Description

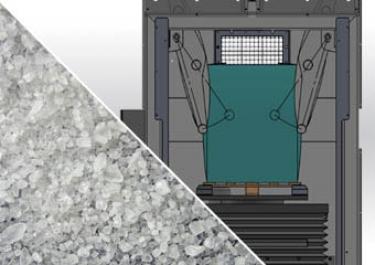

BULK BAG CRUSHER - PREPARATION OF BULK SOLIDS PRIOR TO EMPTYING

The bulk bag conditioner prepares bulk bags before emptying. Once in the safety cage, the bulk bag is massaged by several pairs of cylinders (up to 8 pairs/16 jacks depending on final design). Offered with either pneumatic or hydraulic cylinders, these mechanisms break up the condensed mass in the bulk bag that can occur during storage to facilitate quick material discharge. Several massage options are available depending on the material load to facilitate the entire volume of the bulk bag is processed. The screened enclosure ensures worker safety during operation of the installation.

Equipment advantages

- Massaging mechanisms are designed to promote material flow and prevent tearing of the bulk bag

- Bulk bag cross for loading by trolley or elevator

- Height adjustable by locking pin

- 4-sided bulk bag massage set

Features

Technical specification

Management of cylinder strokes by laser sensor to ensure that the bulk bag fabric does not tear

Penetration into the heart of the bulk bag with force distribution on each blank of the bulk bag.

| Manufacturing materials |

painted/galvanized steel, stainless steel 304L, stainless steel 316L |

|---|---|

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Pressure | Up to 100 bar |

| TOR input | 16 |

| TOR output | 6 |

| Maximum size (Length * Width * Height) | 1,300 x 1,300 x 2,000 mm |

Operation procedure:

Average duration of a total cycle: 5 min

1. Attach the bulk bag to the handling cross

2. Handle the cross by trolley or hoist

3. Remove the bulk bag in the cage and close the door

4. Beginning of the massage cycle with elevation of the bulk bag

(by hoist or lifting table)

5. End of the cycle and opening of the door

6. Evacuate the bulk bag by forklift or hoist

Dimensions :

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Raw materials deconditioning line

Processed powders: sugar and salt - Raw materials deconditioning line - The installation concerns a premix preparation line for the food industry.Food and Animal Feed