Powder processed: paprika

Spice production

Industrial company specialized in the treatment of food additives.

The purpose of the installation is to sieve the paprika powder for repacking into Palamatic Process industrial containers.

Container dumping station

The filled industrial container is placed on the upper part of the container dumping station with an electric hoist. It is fitted with a conical discharge valve to ensure a controlled dosage to feed the centrifugal sieve.

The IbcFlow®01 Container discharger is provided with a pneumatic actuator (cylinder) to ensure the opening and closing of the storage container. The installation, in the pneumatic control cabinet, of a flow regulator allows the opening and/or closing speed to be easily managed.

The cylinder is supplied with electromagnetic sensors to ensure that the valve is correctly positioned in the axis of the centrifugal screen connection. Once in position, the action on the pneumatic cylinder ensures that the valve is opened by a mechanical system.

At the outlet of the butterfly valve, a seal fastened to the structure ensures a sealed connection.

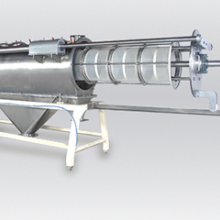

The measured powder is fed into the cylindrical screen via a feeding screw that is integrated into the centrifugal screen.

Sifting

The powder is projected through the grid of the centrifugal sieve, destroying clods and agglomerates.

The paprika powder is inserted into the centrifugal sieve chamber where it is spun by the rotating blades. The rotor blades break up small agglomerates and fluidize the spice. The centrifugal force propels the fine particles through the centrifugal screen while the waste and coarse grains are dumped at the outlet of the industrial screening machine. The centrifugal screen ensures a clean bulk material, without clods, without foreign bodies and protects your production line from possible mechanical damage. It guarantees a high quality final product.

IbcFill®01 container filling system

The empty container ready to be filled is positioned on the lower level, on the lower part of the station.

The IBC Containers® filling head allows the centrifugal screen to be connected to the polyethylene container in a completely sealed manner to carry out the gravitational transfer of the paprika in a confined manner.

The filling head is automatically lowered to the inlet opening of the storage container by two pneumatic cylinders. The flexible connector extends and the nozzle docks the container. This filling head consists of a inflatable seal that expands outward to firmly seal the lid and prevent product leakage during the filling process.

All surfaces in contact with paprika are made of appropriate materials and are maintained to prevent contamination of the spices.

These polyethylene transport containers made of plastic are rotomoulded and are ideal for the food industry. They offer a 60° flow cone.

These industrial polyethylene containers are provided with a traceability marking in the form of a logo and indications include the date of manufacture of the container, the final assembly date and the article number.