Description

Octabins OC2 filling station - High speed packaging in gross or net weight

The FlowMatic® Octabin OC2 filling station enables high rate packaging in gross weighing.

This equipment allows high performance and ergonomics of the station through an optimization of the filling rate of your octabins. This packaging line allows the net weighing of large volumes ready for sale.

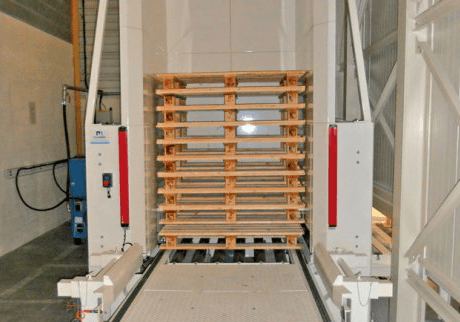

The High speed FlowMatic® OC2 Octabin model is designed to optimize the filling rate of your octabins. The pallet unstacker, associated with the conveyor line and the weighing system, allows the packaging of large volumes ready for sale. The access platform and the overall ergonomics of the workstation simplify and streamline operator interventions. Octabin OC2 filling station allows high speed packaging in gross weighing.

-

Automation4

-

Rate4

-

Overall dimensions2

Equipment advantages

- Vibrating table

- Handling conveyor

- Dosing and weighing

- Pallet unstacker

Media

View our equipment in videos

Mat laying on pallet

Ligne de production industrielle avec chargement d'octabins.

View our equipment in photos

Octabin filling system - OC2

The station ensures a high rate filling of octabins.

Octabin filling system - OC1

Octabin conditioning station on an industrial glue production process line.

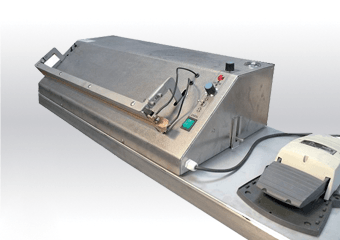

Load cells

Weighing system on an octabin filling station on a premix mixing and packaging line in the food industry.

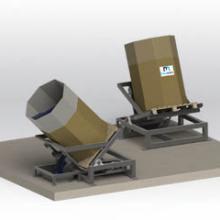

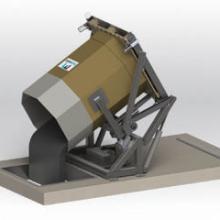

Pallet unstacker

Pallet unstacker on octabin conditioning line on industrial powder conditioning process.

Octabin filling system - OC1

Octabin packaging of white sugar and crystal sugar.

Chargement octabin

Chargement d'octabins avec des billes de polystyrène à partir de sacs et de big bags.

Convoyeur à rouleaux sur ligne de conditionnement d'octabins

Ligne de transfert et de conditionnement d'octabins dans le secteur de la chimie.

Remplissage octabin avec sache interne

Ligne industrielle de conditionnement de billes de polyéthylène en octabins.

Ligne complète de chargement d'octabins

Ligne industrielle de convoyage et de conditionnement en octabins.

Features

Technical specification

| Rate | 20 to 40 octabins/h |

|---|---|

| Capacity | 2 tonnes/big bag |

| Matériaux de fabrication | Acier peint, inox 304L, inox 316L |

| Puissance installée | 10,9 kW |

| Consommation air comprimé | 1.1 Nm³/h |

| Débit de dépoussiérage | 300 m³/h |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 1.0 kW

Operating pressure: 6 bar

Input 4 - 20 mA: 1

Digital input: 10

Digital output: 15

Accuracy of the weighing chain: +/- 500 grams

Dimensions maximum octabins length * width * height: 1,200 * 1,200 * 2,400

Integrated equipment :

- Access platform

- Roller conveyor

- Vibrating densification table

- Internal pocket shaping fan

- Filling head with assembly plate

- Automatic pallet unstacker