Heavy Lifting Handling Equipment – Bag Manipulators

1. Improve worker safety and production by reducing injuries related to heavy lifting of bags, bales, pallets, boxes and drums

In November of 2020, the Bureau of Labor Statistics released the latest numbers in work place injuries for the 2019 calendar year. In that report the agency states, “Injuries and illnesses to manufacturing workers resulted in 32,470 DAFW cases of sprains, strains, or tears (28.0 percent); 16,790 cases of soreness or pain (14.5 percent); and 15,380 cases involving cuts, lacerations, or punctures (13.3 percent).”

Repetitive, heavy lifting often can lead to these types of injuries to the shoulders, neck and lower back. Often times these injuries can range in severity from being a minor strain to a serious tear that requires weeks and months of rehabilitation. Considering the current economic climate of labor and material shortages, the last thing a manufacturer can afford is losing operators to working injury. Furthermore, production facilities have an obligation to take every measure they can to protect and minimize all risks of work-related injuries to their personnel.

Manually lifting and unloading heavy bags of powder and bulk solids is a common practice for many production facilities. These sacks of powder range in weight, but on average are between 50 – 100 lbs each. Depalletizing a stack of these sacks day after day by hand is only guaranteeing that eventually, operators will start having neck, shoulder and back issues.

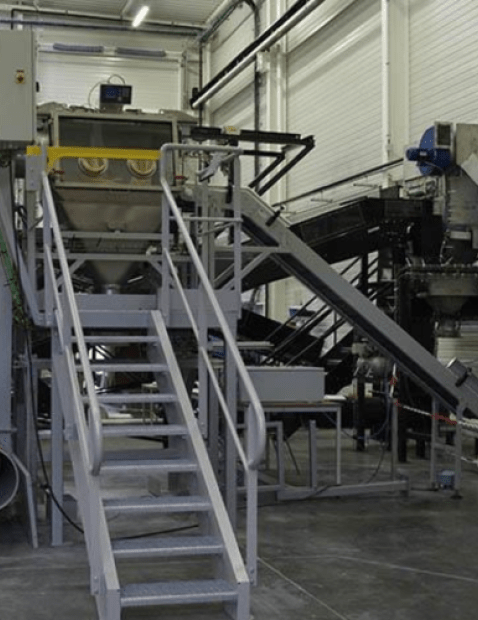

2. The Palamatic Process solution: Sack manipulator Manis®

The Palamatic Process Sack Manipulator Manis 160-1700 offers superior lifting capabilities with minimal operator effort. Operating off the principal of vacuum suction, the boot of the lifter can easily and gently adhere itself to paper, plastic and poly-woven sacks up to 175 lbs in weight. The material handling equipment setup is rather simple and easy to use. A vacuum pump is connected to a hose mounted to a jib crane.

At the end of the crane is an extendable and retractable lifting hose. A suction boot with simple controls completes the material handling system and allows the operator to control the intensity of the vacuum for lifting and lowering the packages.

Are you looking for a bag handling system?

I am here to help you with your study.

Loïc, bag handling expert

3. The advantages of a vacuum lifting system

Utilizing a bag vacuum lift in your bulk material handling process can provide the following production benefits:

1. Reduced risk of working injury

Bag lifters are designed to make repetitive lifting of heavy loads easy and ergonomic, eliminating strain and muscle fatigue. The lift and lower controls are simple enough to use one hand and almost all the weight of the load is carried by the suction of the vacuum pump.

2. Increased Productivity

Since repetitive lifting is made easier by the equipment, operators can palletize and depalletize sacks of material faster and easier. Less muscle fatigue, reduced strain, easy to use equipment all contribute to an increase in productivity. Increased productivity results in better production output and fulfilling orders faster and more efficiently.

3. Adaptability to various lifting requirements

Vacuum lifters aren’t just only suitable for paper and plastic sacks of material. Quick connection designs allow for the easy interchange of parts to allow for the lifting of other types of containers, including:

Furthermore, vacuum lifting equipment can be modified to work best in your process area. Examples of installations include:

- Rotating post on a mounted jib crane

- Inverted rotating post on jib crane (lower height requirements)

- Mounting for support structures (ceiling or support beams)

- Fixed columns to support lift equipment over a larger area

- Telescoping beams to reach areas with limited access

Vacuum lifting equipment is easy to use, install and can prevent operator strain and injury for a minimal cost.

Since 1992, Palamatic Process has provided materials handling equipment to over 2000+ installations in over 30 countries. We offer knowledge and expertise in all manner of powder and bulk automated material handling needs.

Examples include, pneumatic conveying systems, mechanical conveying systems, pallet conveyors, screw conveyors, roller conveyors, turnkey solutions, material flow devices, food-grade design, bulk bag equipment, handling systems, belt conveyor, conveying equipment, etc.

Contact us today for assistance with needed material handling solutions and to request a quote.