SmashR®: The Intelligent Lump Breaker to Automatically Break Lumps and Massage Your Bulk Bags

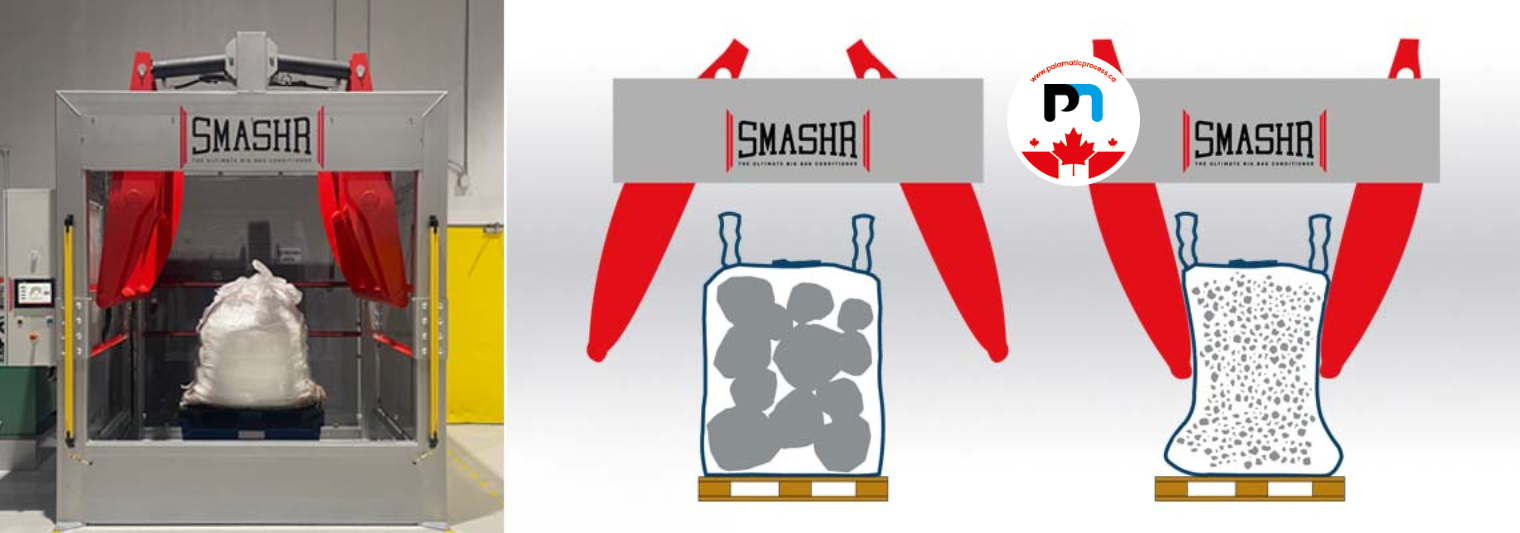

In industries handling powders or bulk products, prolonged storage or transport can cause the formation of compacted blocks inside flexible containers (bulk bags). This not only hinders material flow but also compromises dosing performance and overall production yield. To address this issue, Palamatic Process developed the SmashR®, an innovative and automated lump breaking system, capable of effectively breaking up lumps thanks to an intelligent motorized massaging unit.

Equipped with a motorized conveyor on a lift table, a barcode reader, and automated cycle management based on the type of large bag, this solution offers a high level of customization, traceability, and performance. It helps ensure powder fluidity and maintain the quality of downstream processes, without manual intervention.

In this article, we offer a deep dive into the tool's operation, its concrete benefits, and answers to frequently asked questions about this innovative equipment.

1. The SmashR®: An Automated Lump Breaking and Mechanical Stress Station

The SmashR®: An Automated Lump Breaking and Mechanical Stress Station

Equipment Structure: Lift Table, Motorized Conveyor, Receiving Hopper

Our equipment is a complete industrial solution, designed to be integrated upstream of a discharge station or dosing system. It consists of several robust and complementary mechanical elements:

- A motorized conveyor: allows for the automatic conveying of bags intended for solid bulk material to the treatment area without manual intervention, thus ensuring a smooth and continuous feed.

- A hydraulic lift table: precisely adjusts the height of the bulk bag to position the area to be massaged at the level of the massage heads. It adapts to different bag dimensions.

- Motorized massaging arms: these lateral actuators apply targeted pressure to the sides of the flexible storage container to break internal lumps without puncturing the bag.

- An optional receiving hopper (at the outlet) allows the process to continue towards a transfer screw, a sifter, or a dosing module.

This modular and automated structure guarantees repeatable, safe, and ergonomic treatment, even with heavy or difficult-to-handle bulk bags.

Massage and Lump Breaking Operation

The operating principle relies on an automatic pressure cycle, programmed based on the type of bulk bag and the nature of the product. Once the bag is loaded via the conveyor, the lift table positions the bag at the optimal height. The motorized arms then massage the sides at regular intervals according to a defined sequence.

This controlled pressure movement breaks up the compacted blocks formed inside the bag, thereby freeing the material and preparing the bag for smooth discharge without jolts.

Our machine also allows operation in cyclic mode or intelligent mode, with dynamic adjustment of the pressure applied based on the resistance encountered. Everything is controlled via a touchscreen and a user-friendly interface integrating custom recipes.

