Despite their similarities, aero conveyors and tubular chain or cable conveyors (Tube chain conveyor) are quite different.

1. Principle of the aero conveyor

As the name suggests, an aero conveyor (or aeromechanical conveyor) uses air to convey materials. Molded discs on a cable move at very high speeds in a steel tube which in turn creates airflow. The product is then transported by this flow of diluted air.

The aero conveyor is cost effective and allows installations in restrictive spaces as well as adapt to multiple configurations. They are particularly suited to feed mobile stations or decondition bags of ingredients in the agri-food industry.

2. Chain tubular conveyor (or cable conveyor)

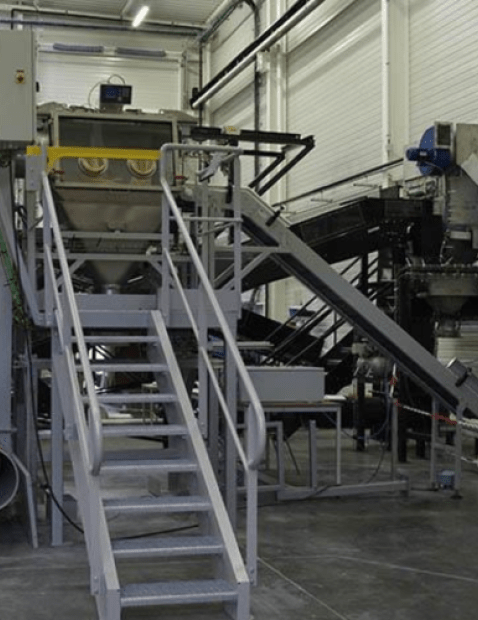

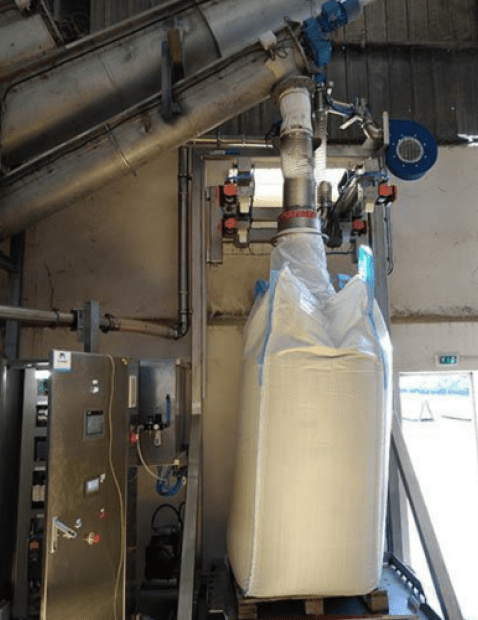

The tubular chain conveyor, or tubular cable conveyor, operates at low speeds. Discs held together by a stainless steel chain, or a steel cable, pulls the product into a rectified steel tube.

The tubular chain conveyor is therefore particularly suitable for the transfer of fragile products. Its high efficiency also allows the conveyance of heavy and demanding products at high speeds (50 t/hr). The low conveyance speed allows the safe transport of explosive materials in an ATEX zone.

Another advantage is the ability to power the system from multiple points. Exit boxes allow the product to be emptied at several exit points.

If your require further assistance,

I am at your entire disposal.

Loïc, powder expert

3. Comparative

Advantages of air-goods and chain tubular conveyors over other systems such as transfer screws, bucket elevator, conveyor belts, and pneumatic transfers.

Both of these mechanical disc conveyors have the best energy efficiencies on the market for medium to long-distance conveyors. Their power-to-flow ratio is very high compared to other systems.

The very design of these conveyors gives them excellent cleanability. They have almost zero retention as nearly all the product is conveyed.

Their design is completely waterproof and dust tight which means no need for filters or other containment equipment.

Only one piece of equipment is needed for conveying in multiple directions.

4. How do I choose between the two then?

Below is a decision support table based on your requirements.

| Aéroconveyor | Tubular chain/tubular cable conveyor | |

|---|---|---|

| Cost | $ | $$$ |

| Gentle on product | Good | Very Good |

| Elbows |

- With angle return - As much as needed |

- With corner return (the disc cannot derail) - Limited in number |

| Full Conveyor Stop | No | Yes |

| Multiple inlets and outlets | No | Yes |

| Cable Voltage Station | Yes, automatic | Not needed |