Description

Drop-through rotary airlock valve - Extraction and feeding of bulk materials

4 models: rate from 2.2 to 19.5 liters/rev.

Cast iron or stainless steel manufacturing

Rotary airlock valves are designed for bulk material extraction and dosing operations.

Rotary airlock valves are used for the dosing, feeding or discharging of fine-grained and powdered materials or granulates contained in silos, hoppers, pneumatic conveying installations, filters or even cyclones.

Exploded view:

Equipment advantages

- Compact and robust design

- Easy access to internal mechanical parts for a quick and simple cleaning

- ATEX version

- High feeding accuracy

Media

View our equipment in photos

Dosing rotary airlock

Cast iron or stainless steel body.

Rotary valve under hopper

The drop-through rotary airlock valve feeds and discharges your bulk materials and raw ingredients in a controlled way.

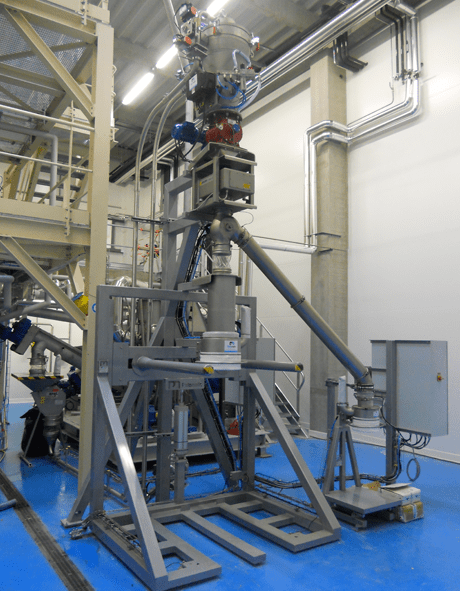

Drop through rotary valve on industrial production line

The primary function of a rotary valve is to regulate the flow of the bulk material between two vessels while maintaining a good airtightness.

Hopper fitted with a rotary valve

Storage and conveying for dissolution of sugar in a weighed cast iron tank.

The processed bulk materials, here beet sugar and cane sugar, are vacuumed into a continuous discharge cyclone via a rotary lock to the dissolution tank.

Easy access to the mechanical parts

Easy access to internal mechanical parts for easy cleaning.

Rotary airlock on pneumatic conveying

For extraction and dosing the bulk material at the outlet of the cyclone.

Pneumatic conveying feeding

The rotary valve is used for the continuous depacking of bulk solids and raw ingredients from silos, hoppers, pneumatic conveying systems, filters and cyclones.

Drop through airlock rotary valve

Gearmotor on a drop through airlock rotary valve.

Palamatic Process rotary valve

Effective for the treatment of all types of powders: cocoa, sugar, flour, granules...

Rotary valve for dust collection

The rotary dust collector is suitable for simple and not very demanding industrial applications, where its main function is that of an airlock.

Rotary valve for pneumatic conveying applications

The ERI 200² rotary airlock valve for continuous discharge into the mixing tank.

Mise en big bag

Integrated equipment:

- FlowMatic® 03 - station de remplissage big bag

- Clamping ring

Dosing rotary valve

ATEX version for explosion and flame resistance.

Rotary valve for food powders

Airlock valve for maltodextrin dosing.

Dosing and conveying rotary valve

Rotary airlock valve on maltodextrin discharge and conveying line.

Rotary lock under cyclone separator

Discharge of maltodextrin bags and their transfer to a mixing tank.

Rotary valve under hopper

Food additive dosing line with cleaning in place of all equipment.

Rotary valve under big bag discharging station

Feeding of a dissolution tank for atomization on a drying tower.

ATEX rotary valve for milk powder handling

The rotary valve allows the extraction at the outlet of the vibrating conveyor and the dosing of the milk powder into the hopper

Drop through rotary airlock

The airlock is positioned under a big bag emptying station for silica handling.

Pneumatic line with integrated dosing

Mixing and feeding line for raw materials for cementing.

Rotary valve for bulk materials handling

The rotary valves are designed for continuous feeding and pressure tightness between the upstream and the downstream process.

Powder handling - Rotary valve

From 2.2 litres/rev. to 19.5 litres/rev.

Features

Technical specification

4 models: 150², 200², 250², 300²

The drop through rotary airlock valves are designed to feed and discharge in a controlled way powders and bulk materials coming from silos, hoppers, pneumatic conveying installations, bag filters houses, cyclones. This rotary airlock valve is suitable when a high throughput is required. The effective flow rates are very variable depending on the materials flowing.

