Palamatic Process offers complete industrial solutions for sugar and chocolate confectionery processes.

From raw material management to finished products, our turnkey formulation lines produce high quality batches with assured traceability.

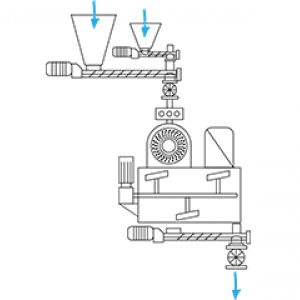

The chocolate process consists of grinding cocoa beans to produce the cocoa mass. Chocolate is a mixture of cocoa powder, sugar, cocoa butter and milk (or a dairy alternative). The cocoa mass is mixed with the other raw materials (sugar, milk, etc.) in a mixer. This step is called blending: the other raw materials are added and are mixed for about 20 hours to obtain a homogeneous paste.

The next stage is the tempering and coating process. In order to obtain a brittle and smooth chocolate it is necessary to temper it (i.e., maintaining the temperature at 32°C) in order to carry out the molding and coating. The chocolate is then ready to be tasted!

When it comes to the industry of chocolate and confectionery, production focuses on mixing, batch preparation and filling operations, via a high processing capacity and automation. Preparing batches with the exact doses of raw materials is an essential part of producing chocolate and confectionery.