Description

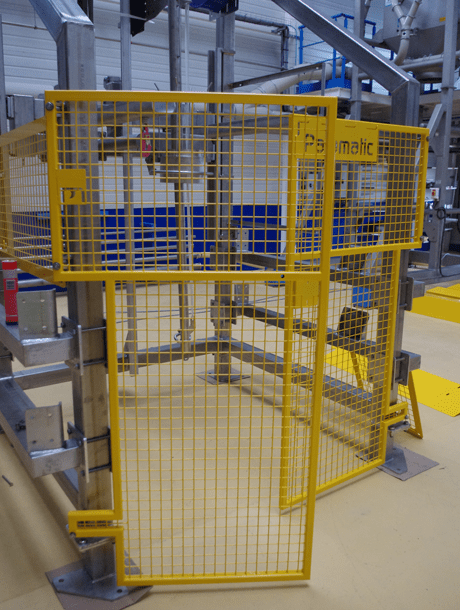

EasyFlow Flex OEB Discharge System for Powders and Sensitive Products

Discover the EasyFlow Flex OEB system, designed for the secure discharge of sensitive powders, ensuring emission control and compliance with OEB standards.

The EasyFlow Flex OEB system offers a safe and efficient solution for discharging powders and delicate products from bulk bags.

With advanced technical features, it ensures a high level of containment to meet OEB (Occupational Exposure Banding) requirements, safeguarding operators and protecting the work environment.

- Designed for industries handling active or toxic powders

- Applications: pharmaceutical, chemical, and food sectors.

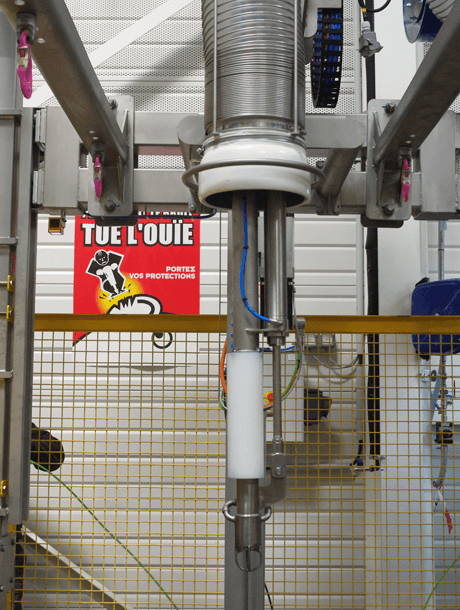

OEB Containment

The EasyFlow Flex OEB system complies with containment levels OEB 3 to 5, limiting dust emissions and providing optimal operator safety.

Materials and Design

Constructed with stainless steel and durable materials, the EasyFlow Flex OEB system is suited for demanding environments. Its modular design allows for seamless integration into existing facilities.

Easy Maintenance

The system is designed for quick disassembly, enabling easy maintenance and reduced downtime.

Industrial Applications

- Pharmaceutical sector: suitable for APIs and active powders.

- Chemical sector: ideal for toxic and reactive powders.

- Food sector: optimized for handling sensitive powdered products.

-

Fragile material5

-

Containment5

-

Efficiency5

Equipment advantages

- Bulk bag shaping fan

- Load cells for product aspiration control

- Optimal emission containment

- Safe handling of active powders

- Reduced risk of cross-contamination

Features

Technical specification

| Throughput | 110 lbs to 8,818 lbs/h (50 kg to 4 t./h) |

|---|---|

| Construction Materials | Painted steel, stainless steel 304L, stainless steel 316L |

| Installed Power | 1 à 8 kW |

Dosage Accuracy: 500 grams = 17,64 oz (may vary depending on product density)

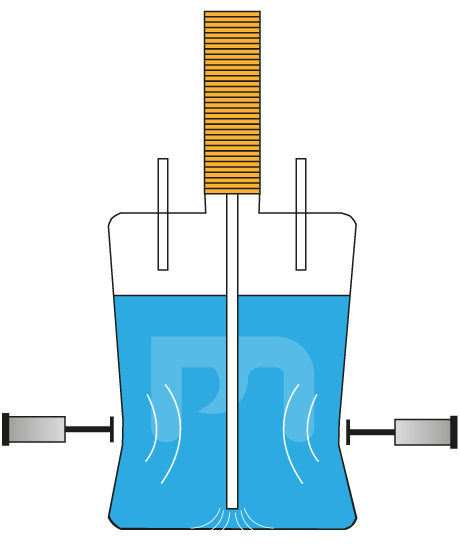

Safe discharge Process and Integrated Filtration Systems

The EasyFlow Flex OEB system is specifically designed to ensure the secure discharge of powders and particulate products in sensitive environments, such as the pharmaceutical, chemical, and food industries. It incorporates various features to minimize dust emissions and protect both operators and the workplace.

Steps in the safe discharge process

- Secure container connection

The discharge process begins with the secure connection of the container, whether it is a bag, drum, or another type of receptacle.

Locking and sealing mechanisms ensure maximum airtightness, preventing any powder leakage during connection.

- Controlled and progressive opening

The easyflow flex oeb system features controlled opening mechanisms for progressive discharge. This step is critical to preventing dust dispersion and maintaining a clean working environment.

- Emission containment

During discharge, non-return valves and sealing gaskets ensure total containment of the powder, even for potentially toxic substances. This containment meets oeb levels 3 to 5, ensuring operator safety and reducing the risk of cross-contamination.

- Secure powder transport

Once discharged, powders are transported directly to subsequent production stages without exposure to ambient air. This is achieved through a closed-loop transfer system, minimizing contact between the powder and the workplace environment.

Integrated filtration systems

The easyflow flex oeb system includes high-performance filtration devices to ensure optimal dust emission control.

HEPA filtration (High-Efficiency Particulate Air)

Equipped with hepa filters capable of capturing up to 99.995% Of fine particles, the system maintains extremely low emission levels, complying with oeb requirements and ensuring a clean working environment.

Multi-stage filtration

For ultra-fine or toxic powders, a multi-stage filtration system can be integrated. This setup involves coarse particle filtration followed by finer filtration for residual particles, ensuring maximum efficiency.

Automatic filter cleaning system

To maintain optimal filter performance, the easyflow flex oeb system includes an automatic filter cleaning mechanism. This feature prevents particle buildup on the filters, extending their lifespan and ensuring consistent efficiency.

Customizable options

- Confinement and filtration solutions tailored to specific needs.

Documentation and Compliance

- Comprehensive documentation and technical support

- Compliance with OEB and ISO standards

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Rubber calendering line

Processed powders: 2 references of carbon black (micro pearl) - Rubber calendering line - The facility includes 2 container discharge systems that supply 2 mixing lines with powdered carbon black.Chemical

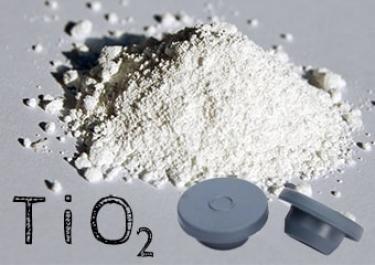

Contained feeding of pharmaceutical ingredients

Processed material: titanium dioxide - Contained feeding of pharmaceutical ingredients - Big bag discharge by vacuum pipe for the contained feeding of pharmaceutical ingredients.Fine chemical

Cement unloading and conveying

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton bulk bags with pneumatic transfer of material to silo storageMinerals and building

Unloading and filling of manganese dioxide big bags

Processed powder: lithium nickel potassium oxide - Unloading, filling of big bags and transfer of material - The objective of this installation is to protect the operators with equipment designed to...Energy