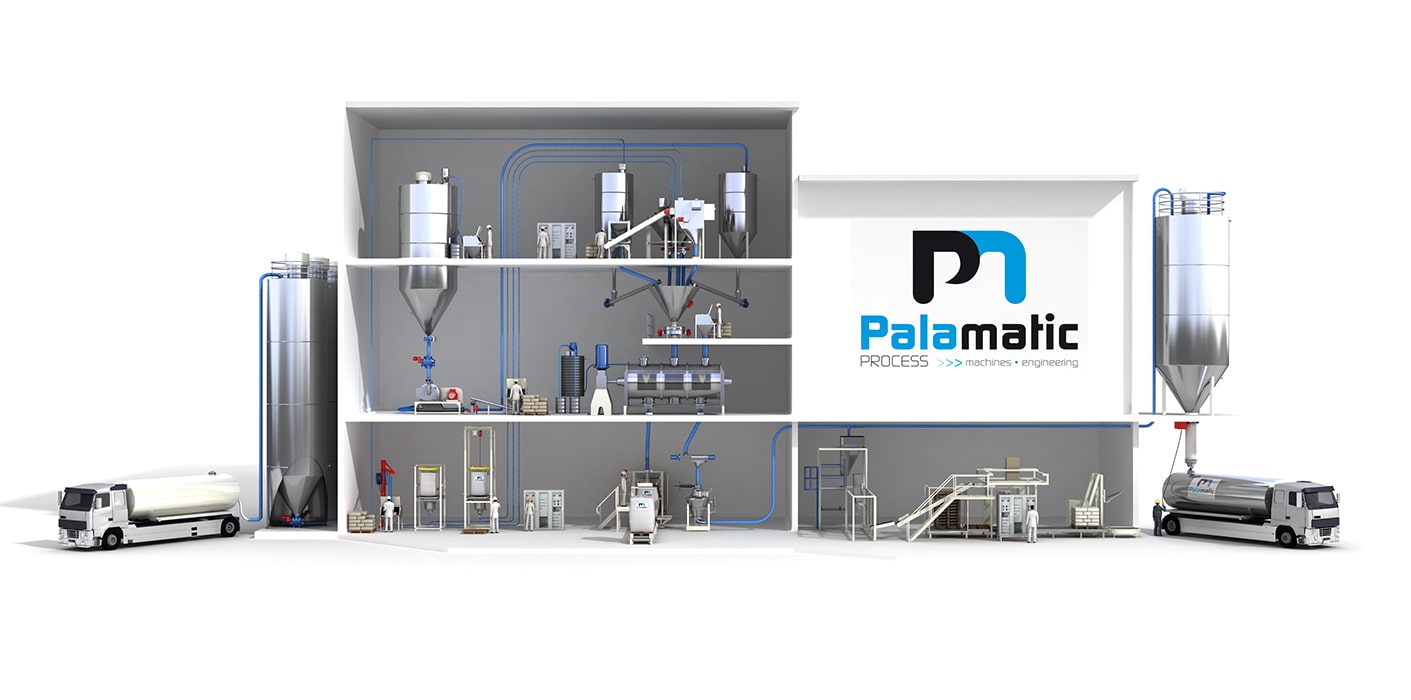

Palamatic Process Inc is an original equipment manufacturer and systems integrator for all bulk material handling and powder process industries.

Since 1992, Palamatic Process has been a bulk material handling equipment specialist in the sectors of food & beverage, chemical, pharmaceutical, environmental & mineral, nuclear and water treatment industries. We offer turnkey solutions for the handling of all powders and bulk solid materials.

Examples of our product offering include:

- Bulk Bag Filling Stations - manual to fully automated systems

- Bulk Bag Discharge Stations - manual to fully automated systems

- Bag Dump or Sack Tip Trays

- Pneumatic Conveying Systems - dilute and dense phase

- Centrifugal Sifters and Vibratory Sieves

- Industrial Pin Mills

- Powder Mixing and Blending Equipment - ribbon, plow, batch or continuous, etc.

