Description

BULK BAG FILLING - Confined packaging for all types of super bags

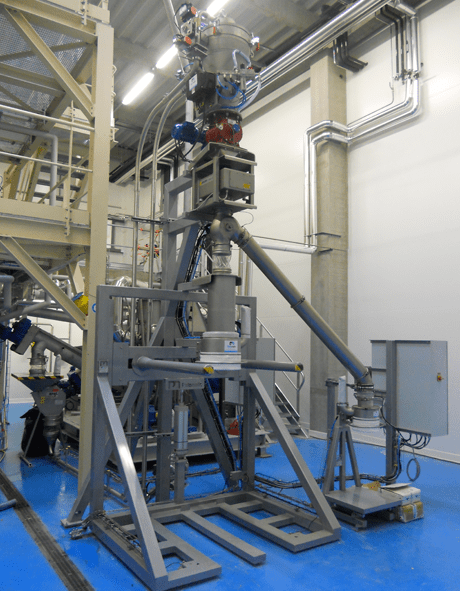

Palamatic Process designs FIBC / big bag filling and packing equipment for the loading and storing of bulk solids and powder materials. Our filling stations can be seamlessly integrated upstream or downstream of existing process lines. The FlowMatic® 01 bulk bag filling system has a loading capacity ranging from 10 to 20 big bags per hour and requires only one person for operation.

This model is a cost-effective solution for simple bulk solid packaging processes.

-

Automation1

-

Rate2

-

Overall dimensions5

Operating procedure:

1.Positioning of the big bag on the packing station

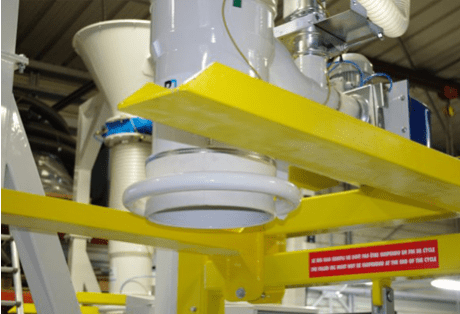

2.Airtight fixing of the big bag filling sleeve by inflatable seal

3.Big bag filling

4.Evacuation of the big bag with a forklift truck or a pallet truc, by the handling pallet or by the handles of the big bag

The airtight connection of the filling sleeve with an inflatable seal offers an airtight packaging of all types of big bags. The big bag removal can be conducted with a forklift truck or a handling pallet.

Main characteristics of the filling machine:

Palamatic Process has developed a complete range of packaging stations for big bag handling (FIBC, super sack, jumbo bag, bulk bag) to meet the needs of industries. The FlowMatic®01 model is the effective solution for the simple packaging of bulk and powdery products.

Equipment advantages

- Width adjustment capable hooks for tensioning and optimal filling of all types of big bags

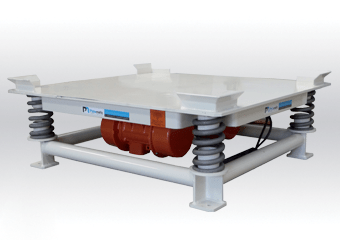

- Filling head with double casing prevents pressure build up of the big bag during packing operation

- Height adjustment of the loading hooks allows for operational flexibility

- Removal of the big bag possible with forklift or pallet truck

Media

View our equipment in videos

Bulk bag filling systems - FlowMatic® 01

Big bag filling system - Flowmatic 01

Palamatic Process has developed a complete range of packaging stations for big bag handling (FIBC, super sack, jumbo bag, bulk bag) to meet the needs of industries. The FlowMatic®01 model is the effective solution for the simple packaging of bulk and powdery products.

Bulk bag filling range

10 models of big bag filling systems

View our equipment in photos

FlowMatic® 01 - Big bag packaging

Bulk material handling equipment for big bag filling

Double station: big bag filling

Process line for filling big bag with starch

Ultrasonic probe on bulk bag filling station

Complete processing line for the management and preparation of premixes

Big bag filling: food powder processing line

Cocoa packaging line with sieving

big bag filling station

Filling with a inflatable seal ensures airtight packing of all types of big bags

Bulk bag charger FlowMatic® 03

Combined station for packing big bags and drums for the chemical industry

Big bag packaging

Process filling line of barite in big bags: FlowMatic® 01

Big bag packing Palamatic Process

Packing in big bags of white sugar and crystal sugar: big bag filling line with a capacity of 40 big bags per hour

Big bag filling

Preparation of infant milk powder

Conveyor on bulk bag filling station

Big bag filling in hygienic zone (white zone) of sugar

Double station: big bag filling

Iron hydroxide mixing and conditioning line

big bag and drum filling equipment

Filling line for packing plastic materials in drums and big bags

Filling hopper for big bag

Process line for mixing and packing phytotherapeutic materials

Big bag packaging

Industrial line for sugar processing

Through screw conveyor to feed the big bag filling machine

Trough screw for feeding the big bag filling station

Features

Technical specification

| Rate | 10 to 20 big bags/h. |

|---|---|

| Capacity | 2 tons/ big bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 0.2 kW |

| Compressed air consumption | 0.1 Nm³/h. |

| Dust removal rate | 300 m³/h. |

Finishing touches: RAL 9006, microblasted, electropolishing

Operating pressure: 6 bar

TOR input: 0

TOR output: 1

Maximum dimensions of the big bags: 1,550 (l) x 1,550 (L) x 2,400 (H) mm

U-shaped forks: enables the removal of the big bag with the forks (optional)

Equipment integrated to FLOWMATIC model 01:

- Big bag loops round hooking forks: provides easier sliding of the big bag handles.

- U-shaped forks for attaching the handles of the big bag: enables the removal of the big bag directly from the handles with a forklift truck (no use of pallets).

- Support structure: the structure is manually height adjustable so it can be adapted to any type of big bag.

- Width adjustment: the center distance of the forks is width adjustable to optimize the filling operation but provides an increased stability of the flexible container on the pallet.

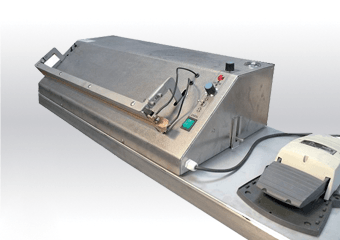

- Inflatable seal: The inflatable seal ensures an airtight connection between the filling head and the big bag during its filling.

- Filling head: the filling head is designed in a double casing for volume balancing. The charged air is evacuated through the degassing line which can be connected to the dedusting network.

1. Round forks

2. Support structure

3. Width adjustment

4. Inflatable seal

5. Filling head

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Compounding line

Processed products: plastic granules - Compounding line - Installation of a big bag and Flowbin emptying station containing powdery or granulated powders in a buffer hopper.Chemical

Preparation of dried fruit recipes

Processed products: dried fruit - Preparation of dried fruit recipes - This installation involves the feeding of dried fruit to a mixer. The various dried fruits are stored in bags, boxes and big bags...Food and Animal Feed

Spray tower for packaging feed

Processed powders: skim milk powder / whole milk powder. Client in Africa.Food and Animal Feed

Fill in the form and receive your quotation in 48h!