Description

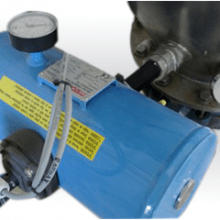

Pneumatic roller vibrator - For a very high frequency with reduced air consumption

Help with the flow of difficult products.

Pneumatic roller vibrators improve the flow of products in the hoppers via a vibration generated by a roller performing an epicyclic movement inside a steel track.

These pneumatic vibrators generate multidirectional vibrations. They are used for silo emptying, driving chutes, activating vibrating screen and vibrating table corridors and generally to clean, transport, compact and separate bulk materials and reduce friction. They are suitable for explosive or humid environments and can also work outdoors. The frequency and centrifugal force are determined by operating pressure. All our vibrators (ball, roller or turbine) comply with the Machinery Directive 89/392/EEC. The standards EN 292 have been taken into account. For activation, it is necessary to have a 2/2 solenoid valve and filtered air.

-

Efficiency4

-

Air consumption4

-

Noise level2

Equipment advantages

- Multidirectional vibrations

- No lubrication

- No maintenance

- Explosion-proof

Media

View our equipment in photos

Pneumatic roller vibrator

Roller vibrator on storage and conveying line for dissolving sugar in a weighed cast iron tank.

Pneumatic roller vibrator Palamatic Process

Roller vibrator on skid for the preparation and packing of infant milk powder.

Flow aid - Pneumatic roller vibrator

Pneumatic vibrator with roller on screening process and mechanical conveying of cereals.

Pneumatic ball vibrator

Ball vibrator on skid for powdering salt and sugar by controlled feeding of a dissolution tank and powder wetting/drying tower feeding.

Electric vibrator

Electric vibrator on metal powder preparation and dosing station.

Air cannon

The air gun on big bag emptying workshop for industrial crusher feeding.

Pneumatic hammer

Combined hammer on urea dissolution skid for Adblue manufacturing.

Aeration pad

Fluidization plate on emptying process and conveying of feed additives to storage silos.

Anti-bridging device flat bottom

Mechanical unloader with flat bottom on a discharge line and pneumatic conveying of fluorinated derivatives.

Features

Technical specification

- Multidirectional vibrations

- No lubrication

- No maintenance

- Explosion-proof

- Exercise temperature: 20 to 120° C

- Great acceleration

- 2/2 solenoid valve and filtered air required for activation

- Ex II 3D ATEX

Roller vibrators consist of an anodized aluminum body with a hardened steel roller on a cast iron track rolling inside. The vibration is generated by a roller that performs an epicyclic movement inside a steel track. These vibrators generate a very high frequency with a reduced air consumption compared to the developed force.

Dimensions :

| TYPE | A | B | C | D | E | F | IN-OUT | WEIGHT |

| mm | mm | mm | mm | mm | mm | Kg | ||

| OR 50 | 50 | 86 | 68 | 12 | 30 | 7 | 1/8" | 0,37 |

| OR 65 | 65 | 113 | 90 | 16 | 36 | 9 | 1/4" | 0,76 |

| OR 80 | 80 | 128 | 104 | 16 | 40 | 9 | 1/4" | 1,27 |

| OR 100 | 100 | 160 | 130 | 20 | 52 | 11 | 1/4" - 3/8" | 2,6 |

Performances :

| TYPE | VIBRATIONS | MAX. FORCE | AIR CONSUMPTION | ||||||

| Vpm | 2 bar | 4 bar | 6 bar | 2 bar | 4 bar | 6 bar | |||

| 2 bar | 4 bar | 6 bar | Kg | Kg | Kg | dm³/min | dm³/min | dm³/min | |

| OR 50 | 21,000 | 25,000 | 29,500 | 188 | 281 | 355 | 78 | 144 | 204 |

| OR 65 | 19,000 | 22,000 | 26,000 | 235 | 439 | 552 | 100 | 198 | 296 |

| OR 80 | 14,000 | 16,000 | 21,500 | 342 | 587 | 624 | 122 | 255 | 378 |

| OR 100 | 6,750 | 9,750 | 11,000 | 289 | 604 | 783 | 132 | 284 | 412 |

The data was collected on a spring-loaded vibrating bench to perfectly simulate most of the possible applications.

The more rigid the structure on which the vibrator is applied, the greater the frequency and centrifugal force will be.

Operating procedure:

| Technical data of pneumatic roller vibrators | ||||

|---|---|---|---|---|

| OR 50 | Characteristics of the pneumatic roller vibrator OR 50: Vibrator attachment center distance: 68 mm - Vibrator attachment Ø: 7 mm - Vibrator feed Ø: 1/8 "- Weight: 0.370 kg | |||

| Supply pressure (bar) | 2 | 4 | 6 | |

| Vibrations per minute (vpm) | 21,000 | 25,000 | 29,500 | |

| Max. centrifugal force (kg) | 188 | 281 | 355 | |

| Air consumption (dm³/min) | 78 | 144 | 204 | |

| OR 65 | Characteristics of the pneumatic roller vibrator OR 65: Vibrator attachment center distance: 90 mm - Vibrator attachment Ø: 9 mm - Vibrator feed Ø: 1/4 "- Weight: 0.760 kg | |||

| Supply pressure (bar) | 2 | 4 | 6 | |

| Vibrations per minute (vpm) | 19,000 | 22,000 | 26,000 | |

| Max. centrifugal force (kg) | 235 | 439 | 552 | |

| Air consumption (dm³/min) | 100 | 198 | 296 | |

| OR 80 | Characteristics of the pneumatic roller vibrator OR 80: Vibrator attachment center distance: 104 mm - Vibrator attachment Ø: 9 mm - Vibrator feed Ø: 1/4 "- Weight: 1.270 kg | |||

| Supply pressure (bar) | 2 | 4 | 6 | |

| Vibrations per minute (vpm) | 14,000 | 16,000 | 21,500 | |

| Max. centrifugal force (kg) | 342 | 587 | 624 | |

| Air consumption (dm³/min) | 122 | 255 | 378 | |

| OR 100 | Characteristics of the OR 100 pneumatic roller vibrator: Vibrator mounting distance: 130 mm - Vibrator attachment Ø: 11 mm - Vibrator feed Ø: 1/4 "-3/8" - Weight: 2.600 kg | |||

| Supply pressure (bar) | 2 | 4 | 6 | |

| Vibrations per minute (vpm) | 6,750 | 9,750 | 11,000 | |