Technical specifications:

| Modèles | 150² | 200² | 250² | 300² |

|---|---|---|---|---|

| Volume per revolution (liters) | 2.2 | 5.4 | 10.9 | 19.5 |

| Flange section in mm | 150*150 | 200*200 | 250*250 | 250*250 |

Variable filling coefficient depending on the material being conveyed and the speed of rotation:

| Manufacturing materials | Cast iron or stainless steel |

|---|---|

| Rotor surface treatment | Nickel plating, tefloning, hardened paddles |

| Motorization | Direct or chain sprocket |

| Rotor | Steel or stainless steel |

| Rotor set speed | 10, 20, 30 rev./min. |

| Variable speed of the rotor | 4-35 rev./min. |

| Capacity | 2.2 to 19.5 liters/rev. |

Example of implementation:

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Preparation of milky drink

Processed powders: milk powder and sugar - Preparation of milk drinks - Agribusiness group in the Island of Reunion, this company is a leader in most markets in which it operates: fresh dairy products...Food and Animal Feed

Icing sugar line

Processed powder: starch and granulated sugar - Icing sugar line - French sugar cooperative company - Supply and commissioning of a set of machines for the production of icing sugar and starch to feed...Food and Animal Feed

Paint formulation

Processed powder: paint powder (polyester resin + fillers + additives + pigments) - Paint formulation - A manual container emptying station feeds a big bag filling system. The container unloading...Chemical

Cake mix

Processed powders: modified starch, sodium bicarbonate, fat powder, whipping base, gelatin, milled sugar - Cake mix - Company based in Saudi Arabia that manufactures and distributes dry food materials...Food and Animal Feed

Animal nutrition food supplements

Processed powders: silica, clay, calcium carbonate, lithothamnium - Animal nutrition food supplements - This customer is a producer of specific mixtures of botanical extracts. In order to ensure its...Food and Animal Feed

Premix manufacturing

Processed powders: silica, wheat, carbonate - Premix manufacturing - The installation consists of a new mixing line for the production of natural additives for animal nutrition.Food and Animal Feed

Blower for feeding containers

Processed materials: crushed egg shells - Blower for feeding containers - The purpose of the equipment is to collect crushed egg shells from a centrifuge / crusher placed downstream of automatic...Food and Animal Feed

Refined sugar conveying

Processed material: refined sugar - Refined sugar conveying - On-site installation of repackaging equipment for the transfer of sugar stored in shipping containers with an inner liner to a bulk bag...Food and Animal Feed

Refiom processing line

Processed products: fly ashes and ash embers - Refiom processing line - Big bag filling in thermal power plant in a household waste incineration plant.Energy

Premix compound packing

Treated powder: premix compound - Premix compound packing - Our customer, a specialist in PVC compounds and polymer composite materials, required the packing of its finished product - polymer...Chemical

Milk powder mixing line

Processed powder: infant milk powder - Milk powder mixing line - The mixing line is totally cleanable with the complete dismantling of the equipment with our Palamatic-EasyClean range of equipment.Food and Animal Feed

Sugar grinding unit

Processed powders: icing sugar from white granulated sugar and starch - Sugar milling unit - The installation consists of feeding the mill with granulated sugar and then packaging the resulting icing...Food and Animal Feed

Unloading bulk bags containing grains and cereals

Process products: wheat bran, wheat flour, disinsected wheat bran - Unloading bulk bags containing grains and cereals - This bulk bag emptying station aims to feed insects (larvae and adults) with dry...Food and Animal Feed

Insect breeding unit

Processed products: bran, meal, droppings, live insects, dead insects - Insect breeding unit - This workshop is the heart of the insect breeding process.Food and Animal Feed

Grinding and packaging of finished products

Processed products: dried insects - Grinding and packaging of finished products - Workshop for processing and packaging products for the animal nutrition sector.Food and Animal Feed

Manufacturing line for petfood industry

Processed Powders: Soy Flour, Brewer Yeast, Corn Starch, Dried Whey... - Manufacturing line for petfood industry - Manufacturering of dry and liquid flavor enhancers for the pet food industryFood and Animal Feed

Cement unloading and conveying

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton bulk bags with pneumatic transfer of material to silo storageMinerals and building

Confined deconditioning, dosing and transfer of powders

Processed powders: Minerals and additives (such as titanium dioxide) for the manufacture of paints - Emptying of big bags into mobile IBCs with dosing and transfer of the product to a mixer downstream...Chemical

Process for mixing dry ingredients

Processed Materials: Granulated Sugar, Rebaudioside M, Cocoa Powder and various minor ingredients - Process for mixing dry ingredients - The new facility expansion project required the capabilities of...Food and Animal Feed

Bucket filling line

Material: Graphite - Bucket filling line - Turnkey solution for bulk bag emptying, total containment and rapid filling of buckets with graphite powder.Chemical