Barrel dischager:

The Drumflow® range allows the handling of your powders from barrels (plastic or metal). Our equipment can easily lift, turn, discharge and transport different types of barrels.

Your powders and bulk products are unpacked manually or automatically using a barrel tipper, forklift or stacker.

The DrumFlow® Palamatic Process range allows the drum to be emptied by turning it over with a capacity ranging from 180 kg to 250 kg and offering an easy grip on the tipper.

Drum discharging system - DrumFlow®03

-

Rate4

-

Containment5

Drum discharging system - DrumFlow® 04

-

Rate1

-

Containment5

Drum tipper - DrumFlow® Liquid

-

Rate4

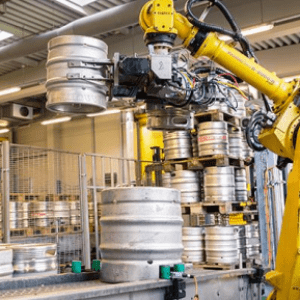

DrumBot 100 – Depalletization, Automated Opening and Emptying of Drums

-

Efficiency5

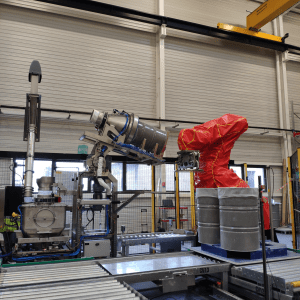

Jumbot 1000 – Automated Big Bag Discharge | High-Performance Industrial Unpacking Robot

-

Efficiency5

Drum manipulator - Barrel handling

-

Ergonomics5

-

Ease of implementation4

The Palamatic Process DrumFlow® range is designed to discharge your dry ingredients stored in barrels.

Our barrel tippers are available in 4 models:

- Barrel unloader DrumFlow® 01 suction pipe

- Barre unloader DrumFlow® 02: bag extraction

- Barre tipper DrumFlow® 03: tipping

- Barre unloader DrumFlow® 04: sealed tipping

You don't know which barrel tipper to choose for your industrial process? Palamatic answers you!

The Palamatic Process engineering office can provide customized solutions for discharging your barrels (sealed or open-chute dumping) according to your production line requirements. We define the appropriate customized barrel unloading solution after visiting your site and following your precise specifications. Design options can allow the operator to fully or partially unload the contents of the drum into hoppers, reactors or mixer inlets.

Palamatic Process also offers complete turnkey process solutions for emptying and transporting metal or steel barrels. One example is the DrumMatic® automatic barrel unpacking unit, equipped with an easy-to-grip tipper and a 5-axis robot. This process line ensures optimum operator safety, a capacity ranging from 15 barrels/hr to 60 barrels/hr depending on the DrumFlow® equipment chosen, as well as respect for the final products