Description

Flexible fitting - The flexible BFM® fitting connects sealingly the upper and lower pipework section statically and dynamically

-

Ergonomics4

-

Ease of integration4

Connection sleeves for the static and dynamic connection of the upper and lower parts of a pipeline.

The connection sleeves consist of two stainless steel tubes and a flexible coupling. The design allows the flexible sleeve to be easily installed and removed in seconds without the need for tools.

BFM® Fitting: Connecting Upper and Lower Pipeline Sections with a Perfect Static and Dynamic Seal

This flexible BFM® Fitting is designed for tool-free installation and removal in just seconds, ensuring a perfect seal at the connection.

Equipment advantages

- Hygiene : no retention, perfect seal

- Size: perfectly adjustable

- Installation : with no tools, fool-proof system

- Pressure resistance: if an explosion occurs, the gaskets tighten. Assembly for the interior, reinforcing tightening

- Standard sizes : from 100 to 650 mm by 50 mm increments (spare part inventory optimization)

- Safety : flexible fitting change-out with no tools ; simply interlock by hand (one operator)

Media

View our equipment in videos

Manchette de connexion

View our equipment in photos

BFM® fitting sleeve flexible connector

Flexible connection sleeve for filling operation.

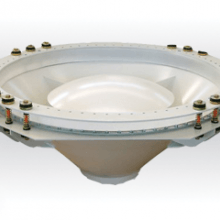

Flexible tank loading sleeve

Flexible sleeve for tank loading.

Industrial process hose fittings

Industrial process hose fittings Palamatic Process

Features

Technical specification

- Hygiene: no retention, perfect seal

- Size: perfect fit

- Installation: without tools, with key system

- Components: isolation of mechanical forces between two parts of the installation

- Pressure resistance: seals close in case of explosion. Mounted from the outside, which strengthens the seal

- Standard dimensions: from 100 to 650 mm in 50 mm increments (optimization of spare parts stock)

- Safety: no tools required to change the flexible sleeve; just push in with your hands (1 operator only)

| Ø Standard internal diameters in mm | Standard lengths (LM) in mm |

|

|

|---|---|---|---|

| 100 | 100 | 150 | |

| 125 | |||

| 150 | |||

| 200 | 200 | ||

| 250 | |||

| 300 | |||

| 350 | |||

| 400 | |||

| 450 | |||

| 500 | |||

| 550 | |||

| 600 | |||

| 650 | |||

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Infant milk powder preparation

Product concerned: infant milk powder - Infant milk powder preparation - Industrial specialized in baby food production - The process consist of conditionning infant milk powder in diverse containing...Food and Animal Feed

Handling of food starch

Processed powders: gluten and starch - Handling of food starch - French company specialized in the conditioning of bulk products and raw materials.Food and Animal Feed

Spice dosing

Processed powder: spice mixture with an apparent density of 500 kg/m³ - Spice dosing - The customer was looking to replace his manual dosing system, in the small-size packaging room, with a weight...Food and Animal Feed

Preparation of milky drink

Processed powders: milk powder and sugar - Preparation of milk drinks - Agribusiness group in the Island of Reunion, this company is a leader in most markets in which it operates: fresh dairy products...Food and Animal Feed

Process of plasterboard production

Processed powder: plaster - Process of plasterboard production - French company producing and selling plaster, products derived from plaster and products based on expanded polystyrene.Minerals and building

Rubber calendering line

Processed powders: 2 references of carbon black (micro pearl) - Rubber calendering line - The facility includes 2 container discharge systems that supply 2 mixing lines with powdered carbon black.Chemical

Masterbatch and additives

Processed powders: cobalt, calcium carbonate CaCo3, titanium dioxide TIO2 - Masterbatch and additives - Discharge of raw materials while maintaining a healthy atmosphere without pollution and without...Chemical

Tanning product

Processed powders: chemical additives - Tanning product - The great diversity of the products and their varied packaging meant that this plant had long been looking for a system that would reduce the...Chemical

Paint formulation

Processed powder: paint powder (polyester resin + fillers + additives + pigments) - Paint formulation - A manual container emptying station feeds a big bag filling system. The container unloading...Chemical

Seeds packing line

Processed products: corn seeds - Seeds packing line - Installation for conditioning corn seeds in big bags. The big bag filling station is supplied upstream via a slide gate valve and a flexible...Chemical

Product refining

Processed powders: ciclopirox, praziqantel - Product refining - French chemical group specialized in pharmaceutical fine chemistry, performance fine chemistry, advanced specialties - new technologies...Fine chemical

Pharmaceutical loading

Processed powder: Sorbitol - Pharmaceutical loading - Manufacturing of basic pharmaceutical products, medicinesFine chemical

