Description

Confined big bags and bags unloading - glove box

Rate: 10 to 20 big bags/h - 180 bags/h

Capacity: 2 tons/big bag

Objectives: Total containment and operator safety

This variant incorporates a glove box that prevents the operator from coming into contact with the drained product, while maintaining good visibility.

The glove box prevents the operator from coming into contact with the drained product, while maintaining good visibility.

This big bag and bag station allows the ergonomic deconditioning of big bags and bags with the use of an electric hoist, a forklift truck or an overhead crane and available in a low version.

Discover our 3 types of loading:

-

Rate2

-

Automation1

Equipment advantages

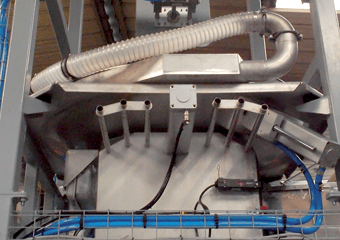

- Connection tube: totally airtight connection between the big bag and the unloading station.

- Containment tube: ensures a containment of the produt flow during the opening phase of the drain sleeve and offers the operator.

- Deposit tray massage: the flow of the product is optimized by the installation of a pneumatic massage system.

- Carton deconditioning: the opening of the unloading station allows the deconditioning of different types of containers, bags, cartons.

Media

View our equipment in photos

Big bag and sack discharging glove box

Containment and protection of operators.

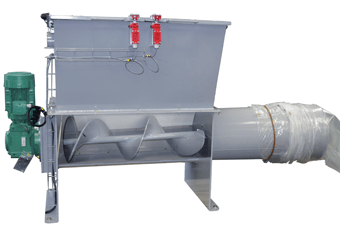

Glove box - Contained discharge

The stripping box with dust-tight door provides safe and ergonomic access to the bulk bag discharge spout.

3D layout - Big bag & sack discharging low profile

Duopal® DP23 with low structure

Space saving and flexibility, sack dump station, big bag discharge station, containment.

Bulk bag & sack discharging

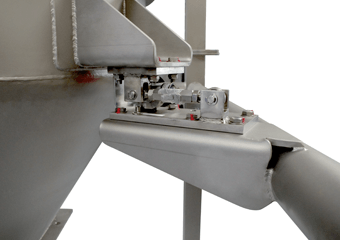

Telescoping tube: make a fully dust-tight connection between the bulk bag and the discharge station.

3D layout - Big bag & sack discharging electric hoist loading

Duopal® DP23 with electric hoist loading

Space saving and flexibility, sack dump station, big bag discharge station, containment.

3D layout - Big bag & sack discharging Forklift truck loading

Duopal® DP22

Space saving and flexibility, sack dump station, big bag discharge station, containment.

Bulk bag dicharging - Glove box

The stripping box optimizes containment and enables the handling of toxic bulk materials.

Features

Technical specification

| Rate | 10 to 30 big bags/h - 180 sacks/h. |

|---|---|

| Capacity | 2 tons/big bag |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power |

0.1kW (depending on option) |

Integrated equipment:

- Handling cross

- Support structure

- Pneumatic cylinders for massage system

- Big bag deposit tray

- Stripping box with airtight door

- Hoist remote control

- Containment tube inside

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Manufacture of industrial glue

Processed powders: varnish and gelcoat - Manufacture of industrial glue - This process consists of a combined Duopal® DP02 station for emptying sacks and big bags, a pneumatic conveying system and a...Chemical