Description

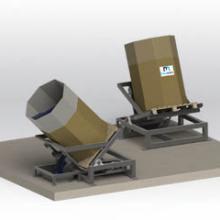

Octabin unloading - Octabin Tipper - Octoflow 02:

For all types of octabins

Integrated equipment:

Pneumatic clamping with tilting by hydraulic unit.

-

Rate3

-

Automation3

Equipment advantages

- Pneumatic clamping

- Hydraulic unit tilting

Media

View our equipment in photos

OctoFlow® 02

Octabin dumper in industrial production lines involving raw ingredients and bulk materials handling.

Octabin

Octabin dumper in industrial production lines involving bulk solid materials.

Octabins

Bulk solids storage in octabins.

Features

Technical specification

| Rate | 1.5 tons/octabin |

|---|---|

| Manufacturing materials | Painted steel, 304L stainless steel, 316L stainless steel |

| Installed power | 16.3kW |

| Compressed air consumption | 0.6m³/h |

| Tilting angle | 0 to 120 |

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Average power consumption | 4,1 kW |

| Input 4-20 mA | 6 bars |

| TOR input | 13 |

| TOR output | 24 |

| Accuracy of the weighing chain | ± 500 grams |

| Dust removal rate | 300 m³/h. |

| Maximum size of octabins (Length x Width x Height) | 1,200 x 1,200 x 2,400 mm |

Operation procedure:

- Loading of empty octabins to the lift truck

- Automatic decapping

- Transfer of octabins

- Automatic filling

- Manual closing

- Automatic wrapping

- Extraction of full octabins with a forklift

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Tanker truck loading

Processed product: plastic granules - Tanker truck loading - Container tipping equipment for the transfer of plastic granules into a tanker truckChemical