Description

Big bag and bag unpacking station - Suction tube - Multi-product vacuum emptying

Flow rate: 50 kg to 2 tons/hour

Manufacturing: steel, 304L stainless steel, 316L stainless steel

For partial discharging, multi-products & integrated weighing

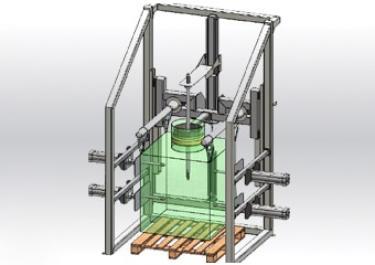

System of automatic big bags and drums unloading through a retractable suction tube that vacuums the bulk material. This station, from the EasyFlow® range, offers you the possibility of partially or totally emptying your big bag to make multi-product recipes. Integrated weighing makes it possible to precisely control and manage the amount of product to be vacuumed

The EasyFlow® Flex big bag unloading station has been designed by Palamatic Process to purge the desired quantity of materials precisely (via a weighing system) by vacuum. The possibility of evacuating a semi-unloaded big bag is the main objective of this machine. With EasyFlow® Flex, a single station is sufficient for multi-product discharging. It is the combination of a VFlow® conveying system and a big bag station. This station allows automatic unloading operations without operator intervention. Big bags are positioned using a simple pallet truck or forklift..

Operating principle:

- The big bag is positioned on the station using a pallet truck. The operator connects the mouth of the big bag

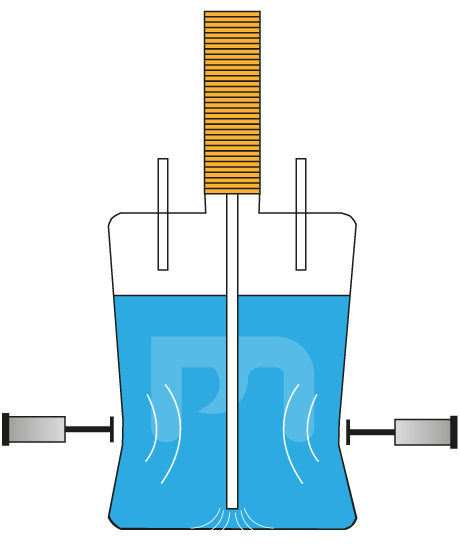

- The telescopic tube, connected to the pneumatic conveyor by suction, plunges into the big bag

- A big bag massage device, coupled with a ventilation system, allows a refocusing of the product for a total emptying of the big bag

- The big bag lifting system has a dual purpose:

- 1) ensure weighing without interference;

- 2) optimize the flow of the product

- Reclosing of the empty or semi-empty big bag

-

Rate4

Equipment advantages

- Fan for big bag shaping

- Weight cells for management of bulk materials vacuum

- Adaptable to any big bag (dimensions)

- Connection to the vacuum conveying system VFlow®

Media

View our equipment in videos

EasyFlow® Flex - Big bag discharging

View our equipment in photos

Flour discharging

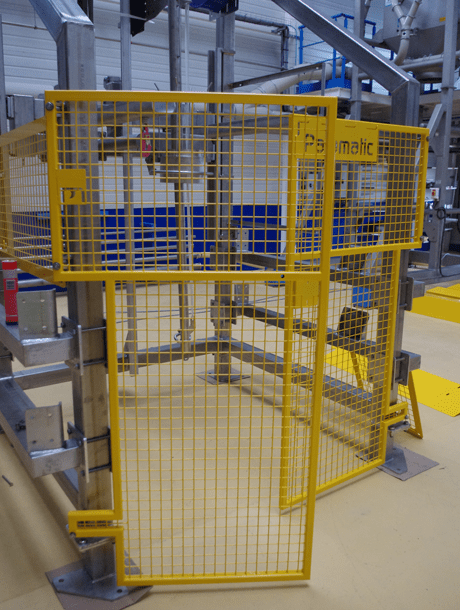

Big bag discharger EasyFlow® Flex with a suction tube.

Bulk bag discharching with telescopic suction pipe

For partial discharge, multi-product & built-in weighing.

Placing of the big bag

Big bag shaping fan to help vacuum the bulk material at the bottom of the big bag.

Food powder discharging

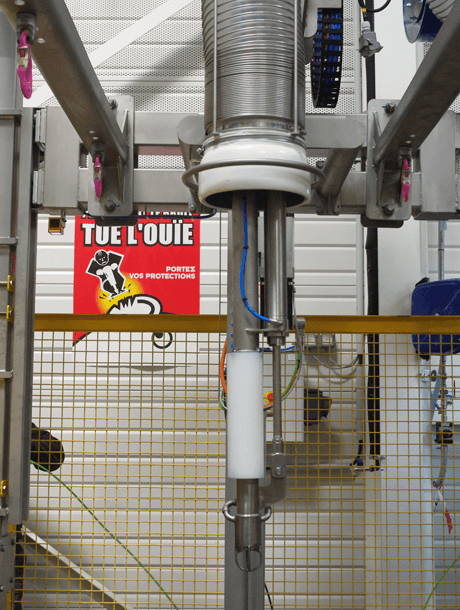

Lowering of the telescopic tube.

Big bag discharging suction pipe

Multi-product big bag discharge by vacuuming.

Features

Technical specification

| Flow rate | 50 kg at 4 t./h |

|---|---|

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 1 to 8 kW |

Dosage accuracy: 500 grams (may vary depending on the density of the product)

Equipment integrated into the EasyFlow® Flex model:

- Telescopic suction tube: the suction tube plunges into the centre of the big bag. Its descent is controlled continuously or controlled by the level sensor fixed at the end of the tube and which detects the "product lack".

- Inflatable seal: the chute of the big bag is connected to an inflatable seal to seal the assembly.

- Blowing fan: the big bag blowing fan ensures a constant shaping of the big bag in order to facilitate the complete emptying of the big bag (no folds)- Control cabinet: the cabinet allows to control the quantity of suctioned product

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Raw material dosing

Processed powders: milk powder, salt, sugar and additives - Raw material dosing - This project concerns the deconditioning of raw materials in big bags for the feeding of 2 Viennese pastry production...Food and Animal Feed

Contained feeding of pharmaceutical ingredients

Processed material: titanium dioxide - Contained feeding of pharmaceutical ingredients - Big bag discharge by vacuum pipe for the contained feeding of pharmaceutical ingredients.Fine chemical

Manufacture of glass wool

Material handled: sodium nitrate beads - Manufacture of glass wool - The client, a world leader in insulation solutions, required installation of a pneumatic conveying system for the transfer of...Chemical

Tank feeding

Processed powders: Cobalt Carbonate, Cobalt Hydroxide & Cobalt Oxalate - Tank feeding - The purpose of the installation is to feed a preparation tank with the product packaged in big bags.Energy