Processed powder: silica, clay, calcium carbonate, lithothamnium

Animal nutrition food supplements

Today, the agricultural sector is looking for solutions to reduce the use of antibiotics in order to further protect the health of animals and consumers.

Herbal solutions are booming compared to conventional classical chemical products for animal health.

This customer is a producer of specific mixtures of botanical extracts. In order to ensure its growth, it manufactures phytotherapeutic substances for animal nutrition and therefore equips itself with a mixing and conditioning line at a rate of 5 t/h.

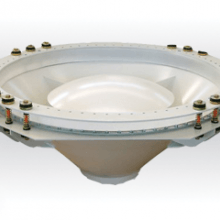

Palamatic Process supplies the equipment for storing and unloading raw materials (stored in silos, big bags or sacks), the solutions for conveying and dosing the materials.

Installation and commissioning are also carried out by Palamatic Process.