The use of bulk bags in industrial processes can sometimes cause flow problems.

Some powders stored for a long time may have a tendency to compact and deaerate. When the operator opens the bulk bag chute on the emptying station, the stored powder does not flow! Palamatic has developed several solutions to remedy these flow issues and caking problems.

1. Preparation of the bulk bag: Crusher bulk bag

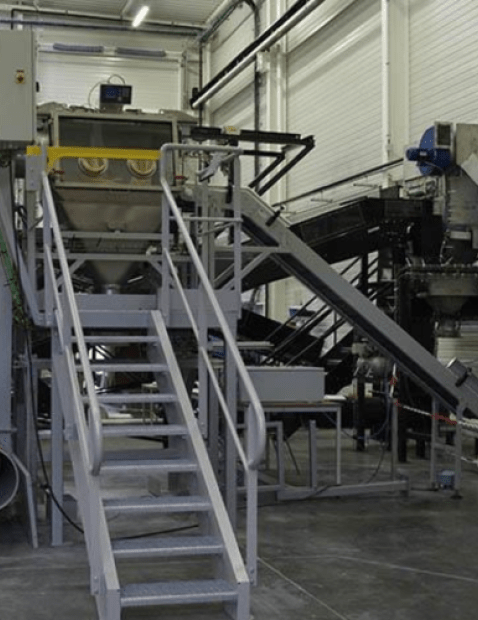

The SmashR® massage cage is the bulk bag preparation stand specially designed to cut fragment and break the caking powders stored in bulk bags. SmashR® " The ultimate bulk bag crusher " ensures, by means of two push rods articulated by a hydraulic unit, a penetration into the heart of the bulk bag. The bulk bag crushing solution on an upstream bulk bag preparation stand makes it possible to use the equipment at all of your bulk bag emptying stations.

The experience acquired by Palamatic in bulk bags guarantees deagglomeration of all types of powders: bulk bag of milk powder, bulk bag of oxide, bulk bag of sugar, bulk bag of carbonate, etc.

The Palamatic bulk bag crusher is available in several options: ATEX version, automatic loading of bulk bags, confined bulk bag crusher and high bulk bag crusher. Contact our technical services to book a crushing / fracturing test of your bulk bags!

Need advice on emptying your big bags?

I am available to discuss with you.

Loïc, powder expert

2. Pneumatic massage installed on the bulk bag emptying station

For the bulk bags already on the bulk bag emptying stand, Palamatic has been developing for more than 30 years a set of pneumatic paddles that masssage the sides of the bulk bag. The number of massage jacks varies from 2 to 6 depending on the powders processed. Cylinders positioned in the lower part make it possible to break the product bridge, and the pneumatic cylinders positioned in the upper part make it possible to break the agglomeration.

This pneumatic bulk bag massager solution can be added to existing bulk bag stations. Do not hesitate to contact our sales department to study this flow solution.

3. Bulk bag vibration

Vibrating bulk bags is a possible solution to improve flowability. However, this vibration can have the opposite effect if not properly designed and implemented! Vibrating the bottom of the bulk bag by installing an electric vibrator on the supporting tray of the bulk bag station requires preliminary precautions. The bulk bag emptying structure must be compatible with the forces generated by this vibration. The powder handled must be dry in order to avoid settling and the risk of amplifying the agglomeration of the material.

The Palamatic test station integrates all the powder unclogging solutions. We encourage you to visit with our test operators to select the crumbling solution best suited to your process needs.