Description

BULK BAGS AND SACKS UNLOADING COMBINED STATION - TELESCOPIC TUBE FOR MAXIMUM CONTAINMENT

Rate: 10 to 20 bulk bags/h - 180 bags/h

Capacity: 2 tons/bulk bag

Objectives: Total containment and flexibility of bulk solid FIBC discharge

The combination super sack and bags unloading station ensures dust-free discharge and keeps the spout under tension to aid the flow of the stored powder. The design of this equipment also promotes worker safety during operation. Three designs are available: hoist loading, forklift loading or low structure.

Operating Sequence:

1. Loading of the bulk bag or super sack

2. Positioning of the bulk bag spout onto the telescopic tube

3. Secure the spout using the bulk bag clamp

4. Opening / unlacing the spout sleeve

5. Flow of the product and total dust containment

Palamatic Process’ design and engineering office can also offer our customers customized solutions according to your process requirements.

-

Rate2

-

Automation1

Equipment advantages

- Connection tube: airtight connection between the bulk bag and the unloading station.

- Containment tube: ensures containment of the bulk solid flow during unlacing and discharge while maintaining complete operator safety.

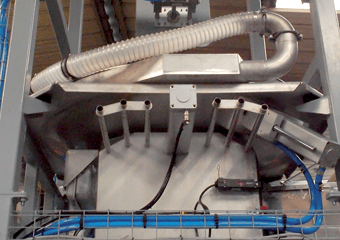

- Deposit tray massage: the flow of the product is aided by the installation of a pneumatic massage system.

- Multi-container deconditioning: the opening of the unloading station allows the deconditioning of different types of containers, bags, cartons, etc.

Media

View our equipment in photos

Big bag discharching - Hoist loading

Bulk bag discharger: dust-free loading

Big bag & sack discharging - Telescopic tube

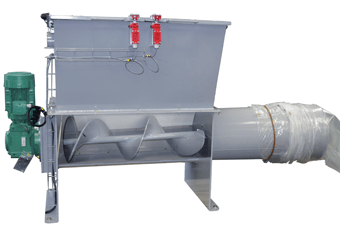

The Duopal® allows automatic discharging from bulk bags as well as manual emptying from sacks, drums and other containers.

Sack manual discharging

Discover the Palamatic Process test center entirely dedicated to the handling of your raw ingredients and bulk materials.

Containment big bag discharging

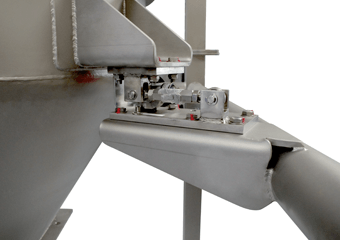

The pneumatic cylinder provides total containment. The operator can adjust the connection height according to the size of the big bag handled.

Big bag unloading

Big bag & sack discharger with telescopic tube and sealing with clamp.

Bulk bag unloading - Telescopic tube

The pneumatic cylinder provides total containment. The operator can adjust the connection height according to the size of the big bag handled.

Iris valve

Flow control valve as an option. This pneumatic valve is used to throttle the big bag spout.

Jumbo bag discharging

Vacuuming of the big bag: the operator can vacuum the big bag through the dust collector to avoid dust emission.

Double big bag emptying station

Double big bag and sack discharger, loading by lifting truck.

Big bag discharger

Big bag discharger with dust containment enclosure with tubular screw for bulk materials conveying.

Sack discharging - Food powder

Sack an big bag discharger on for raw ingredients and bulk materials handling.

Pharmaceutical industry

Installation for discharging sacks and big bags for a pharmaceutical application.

FIBC and sack discharger

Big bag & sack discharger with telescopic tube and sealing with clamp.

Features

Technical specification

| Rate | 10 to 30 bulk bag/h - 180 sacks |

|---|---|

| Capacity | 2 tons/ bulk bag |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 0.1 kW (depending on option) |

Integrated equipment:

- Handling cross

- Support structure

- Pneumatic cylinders for massage system

- Bulk bag deposit tray

- Unlacing box with airtight door

- Hoist remote control

- Containment tube to prevent overflow

- Bag compactor

- Bag dump station

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Production of veterinary medicinal products

Processed powder: pharmaceutical powder - Powdered veterinary medicinal substance - The process consists of emptying powders to feed a bagging machine.Fine chemical

Spray tower for packaging feed

Processed powders: skim milk powder / whole milk powder. Client in Africa.Food and Animal Feed

Process for mixing dry ingredients

Processed Materials: Granulated Sugar, Rebaudioside M, Cocoa Powder and various minor ingredients - Process for mixing dry ingredients - The new facility expansion project required the capabilities of...Food and Animal Feed

HAZLOC Rated Industrial Equipment for Feeding a Solvent Reactor

Treated powder: Titanium dioxide (TiO2) - Feeding of a solvent reactor in the inks and coatings sector - Emptying station for big bags and sacks with powder transfer system by a tubular screw.Chemical

Manufacture of aperitif biscuits

Processed powders: pumpkin seeds, linseed, sesame seeds, corn starch - New installation for the manufacture of biscuits and crackers - Emptying of big bags to feed a mixerFood and Animal Feed