Améliorer les pratiques de travail afin de les rendre plus sûres et réduire les risques de blessures des opérateurs dues à des ports de charges lourdes répétitifs.

Les opérateurs travaillant sur les lignes de production sont souvent confrontés à la tâche quotidienne de soulever et de charger de lourds sacs de matériaux secs. Même lorsque des techniques de levage appropriées sont utilisées, la tension quotidienne liée au port des sacs de poudres peut faire des dégâts sur le corps humain au fil du temps.

En effet, les opérations de levage répétitives et lourdes peuvent parfois entraîner des blessures au niveau du cou, des épaules et du bas du dos. La gravité de ces blessures peut aller de simples foulures à de graves déchirures qui nécessitent des semaines, voire des mois de rééducation.

Le déchargement et le port manuels de sacs d’ingrédients ou de solides en vrac sont des pratiques courantes dans les process de production. Les sacs de poudre peuvent varier en poids, mais pèsent généralement entre 25 et 50 kg.

La dépalettisation manuelle hebdomadaire d’une palette sacs peut finir par provoquer des blessures chez les opérateurs. Les lignes de fabrication doivent donc être adaptées et appliquer toutes les mesures possibles pour protéger leur personnel et minimiser tous les risques de blessure.

1. Prepare

Before you lift, think and plan out how it should be done:

- How heavy/awkward is the bag? Should I use mechanical means (e.g., a hand truck or sack vacuum lifter) or another person to help me with this lift?

- Where do I need to place the bag (e.g., bag dump station or sack tip tray)? Is the path clear of obstructions, stairs, and other interference?

- Do I need gloves or other personal protective equipment? Should another person help me with the bag or sack?

2. Lift

Stand close to the bag and keep your elbows and arms close to your body. Keep your back straight while lifting and bend at the knees. Try keeping the bag close and centered in front of you while looking up and ahead. Get a firm grip established and do not twist while lifting. Do not make fast or sudden movements; use a smooth motion while lifting. If the load is too heavy, find someone to help you with the lift.

Do you need personal advice on sack lifting units?

I am at your disposal.

Loïc, powder expert

3. Carry

Do not twist your body; instead, pivot your feet in order to turn. Your hips, shoulders, toes, and knees should all face the same direction. Keep the load close to your body with your elbows close to your sides. If you get tired, set the bag down and rest for a few minutes. Don’t let yourself get so tired that you cannot properly set down or lift the bag or sack.

4. Release

Lower and place the bulk material bag down the same way you picked it up, just in reverse order. Bend with the knees, not with the hips. Keep your head up and do not twist your body. Keep the bag as close to the body as possible. Wait until the bag is secure to release your hold.

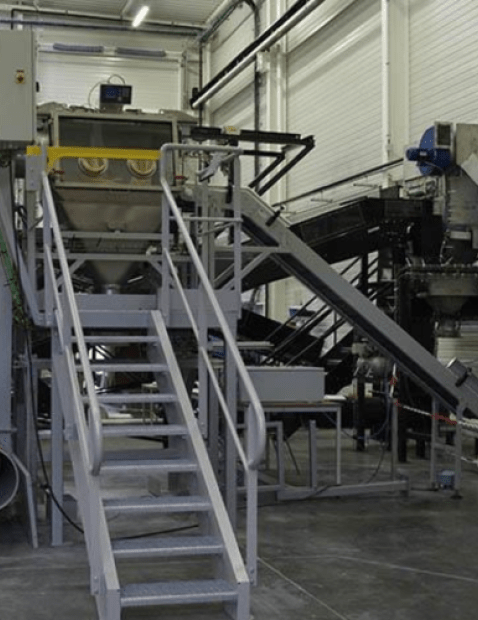

The Palamatic Process Solution – Reduce the Risk of Lifting Injuries

Our staff has extensive experience in bulk material handling solutions. One such solution is our Sack Manipulator Manis 160-1700. This bulk material handling equipment offers superior sack lifting capabilities with minimal worker effort. Operating off the principal of vacuum suction, the boot of the bag lifter can easily and gently adhere itself to paper, plastic and poly-woven sacks up to 175 lbs in weight. The vacuum lifter setup is rather simple and easy to use. A vacuum pump is connected to a hose mounted to a jib crane. At the end of the crane is an extendable and retractable lifting hose. A suction boot with simple controls completes the bulk handling systems and allows the operator to control the intensity of the vacuum for lifting and lowering the packages.

The vacuum sack handler can be modified to work best in your process line.

Examples of installations include:

- Rotating post on a mounted jib crane

- Inverted rotating post on jib crane (lower height requirements)

- Mounting for support structures (ceiling or support beams)

- Fixed columns to support lift equipment over a larger area

- Telescoping beams to reach areas with limited access

Vacuum lifting systems are designed to make repetitive lifting of heavy loads easy and ergonomic, eliminating strain and muscle fatigue. The lift and lower controls are simple enough to use with one hand, and almost all the weight of the load is carried by the suction of the vacuum pump. Industrial manipulators are easy to use, install and can prevent operator strain and injury with a minimal investment.

Since 1992, Palamatic Process has provided bulk process equipment to over 2000+ installations in more 30 countries. We offer knowledge and expertise in all manner of powder handling solutions.