- 1. What is a collaborative robot?

- 2. Differences between cobots and traditional robots

- 3. How cobots work and their unique technologies

- 4. Why integrate cobots into your production lines?

- 5. Palamatic Process solutions featuring cobots

- 6. Industrial applications where cobots make a difference

- 7. Pricing and return on investment (ROI)

- 8. Future trends in industrial cobotics

Cobots, or collaborative robots, represent a major advancement in the field of collaborative robotics. Unlike traditional industrial robots, these machines are designed to work closely with human operators without physical barriers.

With their integrated sensors and advanced safety systems, cobots ensure safe and productive interaction with their environment. This new approach to automation paves the way for more flexible, accessible, and efficient solutions tailored to the challenges of Industry 4.0.

What is a collaborative robot?

A collaborative robot, or cobot, is a type of industrial robot designed to work safely alongside humans without requiring physical separation, such as cages or barriers. Unlike conventional industrial robots, cobots are equipped with advanced safety and adaptability features, making them highly versatile and intuitive.

The origin and evolution of cobots

The concept of collaborative robotics emerged in the 1990s with the idea of complementing human skills rather than replacing them. This vision led to the development of robots capable of meeting diverse industrial needs while adhering to strict safety standards.

FANUC, for example, pioneered this approach. Today, cobots are used across numerous industries, from automotive assembly lines to pharmaceutical laboratories and the food sector.

Differences between cobots and traditional robots

| Features | Cobots | Traditional robots |

|---|---|---|

| Work environment | Share workspace with humans | Require secured zones (e.g., cages) |

| Installation | Simple, quick, and cost-effective | Complex and costly |

| Programming | Accessible to non-expert operators | Requires automation expertise |

| Flexibility | Versatile, suited to varied tasks | Dedicated to fixed tasks |

| Safety | Detection systems to avoid collisions | Limited or no collaborative features |

Example

In a production line, a traditional robot might be used solely for packaging, whereas a cobot can handle packaging, quality control, and even sorting assistance at the same station.

Do you have a cobot implementation project?

I'm available to advise and support you in your study.

Loïc, cobot expert.

How cobots work and their unique technologies

Cobots stand out due to their advanced technological architecture, combining safety, flexibility, and performance.

Detection and safety systems

Cobots are equipped with sophisticated sensors, such as 3D cameras, LIDARs, or force sensors. These devices detect operator movements and adjust behavior in real time. For instance, if a cobot detects a human presence too close, it will slow down or stop automatically to prevent any collision risks.

Intuitive programming

Thanks to simplified user interfaces (often based on drag-and-drop), cobots can be programmed by non-specialist operators. This accessibility reduces integration costs and speeds up commissioning.

Mechanical flexibility

The articulated arms of cobots mimic human movements, enabling them to perform complex tasks with high precision.

Communication and connectivity

Cobots are compatible with the main industrial protocols like OPC-UA, facilitating their integration into existing production chains.

Why integrate cobots into your production lines?

Integrating cobots offers several strategic advantages:

- Reduced costs: Cobots are often less expensive than traditional robots, with lower maintenance needs.

- Increased safety: Integrated sensors reduce accidents in industrial environments.

- Operational flexibility: Adaptable to rapid production changes, cobots offer unparalleled versatility.

- Enhanced productivity: By taking on repetitive tasks, cobots free up operators for higher-value activities.

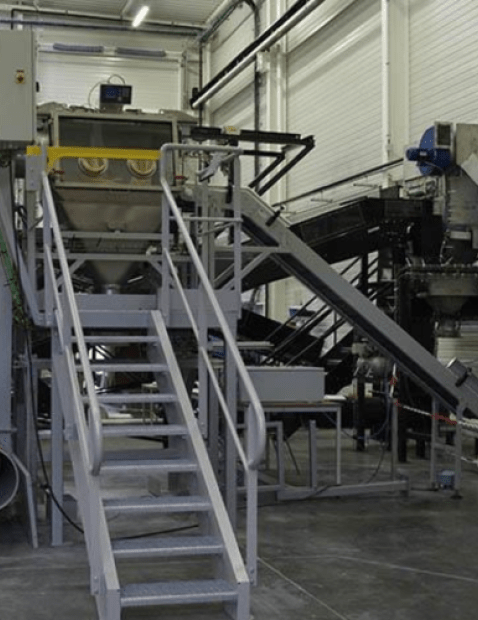

Palamatic Process solutions featuring cobots

Palamatic Process offers innovative solutions combining cobots with advanced industrial equipment:

- Sensitive powder decompaction: Using SmashR® technology, cobots ensure safe and precise material decompaction before transfer.

- Automated filling: Flowmatic® 02 and 03 stations, paired with cobots, guarantee fast, loss-free packaging.

- Toxic powder containment: Cobots work with containment systems to minimize operator exposure risks.

Industrial applications where cobots make a difference

Cobots find their place in a wide range of industries thanks to their versatility and adaptability.

Food industry

- Applications: Palletizing, packaging, delicate product handling.

- Example: Packing fruits or candies without damaging them.

Pharmaceutical and chemical industries

- Applications: Precise dosing, sterile containement handling, reactor filling.

- Example: Automated loading of toxic substances while protecting operators.

Would you like to find out more? Read our case study on pharmaceutical packaging automation with cobots.

Logistics and automotive

- Applications: Small part assembly, quality control.

- Example: Automated visual inspection of components using 3D cameras.

Pricing and return on investment (ROI)

How much does a cobot cost?

Cobots generally range between 20 000$ and 50 000$ CAD, depending on the model and specific features. While this may seem high, it is less expensive than traditional robots, particularly due to reduced infrastructure needs.

ROI benefits

Cobots offer an attractive ROI through:

- Reduced installation costs: No need for physical barriers or heavy infrastructure.

- Increased productivity: They handle repetitive tasks, allowing operators to focus on higher-value activities.

- Enhanced flexibility: Easily adaptable to new production requirements.

- Reduced labor costs: Cobots enable cost savings while maintaining consistent and efficient production.

Discover Palamatic Process' range of cobots and collaborative robots

Future trends in industrial cobotics

The future of cobots is promising, with innovations such as:

- Integrated AI: Cobots will continuously optimize their performance through autonomous learning.

- Expanded applications: Use in extreme environments (radioactive, underwater).

- Advanced materials: Built from lighter, more durable components, reducing their energy footprint.

For more information, visit the IFR (International Federation of Robotics) website.