Automated packaging process for filter cake in big bags

The BaggerCake® process line, specifically designed to meet the needs of the battery industry, aims to revolutionize big bag packaging of filter cake generated at the end of the filter press. The filter presses in this line are commonly used for the preparation of nickel, manganese, cobalt, lithium sulfates and hydroxides.

When the filter cake is discharged from the filter press it is fed to a screw conveyor which helps in breaking it up. The screw then transfers the product to a semi-automatic or automatic big bag filler. Equipped with advanced features, this filler can automatically close the big bag once the preset weight has been reached.

A vibrating table for the BaggerCake® 10, or a vibrating conveyor for the BaggerCake® 20 and 30, compacts and optimizes the quantity of product in the big bag and facilitates its evacuation.

This process guarantees maximum efficiency in filter cake packaging.

- Automated big bag packaging

- Automated filter cake deagglomeration

- Automatic big bag filling

- Automatic big bag closing at set weight (optional)

- Vibrating conveyor for optimization and automatic evacuation (optional)

- Automatic big bag positioning by robot (exclusive benefit of the BaggerCake® 30 model)

- Sequenced, automatic and confined production

Models

| BaggerCake® 10 | BaggerCake® 20 | BaggerCake® 30 | |

|---|---|---|---|

| Production capacity in big bags/h. | 10 | 20 | 20 |

| Weight control | Yes | Yes | Yes |

| Big bag conveying | No | Automated conveying | Automated conveying |

| Big bag positioning | Operator | Operator | Robot |

| Automated bigbag closing | Yes (option) | Yes | Yes |

Zoom on the BaggerCake® 10

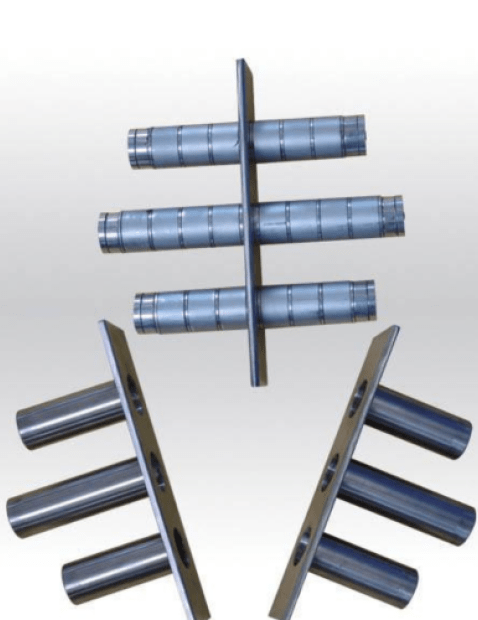

The BaggerCake® 10 consists solely of a screw at the filter press outlet to break up the filter cake, and a FlowMatic® 03 big bag filling station with vibrating table.

Optional extras:

- Automatic big bag closing with a clipper

- Double screw to load product into two separate big bag fillers

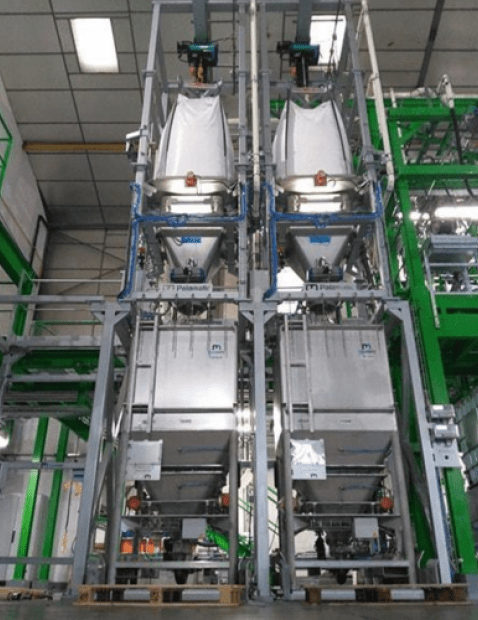

Zoom on the BaggerCake® 20

The BaggerCake® 20 process line is equipped with a FlowMatic®04 semi-automatic big bag filler. The big bag is positioned by an operator, but automatically closed and evacuated to buffer conveyors.

Zoom on the BaggerCake® 30

The BaggerCake® 30 distinguishes itself from other BaggerCake models by its unique advantage: automated big bag infeed into the filler, performed by a robot. This feature significantly increases process efficiency and safety, providing a state-of-the-art automated solution for filter cake packaging.

High output and enhanced safety

This automated packaging line represents a major asset for companies in the battery industry guaranteeing high-speed, automated and safe production. Process automation, coupled with Palamatic Process's experience in the battery industry, offers an optimized technical solution while eliminating the risks associated with handling toxic powders frequently found in chemical companies and gigafactories.

BaggerCake® process lines offer a complete, safe and efficient technical solution for filter cake packaging, meeting the specific requirements of the constantly evolving battery industry.

All the equipment integrated into the filter cake big bag packaging process line is available below.