Description

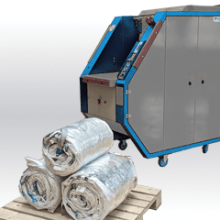

The SackBot 130 for sack emptying delivers precision, cleanliness, and safety to boost your productivity.

The SackBot range, including models 110, 120, and 130, is designed to meet the modern challenges of sack handling and emptying in the most demanding industrial environments.

Whether managing fine powders, granular products, or complex materials, SackBot robots excel in precision, efficiency, and seamless integration into various production lines.

From processing plastic granules to handling fine and challenging powders, each model provides a tailored solution to meet specific industrial needs. These solutions improve productivity, reduce risks to operators, and ensure optimal continuity of production flows.

-

Automation5

-

Hygiene5

-

Rate4

SackBot 130: A Robotic Solution for Industrial Performance

A Comprehensive Range of Robots for Diverse Needs

The SackBot 130 is the most advanced model in the range.

It is engineered to handle the most complex powders and a variety of sack types (except woven sacks). This robot features cutting and emptying technology that guarantees consistent and flawless results.

With its cross-positioned mobile blades and precise gripping system, the SackBot 130 can handle a wide variety of powders, including those with hygroscopic or compact properties.

Robotic Advantages That Transform Your Industrial Processes

- Enhanced Operational Efficiency: With a throughput of 1 to 2 sacks per minute and residue-free cutting, the SackBot 130 optimizes the flow of raw materials, ensuring uninterrupted and smooth production.

- Impeccable Hygiene: Its stainless steel construction fully complies with food and pharmaceutical standards, reducing the risk of contamination.

- Risk Reduction: By minimizing manual handling, SackBot robots reduce hazards for operators while increasing productivity.

Gripping Systems Variants

| Variant | Pallet Detection Method | Robot Translation Possible | Ideal Applications |

|---|---|---|---|

| A | Palletization plan | No | Stable configurations |

| B | Camera | No | Precise repositioning |

| C | Palletization plan | Yes | Expanded fixed zones |

| D | Camera | Yes | Complex environments |

Example: Variant D, combining a camera for sack detection with a translation system, is ideal for dynamic environments with variably positioned pallets.

Customer Benefits with the SackBot 130

Reduction in Operational Costs

By automating repetitive manual tasks, the SackBot 130 minimizes risks of human errors and accidents, significantly reducing maintenance and safety costs while boosting overall profitability.

A Flexible Solution for Complex Environments

The SackBot 130 can handle a wide variety of sacks and powders, including those with challenging properties such as high hygroscopicity or a tendency to clump. This versatility ensures easy adaptation to your needs, regardless of your industry.

Protected Operators and Regulatory Compliance

The food, chemical, and pharmaceutical industries enforce stringent hygiene and safety standards. With integrated dust removal systems and a hygienic design, the SackBot 130 ensures a clean, safe working environment that complies with international regulations.

Increased Productivity

With the SackBot 130, your teams can process a wide variety of sacks and powders without interruption. This efficiency translates into reduced downtime and significantly higher production rates.

Guaranteed Compliance and Hygiene

SackBot robots meet the strictest hygiene and industrial safety requirements. Whether for food, pharmaceutical, or chemical products, their design ensures complete powder containment and reduced dust emissions.

Features

Technical Details and Applications

| Modèle | SackBot 100 | SackBot 120 | SackBot 130 |

|---|---|---|---|

| Product Types | Plastic granules, sand, frozen IQF products | Seeds, grains, kernels | All types of powders, including challenging ones (carbonate, flour) |

| Sack Types | Single-layer plastic sacks | Woven sacks and single-layer paper sacks | All types except woven sacks |

| Theoretical Throughput | 2 sacks/min. | 3 sacks/min. | 1 to 2 sacks/min. |

| Gripping Head | Suction cup with safety claws | Claws | Suction cup with safety claws |

| Sack Opening Tool | Fixed cross blades | Fixed or rotary blade (disc); sack slides over a plate and blade | Mobile cross blades operated by guiding units |

| Advantages | Easy cleaning with a fixed system | - Easy cleaning - Easy blade removal - Clean and precise cuts |

- Efficient cutting for all sack types |

| Disadvantages | Does not accept all sack types | Does not accept all sack types | Lower throughput compared to other models |

Primary Applications for SackBot 130

- Food Industry: Hygienic emptying of flours, powders, and sensitive granular products.

- Chemical Industry: Handling hygroscopic and corrosive materials.

- Pharmaceutical Industry: Meeting sterility standards for medical powders.

Technical Features of SackBot 130

- Gripping Head: Suction cup with safety claws for reliable sack handling.

- Cutting Tool: Mobile cross blades operated by guiding units for clean, residue-free cuts.

- Design: Stainless steel structure, ideal for applications requiring impeccable hygiene.

Characteristics of Gripping Systems

| Gripping System |

|

Ideal Applications |

|---|---|---|

| A |

- Utilizes predefined palletization plans |

Stable configurations with fixed pallet positions. |

| B | Same principle as System A, with an added slide to extend reach. | Dynamic environments requiring greater flexibility. |

| C | Integrated vision system for precise sack detection and localization on pallets. | Ideal for environments where sack positions vary. |

| D | Combines a vision system with a slide for maximum flexibility and reach. | Large-scale, high-variability operations. |

Descriptions of Gripping Systems

- System A: Simple and Reliable Management

This system relies on predefined palletization plans, enabling the robot to operate without a vision system. Its range allows it to manage up to three different pallets, making it ideal for environments with fixed and stable pallet positions.

- System B: Extended Reach with a Slide

System B enhances System A by adding a slide that increases the robot's reach. This makes it suitable for handling a larger number of pallets, ideal for environments requiring more flexibility and dynamism.

- System C: Precision with Vision

Equipped with an integrated vision system, System C detects and precisely locates sacks on pallets, regardless of their arrangement. This technology minimizes gripping errors, optimizes productivity, and ensures efficient handling.

- System D: Maximum Flexibility and Precision

System D combines the advantages of Systems B and C by incorporating a slide with a vision system. This dual capability makes it the optimal solution for complex, large-scale operations requiring maximum flexibility.

Why Choose Palamatic Process for Your SackBot Robots?

Recognized Technical Expertise

At Palamatic Process, we understand the unique challenges of modern industries. That’s why we design custom equipment, like the SackBot range, to meet the highest standards of safety, efficiency, and regulatory compliance.

Tailored Solutions for Every Client

Collaborating with our experts ensures a thorough analysis of your needs, guaranteeing seamless integration of the SackBot 130 into your production line. Our robots enhance productivity while maintaining impeccable quality standards.

Comprehensive and Continuous Support

From feasibility studies to post-installation maintenance, our team is dedicated to maximizing the performance of your equipment. This commitment ensures a quick return on investment and long-term satisfaction.