the placemat on the pallet is also a possible option on this Palamatic Process packaging line.

Discover the installations of our customers using the bulk bag TruckFlow® 06 bagging line.

All the equipments integrated to the bulk bag bagging process line from a tanker truck are available below.