Description

PalSack®03 bag filling station - containment, precision, high speed, gross weighing

The PalSack®03 bag filler is the fastest filler in the sack filling equipment range.

This packaging machine, fitted with a D14 screw feeder, is designed to provide a high flow rate with high dosing precision. The joint performance of flow rate and precision is made possible by a double metering screw. Each dosing screw has its own motor for rapid control and unitary servicing.

The feeder is fitted with 2 independent screws: a large-diameter screw and a small-diameter screw.

The "large" screw is designed for high flow, filling the first 95% of the bag, while the "small" screw dispenses the last 5%. The small screw thus provides greater dosing precision.

In addition to this double dosing screw technology, an agitator provides agitation of the material for a steady feed of the screws.

This packaging station is designed for manufacturers with requirements on bag filling rates. With the conveying and net weighing hopper options, the bagging rate can reach 200 bags/hour.

The different possible configurations of the PalSack®03 model:

| Ref. | Possible Equipment | Functions | Advantages | |

|---|---|---|---|---|

| Choice 1 | J | Inflatable seal | Dust tight bag connections | Maximum confinement |

| M | Clamping jaws | Quick bag connections | Speed, ergonomic, installation and multi-format bags | |

| Choice 2 | P | Support tray | Tension of the bag during filling | Hygiene, height adjustment for adaptability to multi-format bags |

| C | Motorized roller conveyor | Holding and evacuation of the bag during filling | Ergonomics, increased speed | |

| Choice 3 | Net | Net weighing | Provides accurate amounts of the packaged product | Accelerated rate (dosing in hidden time) / may require a double check weighing system |

| Gross | Gross weighing | Weighing of the entire container and contents | Commercial weighing, traceability |

Our PalSack®03 packaging machine is configurable by modulating the possible basic equipment: choice 1 + choice 2 + choice 3

Example of possible reference: PalSack®03-J-P-Net

-

Rate5

-

Automation4

-

Dosage accuracy5

PalSack®03-J-C-Gross

PalSack®03-M-C-Gross

PalSack®03-J-P-Gross

PalSack®03-M-P-Gross

PalSack®03-J-C-Net

PalSack®03-M-C-Net

PalSack®03-J-P-Net

PalSack®03-M-P-Net

Weighing / accuracy:

In the initial standard version, the weighing loop is installed on the structure of the packaging machine for gross weighing. If your production process requires very high throughput packaging rates, an intermediate weighing hopper can be installed in order to carry out bag replacement operations in masked time.

Dosing accuracy of less than 0.5% is guaranteed by a quick-closing valve and electronic servo control of the dosing motors.

Equipment advantages

- High flow: double screw

- Simple, efficient, multi-format: changing recipes from the integrated touch screen.

- Dosing device adapted to your products: types of screw

- Ease of use: recipe management at the control desk; simplified adjustment of different formats

- High dosing accuracy +/-1%

- Productivity: up to 200 bags/hr

Media

View our equipment in photos

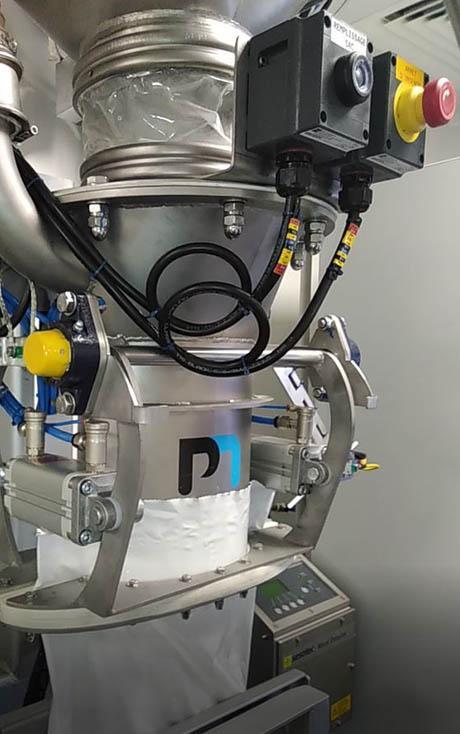

High rate bag filling

The bagging rate can reach 200 bags/hour.

Powder bag sealing machine

The bag packaging line is equipped with a sealing system to ensure the containment of the packaged powder.

Internal view of the double screw feeder

The body of the high flow dosing unit integrates the 2 screw coils and the shaft.

Weighing system on bag filling station

Industrial weighing system on bulk pigment filling line.

Bag filling line with belt conveyor

Conveyor and packaging line for flakes with sealing machine for bag closing.

Commercial weighing on bag filling station

The bag filling machine is equipped with a weighing system that allows the gross weighing of the container.

Sealing the top of the bag after filling

Impulse bag sealer for sealing the bag after the packaging phase.

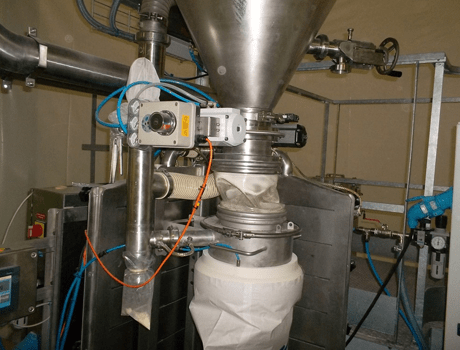

Feeding of the filling head

The bagging machine is fed with flakes via a butterfly valve installed on the buffer hopper.

Double metering screw

Designed to provide a high flow rate with high dosing precision.

Bag packing line with weight control

Conveying and packaging process of flakes in the petrochemical sector.

Automatic bagging machine

The upstream dosing device fills the bag. The volumes are balanced by the double envelope filling tube.

Bagging station for food powders

Bagging of animal meal on an industrial production line.

Bagging of food powder

Sugar bag packaging line equipped with a conveyor belt.

Baking line

Grinding unit for pure powdered sugar with bag packaging.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Processing line for biscuit production factory

Processed powder: Crystal sugar - Line for biscuit factory - Food manufacturer that specializes in biscuits, chocolate and cocoa. The customer's process requirements involved the milling of granulated...Food and Animal Feed

Clean room for packing

Processed powder: milk powder - Clean room for packing - A leading dairy and manufacturer of high value-added milk powder for the leaders in the infant market.Food and Animal Feed

Natural food flavours

Processed powders: apetence factors, natural food flavours - Natural food flavour - The company, which is specialized in the manufacture of flavours for domestic animal feed, was looking to install a...Food and Animal Feed