Cake mix

Processed powders: modified starch, sodium bicarbonate, fat powder, whipping base, gelatin, milled sugar - Cake mix - Company based in Saudi Arabia that manufactures and distributes dry food materials...Food and Animal Feed

Natural food flavours

Processed powders: apetence factors, natural food flavours - Natural food flavour - The company, which is specialized in the manufacture of flavours for domestic animal feed, was looking to install a...Food and Animal Feed

Animal nutrition food supplements

Processed powders: silica, clay, calcium carbonate, lithothamnium - Animal nutrition food supplements - This customer is a producer of specific mixtures of botanical extracts. In order to ensure its...Food and Animal Feed

Premix manufacturing

Processed powders: silica, wheat, carbonate - Premix manufacturing - The installation consists of a new mixing line for the production of natural additives for animal nutrition.Food and Animal Feed

Powdered veterinary medicinal substance

Processed powder: pharmaceutical powder - Powdered veterinary medicinal substance - The process consists of emptying powders to feed a bagging machine.Fine chemical

Animal flour loading

Powders processed: feather flour, animal flour - Animal flour loading - Palamatic Process has set up a bulk bag packaging station with vibration and automatic releaseof the bulk bag.Food and Animal Feed

Seed conditioning

Processed powder: treated maize seeds - Seed conditioning - This Multinational, an actor on the world seed market, wants a facility located in Brazil for the automatic packaging of corn seeds in big...Chemical

Aromatic herbs conditioning

Processed powder: dried grass seeds - Seeds conditioning - Installation of a double discharge station: big bag emptying and container emptying for mixer feeding as well as a double filling station...Food and Animal Feed

Lime and mineral packing

Processed powders: lime + additives - Lime and minerals packing - The installation involves a FlowMatic® 05 big bag filling station with suspended weighing.Minerals and building

Handling of veterinary bulk solids

Processed bulk solids: veterinary powders - Loading of veterinary powders - Company specialized in animal nutrition and health: workshop for the preparation and mixing of bulk materialFood and Animal Feed

Loading of ingredients for the production of beverage

Processed materials: citric acid, potassium sorbate, sodium benzoate... - Loading of ingredients for the production of beverage - This installation concerns a new production line in a new building of...Food and Animal Feed

Mixing and packing of spices

Processed powders: spice mixtures (curry...), tea and herbal tea blends, fine salt - Spice blending and bagging - Bagging station for packaging spice and powder blends in bags from 1 to 25kg.Food and Animal Feed

Perlite conveying

Processed powder: perlite - Perlite unloading, dosing and conveying - This mineral handling facility consists of an EasyFlow® 125 big bag deconditioning station.Minerals and building

Recycling of milk powder by micronization

Processed powder: dairy product flakes, density 400 to 500 µm - Recycling of milk powder by micronization - The installation consists of the dosing, transfer, grinding and reconditioning of the milled...Food and Animal Feed

Calcium carbonate loading

Processed Materials: calcium carbonate, aluminum oxide, titanium dioxide, silica - Calcium carbonate loading into storage tank - For this project our client company is a specialist in the manufacture...Chemical

Milk powder mixing line

Processed powder: infant milk powder - Milk powder mixing line - The mixing line is totally cleanable with the complete dismantling of the equipment with our Palamatic-EasyClean range of equipment.Food and Animal Feed

Unloading bulk bags containing grains and cereals

Process products: wheat bran, wheat flour, disinsected wheat bran - Unloading bulk bags containing grains and cereals - This bulk bag emptying station aims to feed insects (larvae and adults) with dry...Food and Animal Feed

Entomoculture treatment unit

Treated products: droppings, dead insects, live insects - Treatment unit in the entomoculture - This unit allows the treatment of non-compliant products from the main process.Food and Animal Feed

Spray tower for packaging feed

Processed powders: skim milk powder / whole milk powder. Client in Africa.Food and Animal Feed

Mixing and packing line for dried fruits

The dried fruit recipe preparation line allows you to: - load a paddle mixer with ingredients packaged in boxes - mix the different raw materials according to the recipeFood and Animal Feed

Drum unloading enclosure

Processed product: Triuranium octoxide (U3O8) – Drum tipping station - The installation concerns the installation of a production system that empties, transfers and doses drums of a toxic product...Energy

Bucket filling line

Material: Graphite - Bucket filling line - Turnkey solution for bulk bag emptying, total containment and rapid filling of buckets with graphite powder.Chemical

Cardboard box confined packaging station

Cardboard box confined packaging station - Powder dosing line at dryer outlet for cardboard box packaging feed.Energy

Optimizing Bulk Bag Discharge with BFM® Fitting Connections

Powders Processed: Pharmaceutical excipients and food ingredients - Optimizing Bulk Bag Discharge with BFM® Fitting Connections - Bulk Bag Discharge Solution with BFM® Fitting ConnectionsFood and Animal Feed