Description

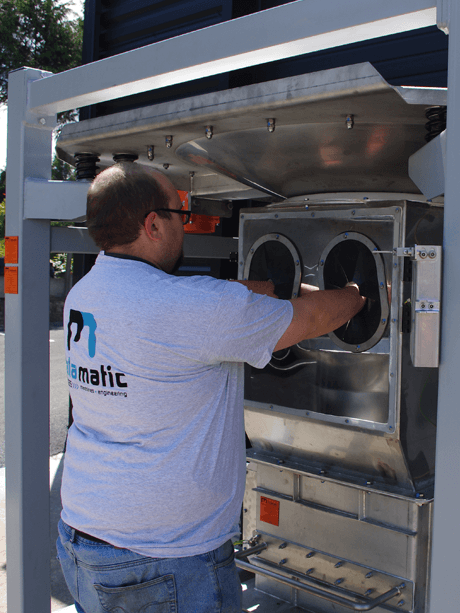

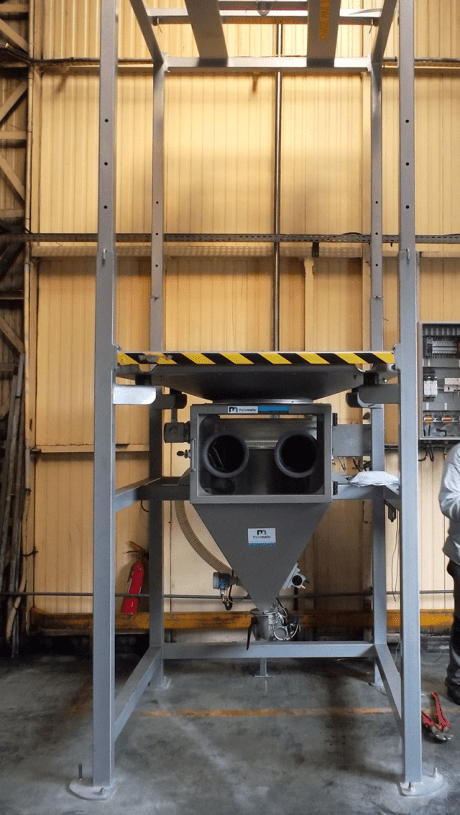

Big bag unloading station - Easyflow operator safety glove box

Total containment and operator safety

The big bag unloading station equipped with a glove box allows operators to handle toxic products without coming into contact with them. Thanks to the glove box, the operator can easily access the bun to undo it and allow the big bag to be emptied.

Rate: 10 big bags/h.

Capacity: 2 tons/big bag

Objectives: containment & flexibility of big bags

The big bags unloading station equipped with a glove box allows operators to handle toxic materials without coming into contact with them. Thanks to the glove box, the operator can easily access the bun to undo it and allow the big bag to be emptied.

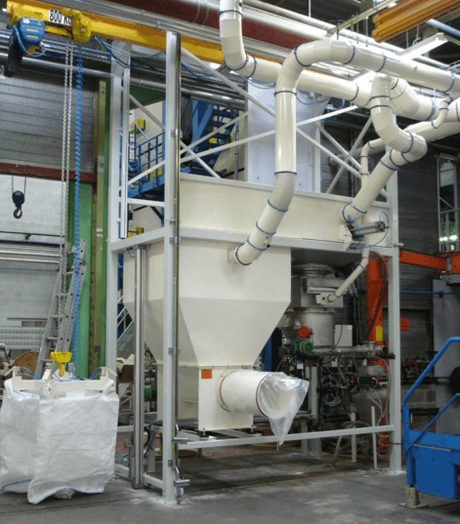

The Palamatic Process sealed big bag emptying station is the ideal solution for the handling of toxic products and contaminants. The stations can be built in painted steel, hot-dip galvanized steel, 304L stainless steel, 316L stainless steel. The installation of the big bag on the deconditioning station is ensured by you through the use of a forklift truck, an electric hoist, a low structure.

3 types of loading are possible for the handling of your big bags: loading hoist, loading trolley or low structure.

Customized big bag emptying stations: flow and containment

The Palamatic Process engineering office offers you solutions adapted to your constraints and your requirements, after a careful study of your specifications.

The Palamatic Process design office offers customized solutions according to all your operating and implementation constraints. We define the customized and adequate solution together after visiting your site and according to your precise specifications.

