Palamatic Process can satisfy the needs of industrial production plants and industrial bread and pastry production lines.

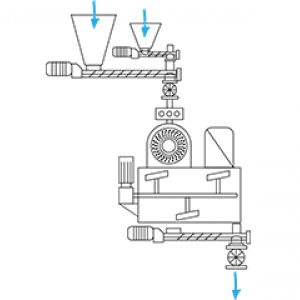

Experts in the design of pneumatic conveying systems, we are able to supply and install various elements necessary and/or complementary to its proper functioning: cyclones, intermediate tanks, solid distributors, super sack emptying stations, bag compactors and more!

The manufacturing process of bread making on an industrial bakery scale includes the following steps: storage and dosing of ingredients (flour, sugar, chocolate, etc.) in bags, tanks or silos, kneading (dosing of recipe ingredients, mixer loading), extrusion line for the shaping of dough pieces, proofing-fermentation (thanks to the integration of yeast), scarification, oven-baking, cooling, freezing, packing and storage / shipment.

From the supply of the flour storage silo to the control of the ingredient dosing, batch or continuous, through the yeast stirring tanks and sieves for quality control, we offer a turnkey installation for your industrial bakery production line.