Our industrial powder mixing machines and blending equipment are designed to meet the requirements of industries in all sectors of activity. Our powder mixing machines include: monorotor batch belt mixer, biorotor batch pellet mixer, vertical mixer, sanitary ribbon blenders, etc.

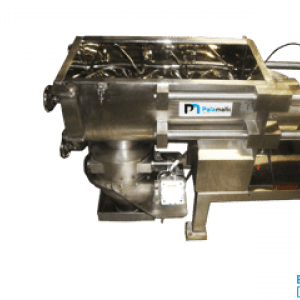

Our vertical ribbon blender is ideal for food and pharmaceutical mixing and blending due to its hygienic design and functionality. This industrial mixing equipment offers high quality mixing of powders and bulk materials. The Plow and blade mixers available offer fast batch mixing and consistent reproducibility between batch runs.

Palamatic Process industrial agitators enable the homogenization of your powders and bulk materials. They can be integrated at multiple stages within a factory production line. Several important criteria influence the choice of the appropriate mixer:

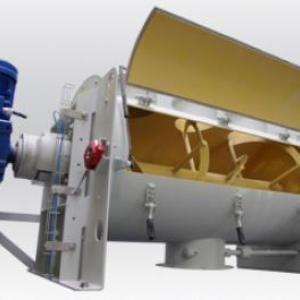

Industrial paddle mixers create a much more intense mix than ribbon mixers. The paddles introduce significant amounts of air into the mix, fluidizing the particle bed in the tank and facilitating particle movement. This results in shorter mixing times compared to ribbon mixers.

Ribbon mixers are better suited for fragile and delicate products, particularly for food or animal powders.

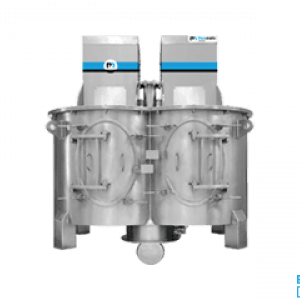

Container mixers provide homogeneous, fast, and simple mixing of powders, featuring secure container locking mechanisms.

Paddle mixers are ideal for homogenizing and mixing two or more dry or wet materials and can also transport materials during the mixing process.

For more information, consult our article: What are the different types of industrial mixers?

Certain industries, such as food, pharmaceutical, and cosmetics, require strict hygiene and cleanliness standards to prevent contamination or pollution of final products. To meet these standards, cleaning solutions are integrated into the mixers.

The vertical food-grade industrial mixer is perfect for mixing food powders. This mixer delivers high-quality mixing for powders and bulk materials while complying with hygiene standards in the food industry.

An Easy Clean hygienic mixer model with an extractable shaft is also available. This design facilitates operator access to various parts of the mixer, ensuring frequent and thorough cleaning. See our article: How do I clean my industrial mixing line?

Palamatic Process has developed ready-to-use mixing systems to address production challenges in various industries (bakery and pastry, spices and flavorings, prepared foods, pharmaceuticals):

The Palamatic engineering team is available to assist you with your project.

An industrial powder mixer is a machine designed to uniformly mix different powders or granules to produce a finished product that meets specific requirements.

There are four main types of mixers, each suited to specific powders and industrial applications:

Each piece of equipment is designed to integrate seamlessly into specific production lines, offering options for cleaning, dust control, or containment.

Industrial mixers are widely used in the following sectors:

Palamatic Process solutions are designed to meet the specific needs of each sector, offering high-performance equipment that complies with quality and safety standards.