Description

BULK BAG BALERS REDUCE THE VOLUME OF SPENT FIBC’S FOR A HEALTHY AND DUST FREE ATMOSPHERE

The Palamatic Process CBB125 bulk bag compactor can be made either of painted carbon steel, 304 or 316 stainless steel for food and pharmaceutical applications.

In order to save space and minimize waste volume, our bulk bag compactors collect and compress all types of flexible containers (paper, polyethylene, braided plastic, etc.) contained within a polyurethane sheath. The standard design also helps contain residual dust via a tapping connection to central dust system, or an integrated filtration unit for a 100% dust free atmosphere.

Discover our white paper on the subject: What should you do with your used big bags?

-

Containment5

-

Ease of implementation3

Equipment advantages

- Suitable for all types of flexible containers

- Clean work environment

- Can be supplied alone or integrated into a bulk bag unloading station

- Possible to recover residual fines through custom design

Media

View our equipment in videos

Big bag compactor

Big bag compactor

View our equipment in photos

Bulk bag compactor by Palamatic Process Inc.

Machine intended for compaction and containment of all types of bulk bags.

Bulk bag compactor

Big bag compactor with a 100% dust-tight polyethylene sheath to keep the working environment clean.

Empty big bag industrial compactor

Ergonomic loading of the big bag into the compactor.

Big bag compactor

Effective, with a compact design, the compactor is suitable for all types of big bags, eliminating the majority of dust through the installation of a connection to the dedusting network.

Jumbo bag compactor

Containment and management of empty big bags.

Big bag & sack compactor

Reduce the volume of waste and maintain a dust-free, healthy atmosphere.

Big bag compactor Palamatic Process

Tension ring and dust-tight compaction sheath.

Big bag

Bulk solid materials, raw materials, bulk solids storage solutions.

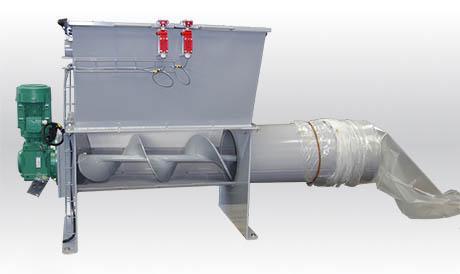

Compactor screw

The screw may only be operated with the door closed.

Big bag compacting screw

Trough screw in stainless steel 304L or stainless steel 316L.

Bulk bag

The bulk bags are introduced into the compactor to compress them.

Independent big bag compactor

The bulk bag compactor can be directly integrated into the big bag discharge station. It is also available as an independant system.

Reduce waste volume

Processing of empty packaging directly at the workstation.

Big bag compactor sheath

Significant reduction in waste disposal costs.

Industrial big bag compactor

Bulk bag compactors are designed for compacting all types of big bags, while eliminating most of the dust.

Independent bulk bag compactor

Bulk bag compactors collect and compress all types of big bags.

Compactor for empty big bag

100% tight containment sheath.

Big bag industrial compactor

Empty bulk bag screw compaction.

Big bag compactor

The big bag compactor reduces the volume of waste without dust emissions.

Big bag compacting screw

Stainless steel 304L or 316L stainless steel compaction steel coil.

Jumbo bag compactor Palamatic Process

Big bag compactor with a polyethylene sheath to collect empty big bags.

Polyethylene sheath industrial compactor

Support tube for the 100% dust-tight polyethylene sheath.

Screw compactor for jumbo bag

Trough screw on big bag compactor.

Big bag compactor

FAT of a big bag compactor for shipment to the United States.

Compacted big bag

Containment and management of empty big bags.

Waste reduction

Reduce the volume of waste and maintain a healthy dust-free atmosphere. In addition, the integrated compactor keeps the product in a closed area until the big bags are compacted.

Big bag compactor in a closed area

It prevents the operator from dispersing the product during the manual removal of the big bags.

Features

Technical specification

- The empty big bag compactor is composed of a surface-treated trough with steel, 304L stainless steel or 316L stainless steel.

- The compactor is equipped with a direct drive.

- A polyethylene sheath tube positioned at the end of the compaction tube allows the empty big bags to be collected.

Dimensions :

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Bulk pigment handling

Processed powders: zinc ash, zinc oxide, waelz oxide - Bulk pigment handling - The materials to be unloaded are powders whose particularity is to have very heterogeneous characteristics.Chemical

Supply for battery manufacturing

Processed powder: cadmium oxide - Supply for battery manufacturing - The objective of this installation is to protect operators by avoiding the constraint of hazmat suits, which is poorly accepted by...Chemical

Dosing in a cutter mincer mixer

Processed powder: starch - Dosing in a cutter mincer mixer - The process is designed to feed a shredder in a controlled way. It consists of an EasyFlow® EF big bag deconditioning system, a VFlow®...Food and Animal Feed

Double confined EasyFlow® EF200 bulk bag emptying station

Products processed: solid coal rods - Double confined EasyFlow® EF200 bulk bag emptying station - The installation concerns two bulk bag unloading stations for high-speed, semi-automatic...Minerals and building

Cement truck filling

Processed product: cement - Filling of truck with cement - Two EasyFlow® EF100 bulk bag unloading stations for high-speed semi-automatic unpacking .Minerals and building

Reduction of bulk bag waste and elimination of dust

Products processed: herbicides, fungicides, biosolutions - Compacting of bulk bags - Dust removalChemical

Cement unloading and conveying

Processed powder: cement - Unloading and conveying of cement - Unloading of cement from 1 ton bulk bags with pneumatic transfer of material to silo storageMinerals and building

High-rate bulk bag unloading system for the plastics and polymer industry

Processed powders: PET resin granules and PET flakes - Fully automated big bag discharging line - Big bag compaction at the end of the lineInsect breeding

Economical industrial solution for the packing of 1-ton super sacks for the containment of dust fumes

Processed powder: zirconium - Big bag packaging line below the dryer - Dust containment - Big bag compactor with screw conveyor.Chemical

Cement deconditioning

Processed product: cement - Cement deconditioning - Autonomous bulk bag unloading system for the cement industryMinerals and building

Optimizing Bulk Bag Discharge with BFM® Fitting Connections

Powders Processed: Pharmaceutical excipients and food ingredients - Optimizing Bulk Bag Discharge with BFM® Fitting Connections - Bulk Bag Discharge Solution with BFM® Fitting ConnectionsFood and Animal Feed

Secure and Optimize the Handling of Sensitive Powders in Industry

Powders handled:lithium, Lithium, NMC compounds (Nickel, Manganese, Cobalt), and anode/cathode materials (graphite, LiFePO4), requiring secure handling due to their toxicity, hygroscopic properties...Chemical