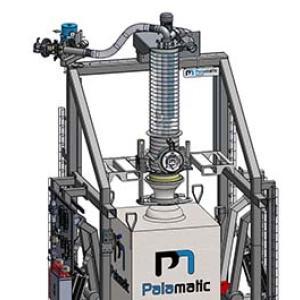

Palamatic Process has developed a wide range of bulk bag emptying stations, including EasyFlow® and Duopal® models, for handling your powders and powders.

Our super sack discharger systems are designed to meet the requirements of different types of deconditioning. They are frequently used for installations requiring slaked lime, activated carbon or polymer dosing.

Bulk bags can be loaded in a number of ways: electric hoist, forklift truck, low structure using an overhead crane.

Our bulk bag unloading systems are designed with the flexibility to meet the requirements of any bulk solids and powder processing operation. The bulk bag dischargers are frequently used in installations requiring the metering of hydrated lime, activated carbon and polymers.

Our FIBC discharging units also operate on various raw bulk materials such as plaster, cement, flour, milk powder, sugar, clay, plastic granules, pigments, chalk, gluten, urea, PVC resin, starch, grains, salt, etc.

The bulk bag discharging station is designed to contain dust and prevent product cross contamination. The super sack discharging can be conducted with both material security and hygienic design in mind.

The bulk bag discharger can be built in painted steel, hot-dip galvanized steel, 304L stainless steel or 316L stainless steel. The parts in contact with the bulk material and the structure can be made of different materials.

Further options are available for our bulk bag unloader machines depending on the needs of the operation such as bag massage system, vibrating hopper, load cells, etc.

The EasyFlow® EF0 standard bulk bag unloading model with tie-off box is designed for the ergonomic unpacking of bulk bags and to facilitate their handling.

The EasyFlow® EF1 bulk bag unloading station structure with a telescopic tube is ideal for ensuring a completely sealed unloading process and smooth powder flow.

The EasyFlow® EF2 unit, equipped with a glove box, allows safe handling of toxic products by the operator through total containment.

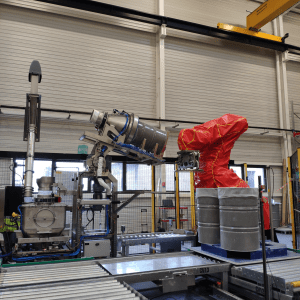

The EasyFlow® 100-200 station autonomously performs cutting, handling, and evacuation phases for bulk bags.

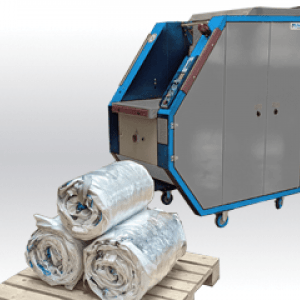

The EasyFlow® EF500 is a high-speed automatic bulk bag emptying system that operates without operator intervention. This station features a bulk bag gripper, also known as a hydraulic clamp, mounted on an overhead crane. It ensures smooth movement over the discharge hoppers. The bulk bag is then automatically released to a bag compactor or a baling press.

For partial, multi-product emptying with an integrated weighing device, the EasyFlow® bulk bag unloading Flex station is the most suitable. It includes a retractable suction wand that allows for the evacuation of a partially used super sack.

Palamatic Process also offers the Duopal® range for bulk bag handling and sack emptying. This range includes various models with a tie-off box (Duopal® DP0), telescopic tube (Duopal® DP1), or glove box (Duopal® DP2), depending on your process requirements and constraints.

The Duopal® bulk bag and sack station provides a bulk bag unloader system that operates via electric hoist, forklift, or overhead crane and is available in a low-profile structure. This bulk bag unloading station can offer containment and operate under NFPA-rated atmospheres for treated powders. The equipment in this range ensures complete sealing during product unloading and provides ergonomic operation for the user.

This bulk bag unloading system helps prevent dust emissions and product contamination. Raw material unloading is performed with maximum safety and hygiene. The bulk bag unloading station can also be equipped with a sack emptying system, massage unit, commercial dosing and weighing system, or vibrating hopper.

Bulk bag stands are essential for the safe handling and storage of bulk bags, ensuring the stability and security of the bags and reducing the risk of tipping and spillage. They often come with safety features such as retaining straps and non-slip bases, guaranteeing safe and efficient handling.

On the production lines, the bulk bag discharger is generally associated with systems of:

Palamatic Process Inc. is equipped with a state-of-the-art test facility and can carry out full-scale tests for super sack unloading, bulk bag dumping, and super sack discharging concepts. These tests can be combined with a pneumatic or mechanical conveying system, volumetric or weight dosing systems, and dust control filtration.

Our design office is at your disposal to review your process constraints and offer personalized handling solutions tailored to the powders you handle and your industry.

Palamatic Process bulk bag unloading systems are adaptable to all industries: food processing, chemical, fine chemicals, construction, water and flue gas treatment and nuclear.

Powder handling is feasible in all these sectors, including when dealing with explosive (ATEX-rated) powders.

If your powder has poor flow characteristics, a bulk bag massage cage can be integrated into your setup. Discover the three key benefits of using a bulk bag crusher.

Our project managers can also conduct studies for investment plans aimed at improving industrial efficiency and debottlenecking your site to optimize your product manufacturing.

Bulk bags emptying stations offer many advantages, particularly in terms of safety, versatility and efficiency. They minimize the risk of spillage and tippings, are adaptable to various materials and applications, and enable rapid and efficient transfer of materials.

Compliant with safety and environmental regulations, they reduce waste, improve product quality and can be automated for complete emptying. In addition, they are flexible, easily integrated into existing installations and are reliable, requiring little maintenance.

Choosing the right bulk bags emptying station depends on several important factors, such as the nature of the product (physical characteristics, properties, dangerousness), production constraints (emptying rate, volume, integration), the working environment (available space, ATEX conditions, hygiene standards), ergonomics and safety (handling frequency, weight of bulk bags, level of automation), specific options (massage system, total containment, traceability) and budget (initial cost, productivity gains, maintenance costs).

Bulk bag emptying stations can be compatible with NFPA environments (explosive atmospheres) thanks to appropriate design and equipment. Manufacturers offer NFPA versions incorporating safety features such as grounding, anti-static materials, certified electrical components and containment systems. It is crucial to use suitable bulk bags, such as types C or D. Consult experts to ensure the equipment meets the required safety standards. By following these precautions, bulk bag emptying stations can operate safely in ATEX environments.