- and much more ...

- Since 1992

- Installations 2500

- Countries 50

- 6 industries

of activity

Palamatic Process is a "solutions-oriented" equipment supplier, specializing in custom design and implementation of bulk material manufacturing lines around the world. Our staff can provide a wide range of bulk material handling equipment to fill, discharge, convey, pre-break, mill, sieve, dose, mix, store, pack, control and automate. With 28 years of experience, Palamatic Process' highly skilled engineers can provide optimal solutions with both "standard" and "custom-made" equipment processes. With our location in Philadelphia PA, we continue to grow and expand our solution based services and availability to the North American markets.

We look forward to servicing the needs of our client's production requirements!

Products

Bulk and Powder Handling Equipment

Palamatic Process designs, manufactures and integrates bulk material and powder handling equipment, including automated process lines.

We supply equipment for handling your big bags, sacks and drums, as well as pneumatic and mechanical conveying systems, industrial crushers, mills and dosing mechanisms.

Our engineers have the required experience in bulk and powder processing for various industries including; food & feed, chemical, pharmaceutical, environmental, nuclear and water treatment.

Our Customers

Our customers operate in a wide variety of industries and our engineers have the required experience to plan and supply your process with cost effective and efficient equipment.

Test Center

The state of the art test center at Palamatic Process is suited for all of our industrial customers. We are capable of providing the necessary data to prove production line concepts in bulk material handling.

Augmented Reality

Download the Palamatic Process 3D application on your smartphone and visualize your future equipment in augmented reality!

News

News

Join Palamatic Process!

Palamatic Process is recruiting

Our employees share the same values of integrity, respect, service, quality and teamwork in order to suceed together.

Thanks to the commitment and skills of our team, we are constantly improving and innovating within our company. Everyone here plays an important role by contributing to the overall performance of Palamatic Process and the future of our success.

Palamatic Process Inc. is capable of custom-engineered process solutions including stand alone equipment, turn key integration, and fully automated bulk material handling equipment and powder processing systems that can mostly utilize our company’s original equipment.

Filling: bulk bag filling equipment, super sack filler, bag filler, bulk bag filler, bulk bag filling system, automatic FIBC filling, wash down bulk bag fillers, high rate FIBC filling, automated bulk bag filling, mobile bulk bag filling station, pharmaceutical clean room bulk bag filling sytem, bag compactor, super sac

Discharge/Unloading: super sack unloader, bulk bag unloading, bulk bag tie box, bulk bag glove box, high rate bulk bag discharge, sack discharge station, dual bulk bag and sack tip, bag tipping, bag dump station, sack tip, contained bag dump station, sack tip tray, bag dump screening equipment, bag dump with sack compactor, automated bag dump station, high speed bag dump equipment, bag manipulator, ibc discharge system

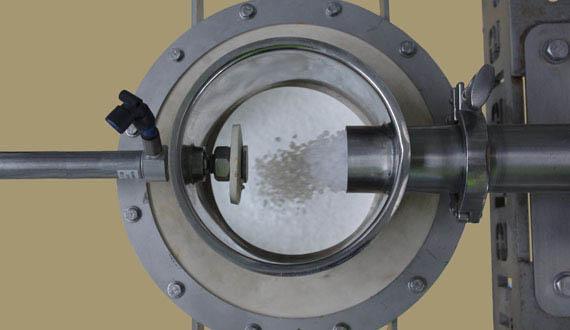

Powder/Bulk Material Conveying: vacuum conveyor, vacuum system transfer for powders, lean phase conveying, dilute phase conveying, dense phase conveying, dense phase pneumatic conveying, screw conveyor

Mixing: ribbon mixers, plow mixers, single mixers, paddle mixers, slurry mixer, continuous blender, vertical ribbon mixer, conical screw blender

Screening: vibratory screen separator, inline pneumatic screening, centrifugal sifter, rotary sifter, inline conveying screeners

Size Reduction: mill grinders, deagglomeration, delumper, kibbler, industrial lump breaker, pre-mill crusher, pin mill, universal mill