Description

Conveyor solution for materials requiring flexible layout

The tubular chain conveyor or tubular cable conveyor operates at low speed.

This low speed guarantees transport without product damage, and makes it available in ATEX versions. It is particularly suitable for transferring fragile products.

The system is totally dust-tight and self-cleaning. Its design has virtually no dead space.

The discs, molded to FDA-approved food-grade quality, are mounted on the links of a stainless steel chain or steel cable that carries the product through the tube.

The chain acts as a seal as the product is transferred through the tube, enabling a conveyor to make multiple changes of direction.

There are 2 types of conveyor: the aeromechanical conveyor (aero-conveyor) and the tubular chain or cable conveyor.

Discover our white paper on the difference between a tubular conveyor and an aeroconveyor.

-

Rate4

-

Ease of implementation4

-

Hygiene4

Equipment advantages

Tubular chain conveyor

- Multiple inlets and outlets

- Conveyor can be stopped when full

- Easy maintenance & handling

- Operational safety

- Small footprint

- Low energy consumption and operating costs

Media

View our equipment in photos

Bulk transfer in the food industry

The food-grade molded discs are FDA-approved.

Mechanical transfer

Catalyst sampling plant.

Mechanical transfer of friable products

The chain conveyor transports fragile, brittle products gently, without damaging them.

Aeromechanical conveyor

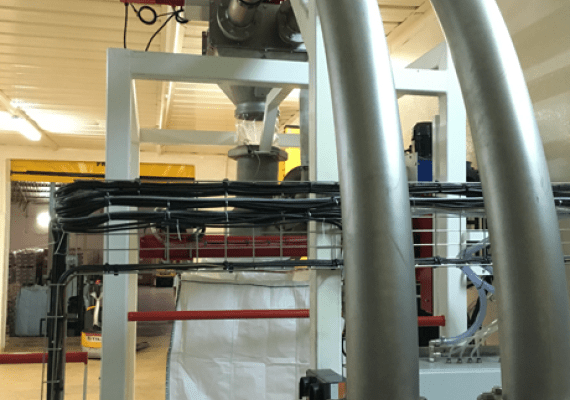

Conveying bulk products requiring flexible layout.

Waste conveyor

Tubular chain conveyors are used in the recycling industry.

Tubular chain conveyor

Chain conveyor with self-cleaning disc system.

Mechanical transfer

The aeromechanical conveyor is used to convey and dose bulk products such as plastic granules and powders, expanded polystyrene, dried vegetables, coffee, tobacco, sugar, flour, milk, cocoa, talc, pigments...

Tubular conveyor

Conveyor for bulk goods.

Aeromechanical transfer

Chain utilization depends on the power required and the length of the conveyor.

Transfer in the metallurgical industry

Mechanical sand conveying.

Features

Technical specification

Chain conveyor

The chain conveyor has a sealed design.

The discs, made of synthetic material, are mounted at regular intervals along a chain or cable. Motorization and a drive wheel indexing the disks rotate the cable or chain.

These same discs ensure the system's self-cleaning.

- The use of chain depends on the power required and the length of the conveyor.

- Aeromechanics using cables enables the equipment to be used in the food industry.

Tubular chain conveyors or tubular cable conveyors

Disks are molded and manufactured in FDA-approved food-grade quality. They are mounted on the links of a food-grade stainless steel chain, for use in food and pharmaceutical applications in a sanitary environment.

It can be fed via multiple infeed points, and can discharge product at several outfeed points.

The tubular conveyor can be installed on a mobile structure, particularly during truck loading operations.

Its high efficiency also enables heavy, demanding products to be conveyed at high flow rates (50 t/h), making it suitable for all sectors of activity.

5 tube diameter sizes are available: 115, 135, 160, 200 and 270.