Built-in features :

- Automatic cutting of big bags

- Extensive containment

- Extraction of very difficult products

- Reduced implantation height

- Ergonomics of the workstation

- Compaction of empty big bags

- ATEX...

-

Rate2

-

Automation1

Equipment advantages

- Confinement and protection of the operator

- Flow control

- Flow aid

- Connection to dust removal device

Media

View our equipment in photos

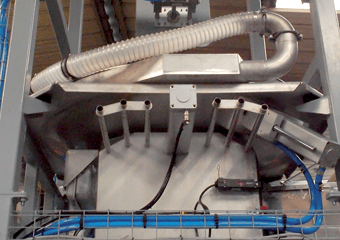

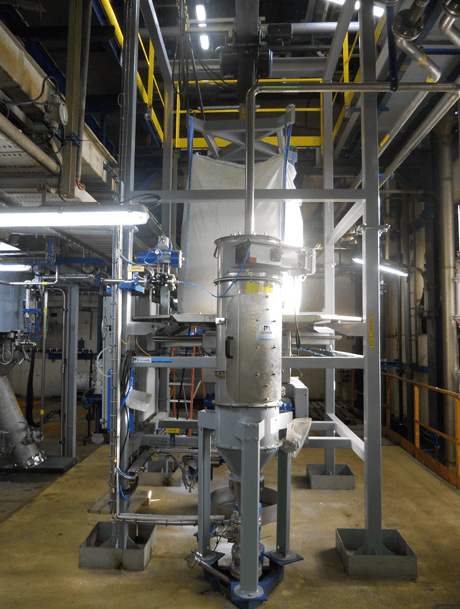

Dust tight big bag discharger

The contents of the 3 bulk bag unloading systems are reconditioned in stainless steel containers.

Big bag discharging - Glove box

Liquid formulation:

- 3 big bag dischargers for 7 types of bulk materials.

- 3 re-packing and un-packing stations for stainless steel containers.

- 2 pneumatic conveyors feeding 2 reactors.

Bulk bag discharging - Glove box

The customer's requirements for this process specifically relate to containment during deconditioning.

Jumbo bag - Dust containment enclosure

The dust containment enclosure prevents the operator from coming into contact with the discharged bulk material while maintaining a good visibility.

Big bag discharger glove box

This installation includes 3 big bag discharging stations for 7 types of materials

Big bag discharging system - Glove box

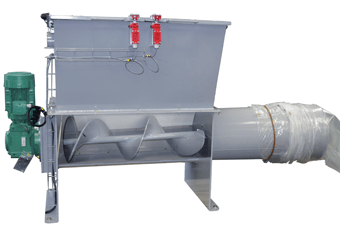

Big bag discharging system - Glove box. Electric hoist loading. A big bag compactor is integrated into the emptying system.

Industrial dust collection powder handling

This machine is designed for the manual opening of all types of big bags, limiting dust emissions as much as possible and facilitating the flow of the bulk material. The big bag is installed using an electric hoist.

Big bag unloader

The dust containment enclosure with its dust-tight door provides safe and ergonomic access to the big bag discharge spout.

Features

Technical specification

| Rate | 10 big bags/h. |

|---|---|

| Manufacturing materials | Painted steel, 304L stainless steel, 306L |

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Installed power | 0.1 kW (depending on option) |

| Compressed air consumption | |

| Operating pressure | 6 bar |

| Required dust removal rate | 1,000 m³/h. |

| Maximum size of big bags (length x width x height) | 1,200 * 1,200 * 2,400 mm |

| Entrance | |

| TOR input | Depending on the option |

| TOR output |

Depending on the option |

Integrated systems:

- Low structure

- Lump breaker (optional)

- Connecting tube

- Big bag/glove box

- Vibrating motor

- Big bag removal tray

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Gelatin for capsules

Processed materials: pork gelatin, fish gelatin, bovine gelatin, for capsules coating gelatin for capsules - Gelatin for capsules - This company acting in the pharmaceutical sector is one of the world...Fine chemical

Black mass treatment process

Treated powder: black mass - Black mass treatment process - Process to unload the black mass from bulk bags, precisely dose and repulp it with water, without clogging reactions or dust emissions from...Energy

Bucket filling line

Material: Graphite - Bucket filling line - Turnkey solution for bulk bag emptying, total containment and rapid filling of buckets with graphite powder.Chemical