Processed powders: Cement + filler, lime and calcium nitrate

Cementation of nuclear waste

This process is intended for the cementation of fines and resins. It is divided into 5 phases.

- Phase 1: deconditioning of big bags for cement and filler supply to the process

- Phase 2: conveying and mixing of cement and filler

- Phase 3: conveying of powders (cement, filler) after their preparation to the dosing hopper.

- Phase 4: preparation of the batches by the dosing hopper (on load cells)

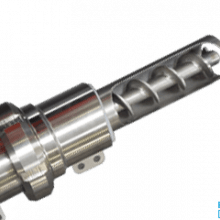

- Phase 5: conveying of the preparation to the receiving drum via two conveying screws. The second screw is of specific design since it is the link between zone 3 and zone 4. In order to achieve a perfectly tight connection, the screw is sealed in the concrete. Its design is an Easyclean design with specific tool conception, allowing maintenance acts to be carried out using a robot (contaminated area).

The loading equipment upstream of the process is a big bag emptying system.

This big bag emptying station is designed for manual opening of big bags, minimizing dust emissions and facilitating product flow. The big bag is placed using an electric hoist. The big bag emptying station is fitted with an unlacing cabinet with a tight door that provides safe and ergonomic access to the big bag emptying cuff.

A knife-type lump breaker is used at the outlet of the big bag deconditioning station. The lump breaker is the ideal solution for crushing materials that tend to form blocks. The industrial lump breaker is used to break blocks that are formed during the production or shipping process of friable powder materials.

The lump breaker integrates 2 spindle shafts; the rapid rotation of special knives through a fixed grid makes the blocks crumble. Also, the presence of two rotors provides high flow rates.

A receiving hopper is located underneath the lump breaker. It is fitted with a high level probe allowing the lump breaker to stop when the high level is detected. When the probe is uncovered, the lump breaker restarts.

A VFlow® vacuum conveying system with detached filtration operates at a flow rate of 3 t./h. This system consists of a cyclone separator without filter and a cyclofilter for completion. Both equipment are located on the mixer's supply flanges, allowing it to operate in a closed cycle (no product loss). The conveying line is connected under the lump breaker via a gearbox.

The horizontal ribbon mixer has a capacity of 1,100 liters. This industrial belt mixer allows the mixing of the cement + filler batch.

The mixer is provided with an automatic piston sampler with a collecting pot.

At the outlet of the belt mixer, a 4-meter long vibrating steel conveyor channels the powder from the ploughshare mixer to the weighed dosing hopper. Due to the fluidity of the material at the mixer outlet, a 4-20 mA butterfly valve supplies the vibrating conveyor in a controlled manner.

The dosing hopper is mounted on 3 load cells; it allows to inform the supervision on the dose being processed.

The dose is performed using the "4-20 mA butterfly valve and vibrating conveying assembly". At the outlet of the vibrating conveyor, a pinch valve switches off the product flow when the target weight is reached.

A degassing filter is installed on this hopper. It ensures the balancing of volumes. During the discharge phase of the dosing hopper, a flow aid kit facilitates the complete discharging of the dose. It consists of fluidization nozzles and pneumatic vibrators.

A tubular conveying screw is used to convey the powder from the dosing hopper to the easyclean conveying screw.

This easyclean conveying screw makes the connection between the 2 rooms in a tight and secure way. The part of the screw connecting the 2 zones is embedded in the concrete mold of the conditioning room.

All maintenance work is performed in zone 4 (radiation zone) thanks to a quick dismantling system that can be manipulated by robot.

A control cabinet completes the installation.