Description

IBC Container filling station - Manual or automatic

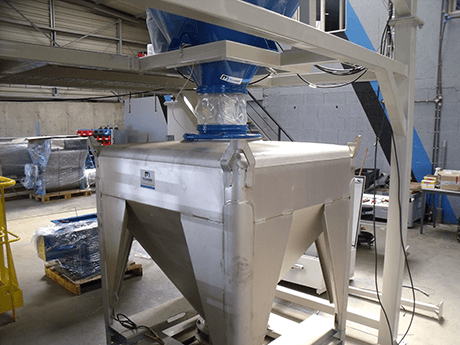

IBC Container filling station IbcFill® 01 with dust-tight connection. Our IBC container filling stations allow a contained conveying of bulk products. In the automatic version, the installation and removal of the connection plate is carried out without the intervention of the operator.

The automatic filling of Palamatic Process industrial IBC containers reduces the level of exposure of the operator to potentially dangerous bulk materials. This automated system has been designed to provide a high standard for hygiene, safety, ease of cleaning and maintenance.

-

Containment5

-

Automation5

Equipment advantages

- Balancing during filling and dedusting

- Sealing by inflatable seal guaranteeing the absence of dust emission

- Automatic docking (optional)

- Ergonomic steering box

Media

View our equipment in videos

Industrial container filling head IbcFill® 01

Container filling station IbcFlow® 01

This steel-stainless/steel container is suitable for storing your powders and bulk materials, standard or custom models.

View our equipment in photos

IBC FILL - Container filling

For a safe and hygienic filling of industrial container.

Steel - stainless steel container

The filling head of the station is provided with a tight connection.

Container filling station

The IBC Containers® filling head is used to connect a manual bag dump station to a container in a completely sealed way to carry out a gravity flow of your raw ingredients and bulk materials.

Industrial containers filling

- Balancing during container filling and dust collection

- Sealing by inflatable seal ensuring no dust emission

Stainless steel bulk container filling Palamatic Process

Sealing of the connection to prevent the emission of dust and loss of bulk materials.

Container filling system

Filling system for stainless steel containers. Containment and safety during conditioning.

Container filling line

Powdered raw materials are generally delivered in sacks, big bags or bulk within the production sites. Palamatic Process offers container filling stations for the storage of all types of powders: sugar, cocoa, starch, spices, dextrose...

Container filling with flexible fitting

Storage of carbon black from a big bag emptying station. A tubular conveying screw transports the powder into the stainless steel container.

Industrial bulk container

Anti-static telescopic tube with FDA metal spirals.

Container filling with flexible fitting

Anti-static telescopic tube with FDA metal spirals. Sealing of the connection to maintain a healthy, dust-free working environment.

Steel - stainless steel container filling

Stainless steel container for storing cake mix.

The bulk ingredients are deconditioned in an automatic discharging station Minislit® and then carried in the container.

Industrial container filling IbcFill® 01

Automatic filling of the stainless steel container. The fattened milk powder is introduced in a contained way through a telescopic tube.

Steel - stainless steel container filling

Slope at 62° to facilitate the flow of bulk materials during emptying.

Container filling system

Flexible sleeve to avoid dust emissions in the operators' working environment.

Dust-tight container filling

Airtight packing of fattened milk powder.

Container filling line

Automatic filling of the stainless steel container. The fattened milk powder is introduced in a contained way through a telescopic tube.

IbcFill® - Container filling system

The operator lifts the bag using the bag manipulator: the bag is positioned on the bag dump station. The powder is hygienically conveyed into the container.

Stainless steel storage container

The storage container is supplied with powder through a flexible connection sleeve.

Steel industrial storage

Storage container on roller conveyor.

Container packaging

Packing of iron oxide and hydroxide for the production of red and black paint.

Station de remplissage de conteneurs industriels de stockage

The industrial container is fed thanks to a vibratory sifter.

Features

Technical specification

| Racing | 1,500 mm |

|---|---|

| Technology | Pneumatic cylinder |

| Containment | Inflatable seal, pressure plate |

The IBC Containers® filling head allows a hopper to be completely sealed to a container for a gravitary transfer of your materials.

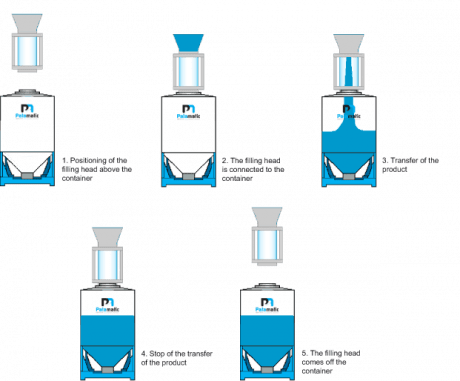

The filling head is manually positioned or automatically lowered on the inlet port of the container by two pneumatic cylinders. The flexible connection unfolds and the head reaches the container. This filling head is composed of a inflatable seal that expands outward to firmly seal the lid and thus prevent any dust leakage during the filling process.

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Spice production

Processed powder: paprika - Spice production - Industrial company specialized in the treatment of food additives. The purpose of the installation is to sieve the paprika powder for repacking into...Food and Animal Feed

Animal nutrition food supplements

Processed powders: silica, clay, calcium carbonate, lithothamnium - Animal nutrition food supplements - This customer is a producer of specific mixtures of botanical extracts. In order to ensure its...Food and Animal Feed

Premix manufacturing

Processed powders: silica, wheat, carbonate - Premix manufacturing - The installation consists of a new mixing line for the production of natural additives for animal nutrition.Food and Animal Feed

Handling of veterinary bulk solids

Processed bulk solids: veterinary powders - Loading of veterinary powders - Company specialized in animal nutrition and health: workshop for the preparation and mixing of bulk materialFood and Animal Feed

Loading of ingredients for the production of beverage

Processed materials: citric acid, potassium sorbate, sodium benzoate... - Loading of ingredients for the production of beverage - This installation concerns a new production line in a new building of...Food and Animal Feed