2. An Intelligent System Adapted to Each Client

Automatic Management of Massage Cycles Based on Bulk Bag Characteristics

Each handled product has its specific characteristics: some form friable lumps, others very compact blocks, while particle size or moisture can vary considerably. That's why our lump breaking unit integrates intelligent management logic for massage cycles.

Thanks to a programmable logic controller (PLC), the equipment automatically adjusts:

- the pressure intensity of the motorized arms,

- the massage duration,

- the number of cycles needed before discharge authorization,

- the vertical position of the pressure via the lift table.

These settings are adapted based on the detected bulk bag type, thus ensuring personalized treatment for each product reference, without requiring human intervention. Result: fewer errors, better material flow, and increased productivity.

Recipe Programming via Barcode Reader

It integrates a barcode reader which plays a central role in the traceability and automation of the process. Upon the arrival of an FIBC on the conveyor, the reader immediately identifies the product reference and triggers the appropriate massage recipe.

Each recipe contains the following parameters:

- cycle time,

- actuator force,

- massage height range,

- product type (fine powder, granule, hygroscopic...).

This optical reading avoids any manual entry, makes the operation reliable, and allows for instant adaptation even during multi-reference production. If modifications are needed, an authorized operator can edit the recipe via the Pal'Touch® HMI.

How Does Automatic Massage Cycle Management Work?

Our material preparation system uses a PLC connected to a barcode reader to trigger an appropriate massage cycle for the detected FIBC. Once the code is read, the system automatically loads the corresponding recipe (intensity, duration, frequency, position). This operation ensures homogeneous treatment, adapted to the product, without manual intervention, and limits human errors.

Do you have a powder transfer project ?

I am available to assist you.

Loïc, expert in powder handling

3. Automation, Traceability, and Operator Safety

Automation, Traceability, and Operator Safety

Integrated Automation and Time Savings

Our deagglomeration solution is designed to operate with perfect autonomy. Thanks to its integrated automation, the entire cycle – from identifying the flexible bag to the end of the massage – is performed without human intervention. The station is fully integrated into modern industrial logic:

- Automatic detection of the flexible container at the entrance via motorized conveyor.

- Barcode reading and automatic recipe loading.

- Massage cycle initiated according to programmed settings.

- Visual signal for end of treatment and transfer to the discharge station.

This automation provides significant time savings, reduces the risk of human errors, and frees operators from strenuous and repetitive tasks. It thus fits into a logic of streamlining flows, with increased machine availability.

Operator Safety: Confined Operation, No Product Contact

One of the major advantages of our technical solutions is the elimination of often dangerous manual interventions, such as tapping or direct handling of bags to break lumps.

The closed structure of the station, combined with position and safety sensors, prevents any contact between the operator and the motorized arms during the cycle. The bulk bag remains contained, and access is blocked until the treatment is fully completed.

Furthermore, by eliminating handling, the device limits musculoskeletal risks (MSDs), dust inhalation during premature opening of bags, and ensures a clean and safe working environment.

Why Integrate a Barcode Reader in a Powder Handling Process?

The barcode reader allows for automatic identification of the bulk bag type and loading the appropriate massage recipe. It ensures traceability, avoids manual parameter setting errors, speeds up batch changes, and enables multi-reference production without interruption. It is an essential tool to automate and ensure reliability of the station.

4. Intégration dans une ligne complète de manutention charges souples

Compatibility with Downstream Discharge or Dosing Systems

It is designed to be inserted directly upstream of an FIBC cleaning station, weigh dosing system, or pneumatic transfer system. Once the massage cycle is completed, the spouted bag is conveyed to the next station via a motorized or gravity roller conveyor, depending on the layout.

It can thus continuously feed:

- a buffer hopper equipped with a controlled flow device with a sealed connection,

- a screw or belt feeder to regulate flows,

- or a sifter to ensure material safety check before bagging.

This seamless interconnection makes our solution perfectly compatible with Palamatic Process automated lines, whether for filling, dosing, transfer, or packaging.

Synchronization with Discharge or Transfer Stations

The SmashR® station can be synchronized with the rest of the line thanks to its automated system. It exchanges data in real time with:

- the discharge station (availability signal, end of cycle),

- the dosing system (feed authorization after lump breaking),

- centralized control via Pal’Touch® (recipe tracking, performance indicators).

Thus, material flow management is optimized without overload or interruption, and each treated bulk bag then proceeds to immediate discharge, without requiring intermediate handling.

This approach ensures process continuity and maximum productivity, integrating lump breaking as an invisible but essential step in the line.

Is the SmashR® Suitable for Reinforced Textile Bags of Different Sizes?

Yes, it adapts to different flexible container formats thanks to its adjustable lifting platform and variable-amplitude massage arms. It can handle bulk bags from 500 to 1500 kg, whether they have 1 or 4 loops. Recipe management allows the correct parameters to be automatically loaded based on the format detected via the barcode.

Conclusion

Conclusion: A Key Asset to Optimize Your Production Flows

In an industrial environment where flow regularity and operator safety are major challenges, the system stands out as the ideal solution for treating bulk bags containing compacted products. Thanks to its automated lateral massage technology, its intelligent cycle management, and its simple integration into complete handling lines, it ensures smooth flow, without blockages, without manual intervention, and with total traceability.

Whether you handle fine powders, hygroscopic granules, or products with a strong tendency to cake, it provides a robust solution allowing you to maintain your throughput rates, improve the quality of your dosing, and reduce your maintenance costs.

Designed to adapt to your industrial constraints, our lump breakers can be custom integrated into your existing installations, or into a turnkey Palamatic Process line.