Description

Delicate mixing and blending, simultaneous storage of materials

The CV conical screw mixer is a conical mixer with high mixing efficiency. It allows the delicate mixing of powders, while ensuring the highest level of accuracy without deterioration. CV mixer is based on a three-dimensional action produced by an axis suspended from a rotating arm inside the conical tank combined with the rotation of the axis itself. This conical screw mixer is suitable for intermediate product storage, combined with temporary homogenization.

Operating mode:

-

Complexity of mixtures4

-

Rate2

-

Hygiene4

Equipment advantages

- Small dimensions

- Very gentle mixing, respect for the materials used

- Minimum material residue

- Low energy consumption

- Delicate action on the material

- Low powers

- Minimum heat production

Media

View our equipment in photos

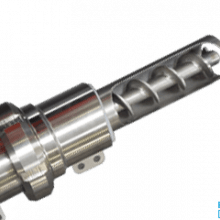

Conical screw mixer

The conical mixer is an inverted cone that is fitted with a large screw that rotates on itself inside.

Industrial conical screw mixer

The screw creates a lifting movement of the bulk material, bringing it to the center of the mixer.

Industrial conical mixer food industry

The mixing is gentle and guarantees precision in the blending without distortion of the bulk material.

Animal flour mixer

The conical mixer ensures fast and intensive mixing with low energy consumption and high accuracy.

Carbonate mixing

The blending is done gently and without overheating the mixed powder.

Conical mixer food application

These blenders for powders and granules are suitable for the food and pharmaceutical industries; they guarantee a good mixing as well as the absence of residues during the discharge.

Features

Technical specification

Capacity: 50 to 5,000 l.

Objective: sticky liquid mixture or wet, pasty or powdery materials

- Mixing vessel made of steel, stainless steel 304L/316L

- Surface finish: satin finishing, polishing, blasting

- Manual cylinder or pneumatic actuator for knife gate valve

- Adjustable knife gate valve

- Adjustable flow

- Minimum residual material in case of complete emptying

- Possibility of a mobile mixer

| Models | CV 50 | CV 100 | CV 200 | CV 300 | CV 600 | CV 1 000 | CV 1 500 | CV 2 000 | CV 3000 | CV 5 000 |

|---|---|---|---|---|---|---|---|---|---|---|

| B | 1,222 | 1,372 | 2,200 | 2,400 | 2,714 | 3,054 | 3,410 | 3,650 | 4,110 | 4,805 |

| D | 730 | 822 | 1,130 | 1,300 | 1,492 | 1,560 | 1,753 | 1,936 | 2,180 | 2,950 |

| Weight in kg | 250 | 300 | 550 | 600 | 650 | 700 | 800 | 900 | 1,000 | 5,000 |

| Net volume | 50 | 100 | 200 | 300 | 600 | 1,000 | 1,500 | 2,000 | 3,000 | 5,000 |

| Power kW | 1 | 1 | 2 | 3 | 3 | 3 | 4 | 4 | 6 | 11.0 + 0.75 |