Description

Conveying of materials requiring flexibility of implementation

Flow rate from 1 to 40 m³/h.

Elevation up to 10 m.

Conveying length up to 50 m.

Robust design enabling the conveying of a wide variety of products, whether heavy or sticky; discs ensure the self-cleaning of the system.

The conveyor is tightly designed through the integration of tubes and angle gears. The disks, manufactured in synthetic material, are mounted at regular intervals along the chain or the cable.

Operating mode of the aero conveyor :

The inlet of the material is performed at the level of the angle gear pulleys or directly on the conveying tube. The inlets can be multiple.

The outlets fo the material are performed at the level of the pulleys or directly on the tube according to methods with specific valves that are peculiar to the system.

-

Rate4

-

Ease of implementation4

-

Hygiene4

Equipment advantages

- Self-cleaning disk system

- Compliance with crumbly and fragile materials

- Conveying of materials with heterogeneous density and particule size

- Flexibility of implementation

Media

View our equipment in photos

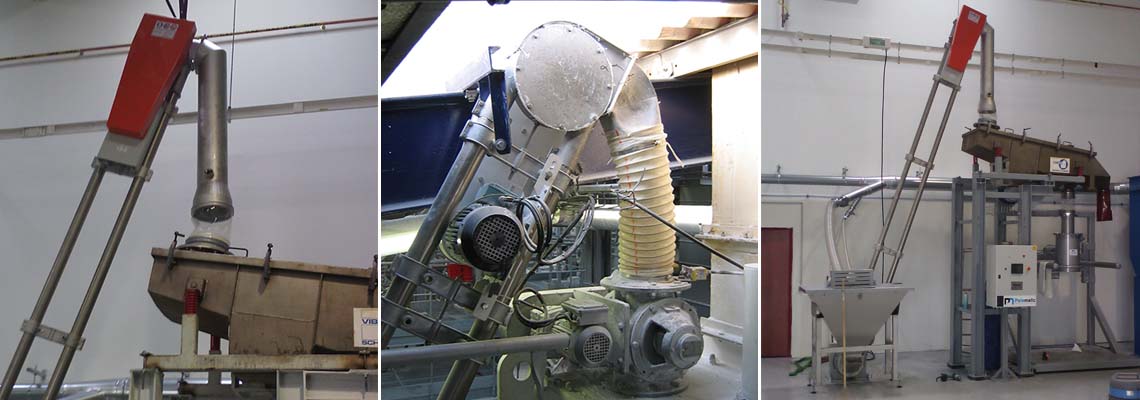

Convoyeur aéromécanique Palamatic Process

Aeromechanical conveyor for loading a big bag filling station

2 aeromechanical conveyors ensure the loading of a screening machine.

Features

Technical specification

| Capacity | 1 to 40 m³/h. |

|---|---|

| Elevation | Up to 10 m |

| Conveying lenght | Up to 50 m. |

| Tube Ø in mm | 88,9 - 114,3 - 139,7 - 168,3 - 219,1 |

| Capacity in m³/h | 1 to 4 |

| Disk movement speed in m./ss | 0,02 to 0,45 |

- The use of the chain is related to the power implemented and the length of the conveyor.

- The aero conveyor engineering using cables allows the implantation of the equipment in food grade industries.

2 aero conveyors ensure the loading of a sifter (scraping disks manufatured in food grade nylon)

Maximum rate: around 5m³/h.

Vertical conveying length 3 m.

Buffer hopper capacity: 300 litres

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Disperser feeding

Poudres traitées : silice pyrogénée, aerosil, carbonates de calcium, imersil, graphite expansé - Alimentation disperseur - L'installation est composée d'un poste de vidange de sacs dépoussiéré couplé...Chemical