Description

FLOWMATIC® 10 BULK BAG FILLING - HIGH SPEED PACKAGING LINE WITH MAXIMUM HYGIENE

The FlowMatic® 10 high rate bulk bag filling system allows high speed packaging while maintaining maximum hygiene when handling your super bags.

Designed for the pharmaceutical and food industries, this equipment is designed for clean room/white area FIBC loading and transfer to an external storage area. Commercial weighing associated with the pallet supply line and big bag transportation automation allows the preparation of large volumes ready for sale with little intervention by human operators.

The FlowMatic® 10 series is designed to fill big bags, FIBCs, super sacks and jumbo bags in the clean side / white zone of a hygienic operation and extract them to an external storage area. An SAS (gray zone) closed by two hermetic doors makes it possible to make the connection between the two zones and avoid introduction of the pallets in the white zone. The FlowMatic® 10 system is ideal for pharmaceutical filling operations, dairy powder processors, food manufacturers, and any industry requiring sanitary and hygienic filling / loading equipment.

-

Automation4

-

Rate3

-

Overall dimensions2

Equipment advantages

- Automatic loading and unloading of big bags

- Commercial weighing with net weighing

- Station with pre-dosing hopper

- Conveyor and automation

Media

View our equipment in videos

FlowMatic® 10 Bulk bag filling

Bulk bag filling range

View our equipment in photos

Specific conditioning for milk industry

Once packed, the big bag is placed on the pallet and removed by a motorized roller conveyor, thus optimizing the flow rate of the big bag packing line.

Big bag filling line

3D view of the high rate filling station with maximum hygiene.

Bulk bag filling system - FlowMatic® 10

Hygienic conditioning station installed under an atomization tower for infant milk powder.

High rate bulk bag conditioning

A SAS (grey zone) closed by two hermetic doors makes it possible to make the link between the two zones and avoids the introduction of pallets in sensitive areas.

Big bag & drum filling

Complete line of micronization and packaging in bags and drums of chemical products.

Conveyor on bulk bag filling

Belt conveyor at the exit of the filling station for big bags of spices.

Big bag production line

Once packed, the big bag is placed on the pallet and removed by a motorized roller conveyor, thus optimizing the flow rate of the big bag packing line.

Big bag filling station FlowMatic® 05-HC

Milk powder packing station on an industrial production line.

Sugar packaging

Powdered sugar packing line in storage big bag.

Automatic bulk bag filling complete line

Industrial production line with filling station for big bags of sugar.

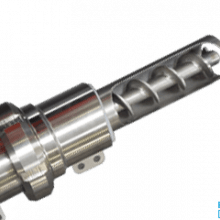

Load cells

The big bag is suspended in height via a pneumatic cylinder.

Bulk bag filling Palamatic process

Roller conveyor on big bag packing line.

High rate big bag loader

Automatic big bag filling line for conditioning milk powder with big bag sealing.

Milk powder packaging

Hygienic big bag conditioning station for infant milk powder for the preparation of infant milk powder.

Big bag packing

High rate bulk bag filling

Industrial production line for the filling of big bags in the chemical industry.

Big bag filling line - FlowMatic® 10

Big bag filling on industrial production line processing bulk materials and powders.

Control cabinet

Big bag filling on an industrial conditioning line for bulk materials.

Automation

Industrial automation on a big bag packaging line for detergent.

Features

Technical specification

| Rate | 10 to 20 big bags/h. |

|---|---|

| Capacity | 2 tons/big bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 15kW |

| Compressed air consumption | 4,9Nm³/h. |

| Dust removal rate | 300 m³/h. |

Finishing touches: RAL 3006, micro-blasted, electropolishing

Average power consumption: 3.8 kW

Operating pressure: 6 bar

Input 4-20 mA: 1

Digital input: 23

Digital output: 17

Accuracy of the weighing chain: +/- 500 gr.

Maximum big bag dimensions Length * Width * Height: 1,300 * 1,300 * 2,400 mm

Equipment integrated into the FlowMatic® 10 model:

- Vibrating packing table

- On-board conveyor on lifting table

- Storage area

- Pallet unstacker

- Bulk bag removal hanging trolley

- Gray area: bulk bag extraction by quick sealing hermetic doors

- Lift door SAS

- White areas

- Filling head

- Weighed frame

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Packing in a white room environment

Processed powder: Powder milk - Packing in a white room environment - Hygienic packing station under an atomization tower for infant powdered milkFood and Animal Feed

Handling of food starch

Processed powders: gluten and starch - Handling of food starch - French company specialized in the conditioning of bulk products and raw materials.Food and Animal Feed

Clean room for packing

Processed powder: milk powder - Clean room for packing - A leading dairy and manufacturer of high value-added milk powder for the leaders in the infant market.Food and Animal Feed

Receive our quotation in 3 clicks!