Processed product: tomato powder

Industrial process for tomato products

Manufacturer of tomato sauce and tomato powder from fresh tomatoes.

The application requested by the customer is the filling of big bags and cartons at the outlet of the atomization tower.

The customer requires a hygienic conditioning of the powder in big bags and cardboard boxes.

Customer data:

Cardboard boxes: 20 to 25 kg

Big bags: 500 and 1,000 kg

Feed rate: 2t./h.

Density: between 410 and 500 kg/m³

The entire processing line is protected by a magnetic sensor system.

A sampler ensures product quality control by the production teams.

A buffer hopper provided with a two-way conveying screw ensures the feeding of the bag/cardboard line or the big bag line.

Packing is carried out in a controlled atmosphere and the packagings are welded by double sealing bars.

Bag/cardboard box line

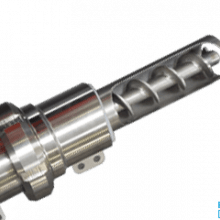

The operator positions the bag on the weighed packaging head. The hygienically designed twin-screw dosing unit ensures the product is accurately dispensed. The flexible sleeve avoids any weighing interference.

The sealer integrates a vacuum and nitrogen injection system into the packaged product.

The handling of the cardboard boxe is ensured by a manipulator with a suction seal.

Big bags line

The big bag packaging line installed in parallel with the carton line ensures hygienic packaging of the big bag and dosing of the bulk material. The filled big bags are placed on a wooden pallet. However, the use of the FlowMatic® 04 H model prevents the introduction of pallets into the packaging area.

The principle of operation is the docking of the big bag on its pallet via a double level conveyor. The big bag is conveyed via a motorized belt to the packaging area.

This solution ensures the required hygiene constraints with a reasonable investment compared to aerial handling solutions for big bags.

The dosing units are of hygienic design with easy disassembly.